Bulk head of dry slag bulk machine

A bulk head and bulk machine technology, applied in conveyors, loading/unloading, transportation and packaging, etc., can solve the problems of easy flying of dry ash, easy ash overflow from sealed tankers, serious dust, etc., to maintain environmental cleanliness , to avoid the effect of long alignment time and isolation of dust spillage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

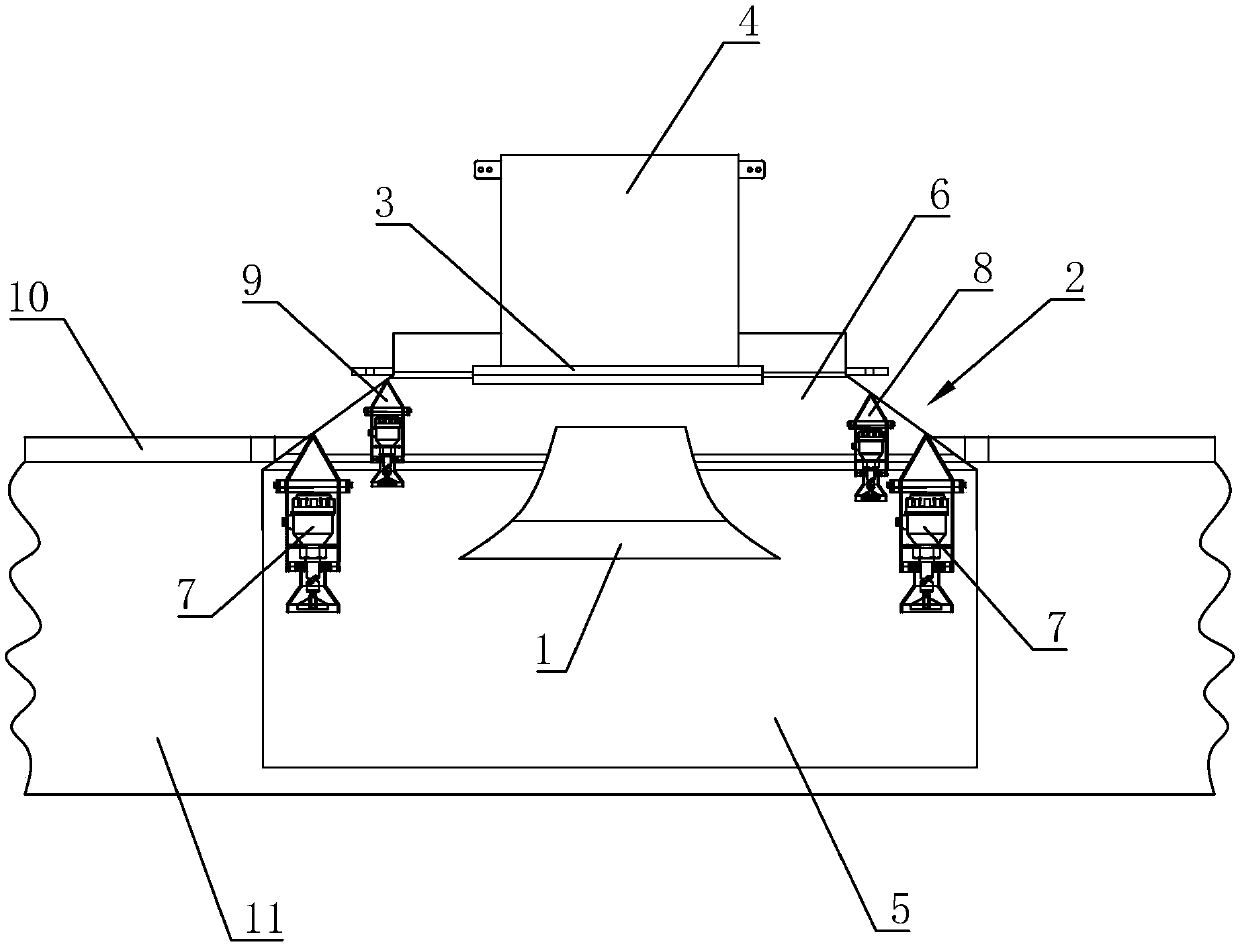

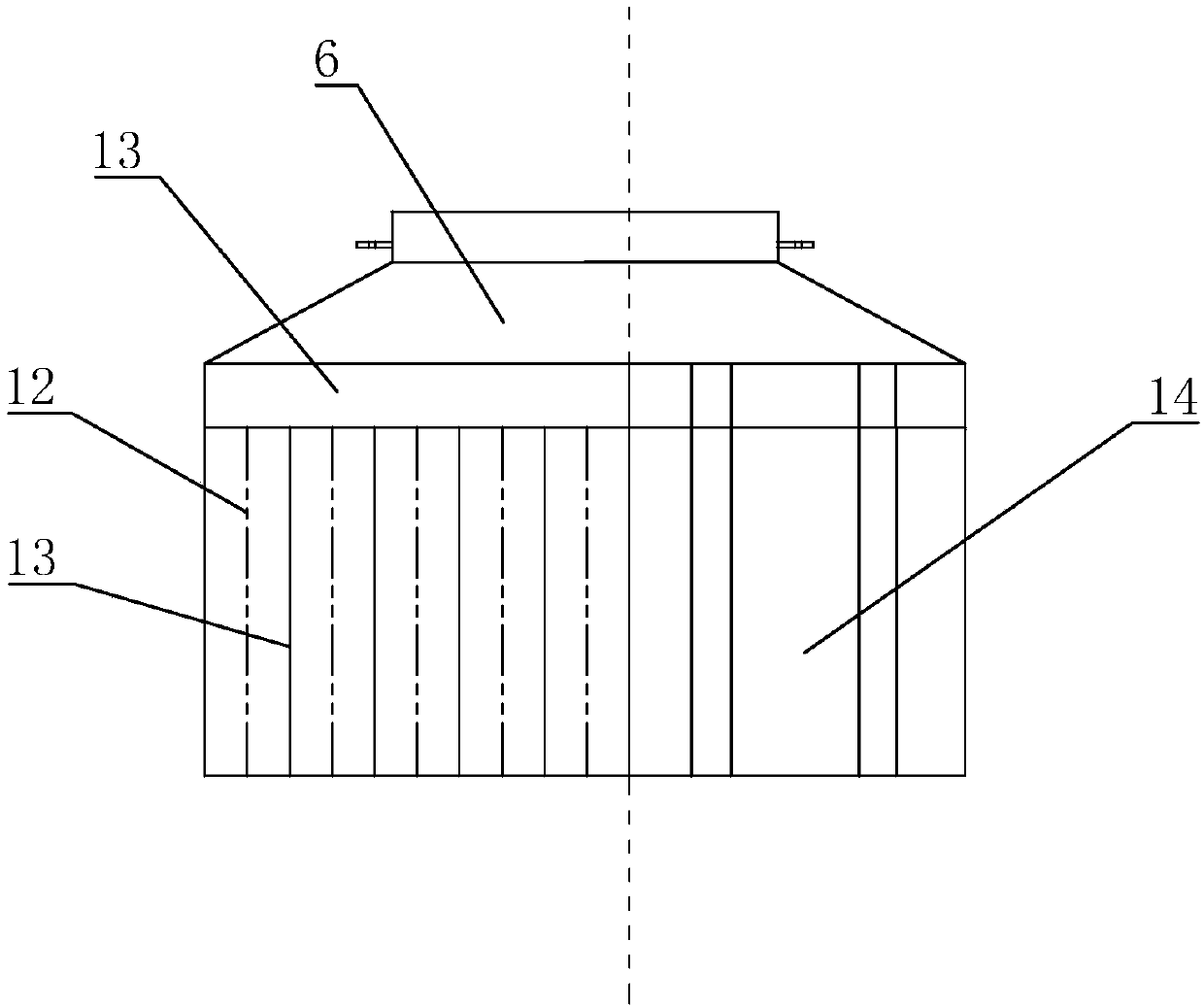

[0033] Embodiment 1: refer to figure 1 , is a bulk head of a dry slag bulk machine disclosed in this embodiment, including an inner cylinder 1 and an outer cylinder 2, the top of the inner cylinder 1 is fixedly connected to the inner wall of the outer cylinder 2 through four support rods (not shown in the figure) , the four poles all extend radially along the inner cylinder 1 and are evenly distributed circumferentially on the top of the inner cylinder 1 . The top center of the outer cylinder 2 is fixed with a flange 3 through four poles, and the telescopic joint 4 is fixedly connected with the flange 3 so as to keep fixed with the top center of the outer cylinder 2 . The inner cylinder 1 is in the shape of a hollow quadrangular platform with a small upper end and a larger lower end, and the four sides of the inner cylinder 1 are all concave arc-shaped surfaces. The diameter of the upper end of the inner cylinder 1 is smaller than the diameter of the telescopic joint 4, the t...

Embodiment 2

[0041] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the inner cylinder 1 is in the shape of a hollow truncated circular cone with a small upper end and a large lower end.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com