Polymerized iron-titanium silicate sulfate inorganic polymer composite flocculant, its preparation and application

An inorganic polymer and composite flocculant technology, applied in the field of environment and chemistry, can solve the problems of short storage time and achieve long storage time, good flocculation effect and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

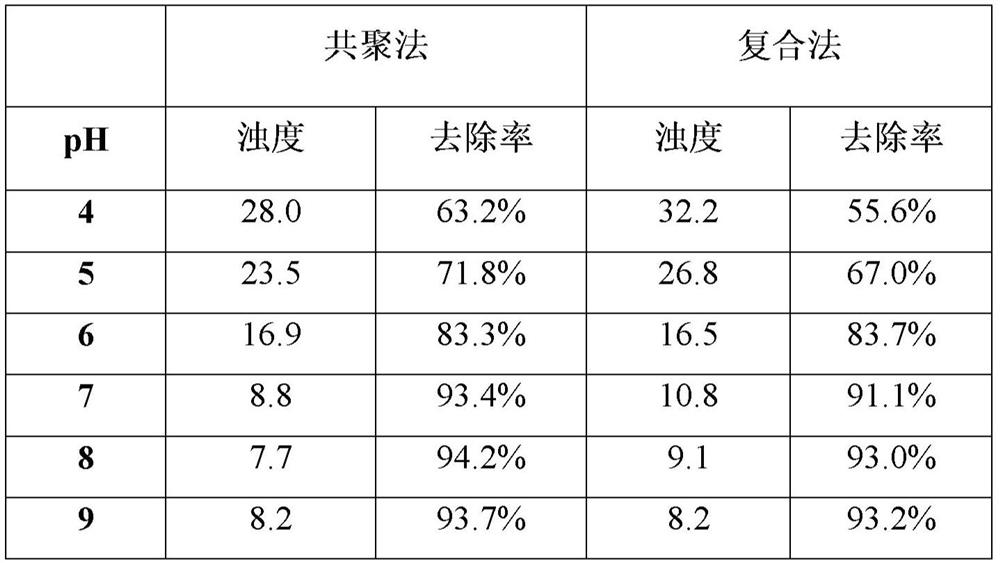

Examples

preparation example Construction

[0024] The invention also discloses a preparation method of polysilicate iron titanium sulfate inorganic polymer composite flocculant, the steps are as follows:

[0025] (1) Pass the 26 mesh sieve after pulverizing the ilmenite sample, adopt the concentration of 5%-98% H 2 SO 4 solution to leach Fe, Ti and other metal elements in ilmenite, and add a certain amount of NaClO to the acid leaching solution 3 Will Fe 2+ converted to Fe 3+ .

[0026] (2) Add TiCl to the pickling solution according to the expected molar ratio of Ti / Fe 1:1~1:10 4 , stirred for 0.5h to make Ti 4+ with Fe 3+ fully responsive.

[0027] (3) The concentration is that the sodium silicate solution of 18~37wt% is added dropwise in the dilute hydrochloric acid that concentration is 0.5~1 mol / L, controls the pH of solution in the whole reaction process<2, and the final pH of adjustment solution is 1.5 , to obtain polymeric silicic acid solution;

[0028] (4a) Immediately measure a certain volume of iro...

Embodiment 1

[0040] (1) Weigh 15g ilmenite, add sulfuric acid with a volume fraction of 20% according to the solid-to-liquid ratio of 3:4, take out the pickling solution after shaking and stirring for 24 hours; Dosing TiCl 4 , stirred for 0.5h to make Ti 4+ with Fe 3+ fully responsive.

[0041] (2) Weigh 10.0g Na 2 SiO 3 9H 2 Dissolve O liquid in about 100mL of water, add it dropwise to dilute hydrochloric acid with a concentration of 0.5-1mol / L, adjust the pH with dilute hydrochloric acid to always be less than 2, and control the final pH to 1.5, and set the volume to 500mL to obtain 0.023927mol / L (as SiO 2 meter) of polymeric silicic acid solution;

[0042] (3) Immediately add the fresh polysilicic acid solution in step (2) to the iron-titanium sulfate solution in step (1) until the Si / Ti ratios are 0.02, 0.05, 0.07, 0.1 (for comparison) , and adding a concentration of 10 wt% Na 2 CO 3 The solution was stirred for 2 hours until the degree of alkalization was 2.0, and after sta...

Embodiment 2

[0045] The steps are the same as in Example 1, the only difference is that in step (1), TiCl is added to the pickling solution according to the Ti / Fe molar ratio of 1:1. 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com