Building cement pile stabilizing device

A stabilizing device and cement pile technology, applied in construction, sheet pile wall, foundation structure engineering and other directions, can solve the problems of non-existence, inclination of cement piles, weakening the effect of stable foundation, etc., and achieve the effect of good stability and protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

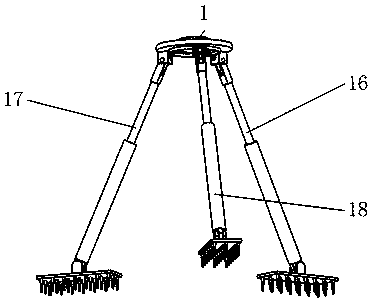

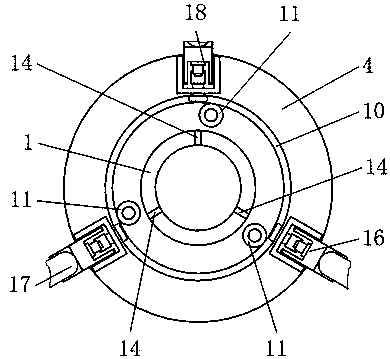

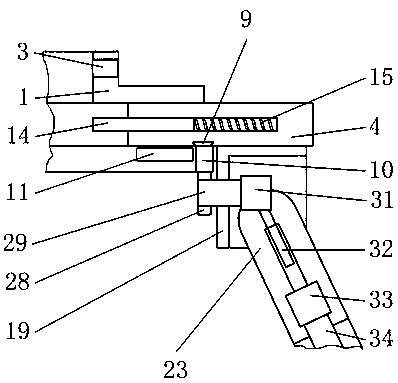

[0049] Such as figure 1 , 2 , 3, it includes a positioning ring 1, an annular cutout 2, a positioning threaded hole 3, a trigger ring 4, a rack chute 5, a gear groove 6, a first shaft hole 7, an annular trapezoidal chute 8, and an annular trapezoidal slide bar 9. Gear ring 10, second gear 11, first transmission shaft 12, first gear 13, transmission rack 14, first return spring 15, first support mechanism 16, second support mechanism 17, third support mechanism 18 , where as Figure 4 , 8 As shown, the upper end of the outer circle of the positioning ring 1 is provided with an annular notch 2 along the circumferential direction, and the annular notch 2 communicates with the upper end surface of the positioning ring 1; the side wall of the annular notch 2 is uniformly provided with three positioning threaded holes 3 along the circumferential direction; Such as figure 1 As shown, the positioning ring 1 is nested on the upper end of the cement pile and fixed on the cement pile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com