Compound solid lubricating block and preparation method thereof

A lubricating block and solid material technology, applied in lubricating compositions, petroleum industry, etc., can solve the problems of increasing operating costs of stone processing enterprises, high processing equipment and processing costs, affecting product market competitiveness, etc., to achieve excellent lubricating effect, Reduce material cost, good anti-friction lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

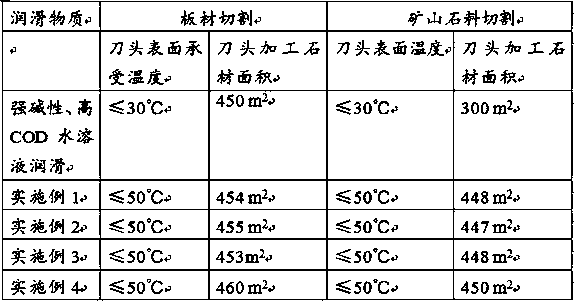

Examples

Embodiment 1

[0022] Composition: 100g of hydrocarbon solid material, 50g of polytetrafluoroethylene, 100g of chlorinated paraffin, 200g of flake micropowder, 50g of lithium stearate, 0.1g of fluorocarbon surfactant, 100g of filler; the hydrocarbon solid material includes 40g of C35 alkane, 30g of C38 cycloalkane, 30g of C30 olefin, wherein the molecular weight of polytetrafluoroethylene is less than 10000, n=80; the flake micropowder is a mixture of graphite micropowder, silicon micropowder, graphene micropowder and boron carbide micropowder with a particle size of 70 μm, in which: graphite Micropowder 60g, silicon micropowder 50g, graphene micropowder 62g, molybdenum disulfide 8g and boron carbide micropowder 20g. The fluorocarbon surfactant is a mixture of 0.033g sodium perfluorooctanoate and 0.067g sodium perfluorooctane sulfonate; the filler is a mixture of 50g talcum powder and 50g mica powder with a particle size of 8 μm.

[0023] The preparation method comprises the following steps:...

Embodiment 2

[0029] Composition: 300g of hydrocarbon solid material, 100g of polytetrafluoroethylene, 150g of chlorinated paraffin, 400g of flaky micropowder, 100g of lithium stearate, 1g of fluorocarbon surfactant, and 300g of filler. Among them, the hydrocarbon solid materials include solid alkane C40 alkane 180g, cycloalkane C38 cycloalkane 90g, olefin C30 olefin 30g, and its average molecular weight is 300-1000; polytetrafluoroethylene molecular weight <10000, n=80. The flaky micropowder is a mixture of graphite micropowder, silicon micropowder, graphene micropowder and boron carbide micropowder with a particle size of 60 μm, wherein, graphite micropowder 160g, silicon micropowder 80g, graphene micropowder 100g, molybdenum disulfide 8g and boron carbide micropowder 52g. The fluorocarbon surfactant is a mixture of 0.5g sodium perfluorooctanoate and 0.5g sodium perfluorooctane sulfonate; the filler is a mixture of 150g talcum powder and 150g mica powder with a particle size of 5 μm.

[0...

Embodiment 3

[0036] Composition: 100g of hydrocarbon solid material, 50g of polytetrafluoroethylene, 100g of chlorinated paraffin, 200g of flake micropowder, 50g of lithium stearate, 0.1g of fluorocarbon surfactant, 50g of filler and 30g of auxiliary agent; among them, hydrocarbon solid The material is a mixture of solid alkanes, cycloalkanes and alkenes, among which, solid alkanes are 50g, cycloalkanes are 30g, and alkenes are 20g, and their average molecular weight is 300-1000; solid alkanes are C40 alkanes, cycloalkanes are C38 cycloalkanes, and olefins are C30 alkenes . The molecular weight of polytetrafluoroethylene is <10000, n=60. Among them, the flake micropowder is a mixture of graphite micropowder, silicon micropowder, graphene micropowder and boron carbide micropowder with a particle size of 60 μm, wherein, graphite micropowder 70g, silicon micropowder 50g, graphene micropowder 50g, molybdenum disulfide 6g and boron carbide micropowder 24g . Among them, the fluorocarbon surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com