Intelligent belt conveyor roller

A belt conveyor, intelligent technology, applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve problems such as difficult to analyze and improve the impact of rollers, and achieve the effect of improving management level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

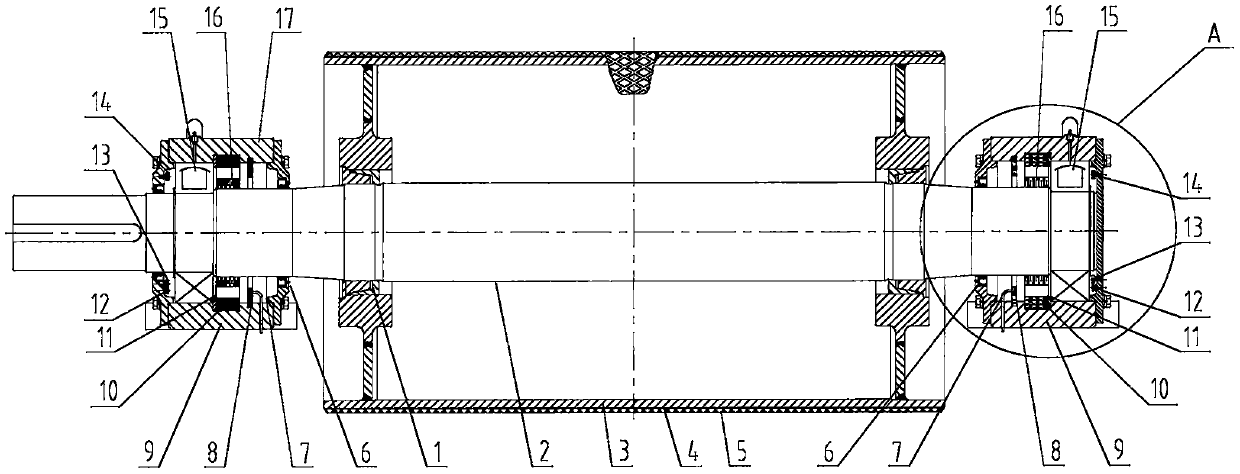

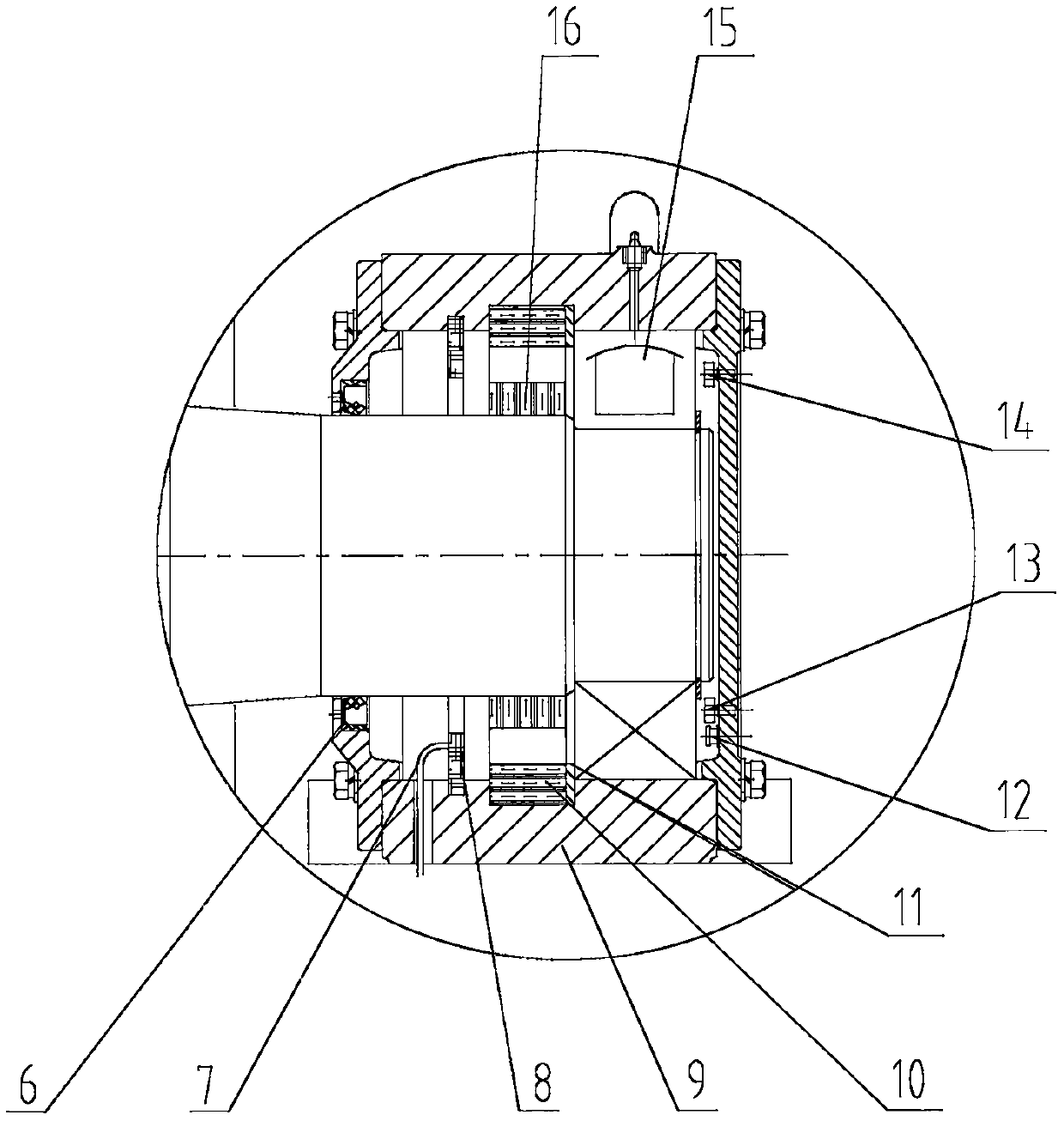

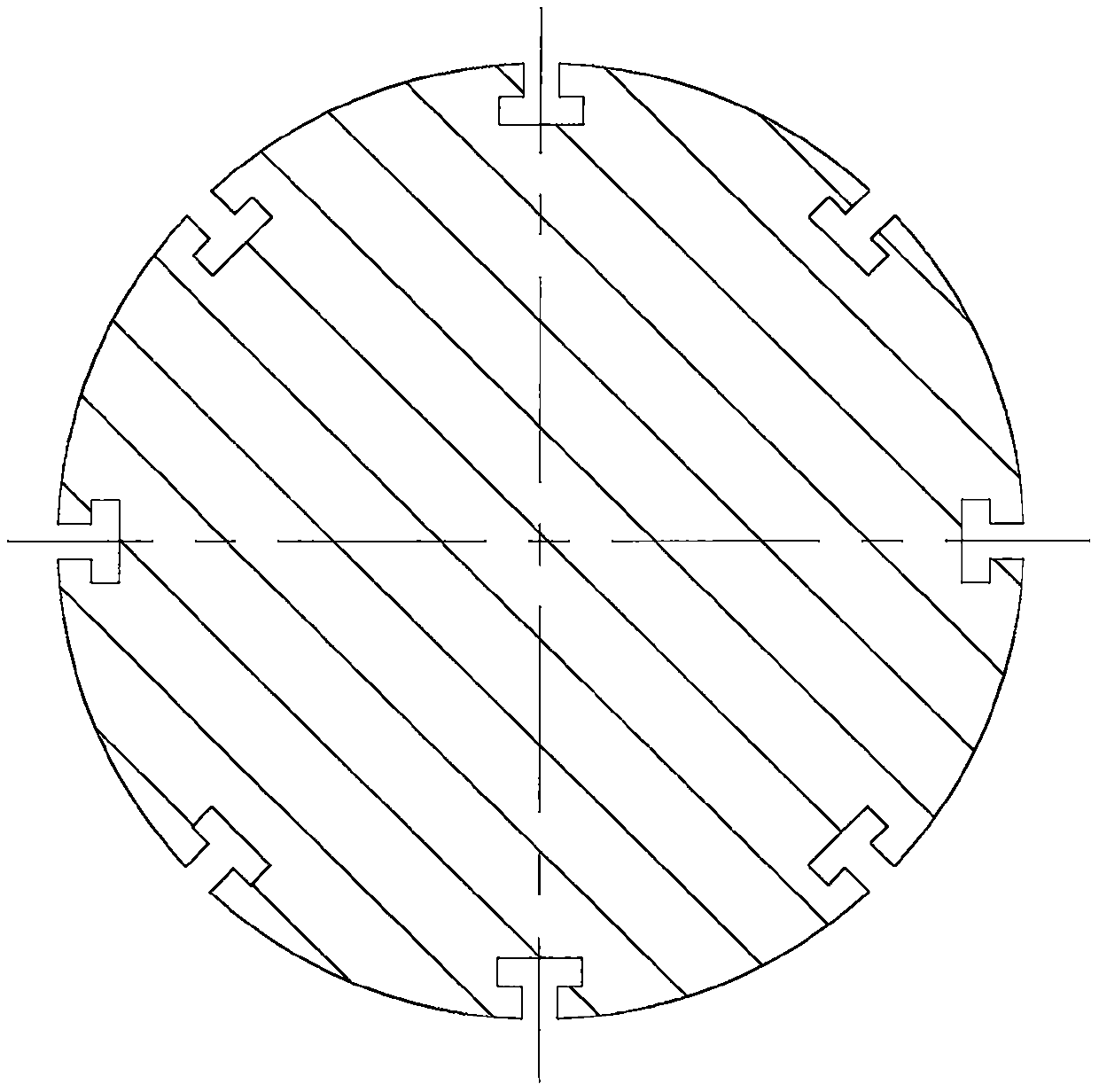

[0012] The intelligent belt conveyor roller of the present invention includes an expansion sleeve 1, a shaft 2, a cylinder body 3, a primer 4, a surface glue 5, a sealing ring 6, a communication cable 7, a circuit board 8, a sealing end bearing seat 9, and a stator 10 , retaining ring 11, microphone head 12, vibration sensor 13, temperature sensor 14, bearing 15, permanent magnet 16 and drive end bearing seat 17. The shaft 2 is installed on the cylinder body 3 through the expansion sleeve 1, and the outer surface of the cylinder body 3 is covered with primer 4 and surface glue 5 respectively. Both the end bearing seat 9 and the driving end bearing seat 17 are equipped with a sealing ring 6 and a retaining ring 11, and the stator 10 is installed on the end bearing seat 9 and the driving end bearing seat 17 through a rectangular groove, and then poured epoxy resin to fix it and Insulation, the permanent magnet 16 is installed and fixed on the shaft 2 through a T-shaped keyway; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com