Disassembly and assembly method of oil and gas bushing connecting AC 500kv oil-immersed transformer and gis tubular busbar

A technology for oil-immersed transformers and oil and gas bushings, which is applied to the on-site preparation of electrical components, switchgear, and building components, can solve the problems of affecting the service life of equipment, inconvenient adjustment and control, and high risk of scaffolding accidents, and achieves a high level of improvement. Installation quality and work efficiency, convenient and stable protection, and the effect of eliminating hidden dangers of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

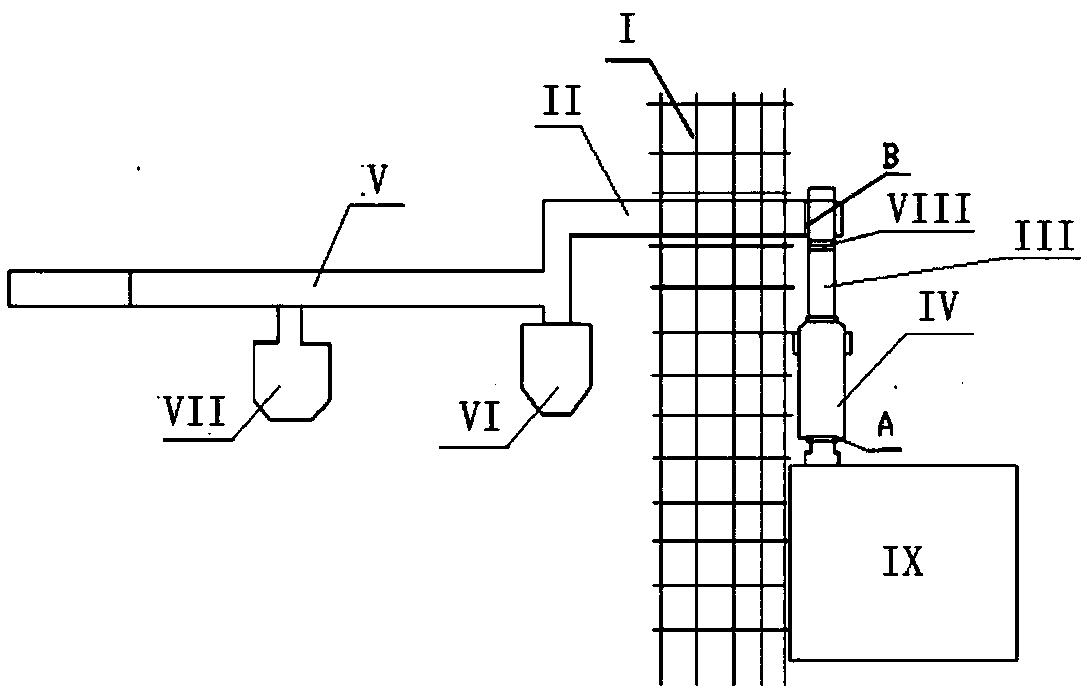

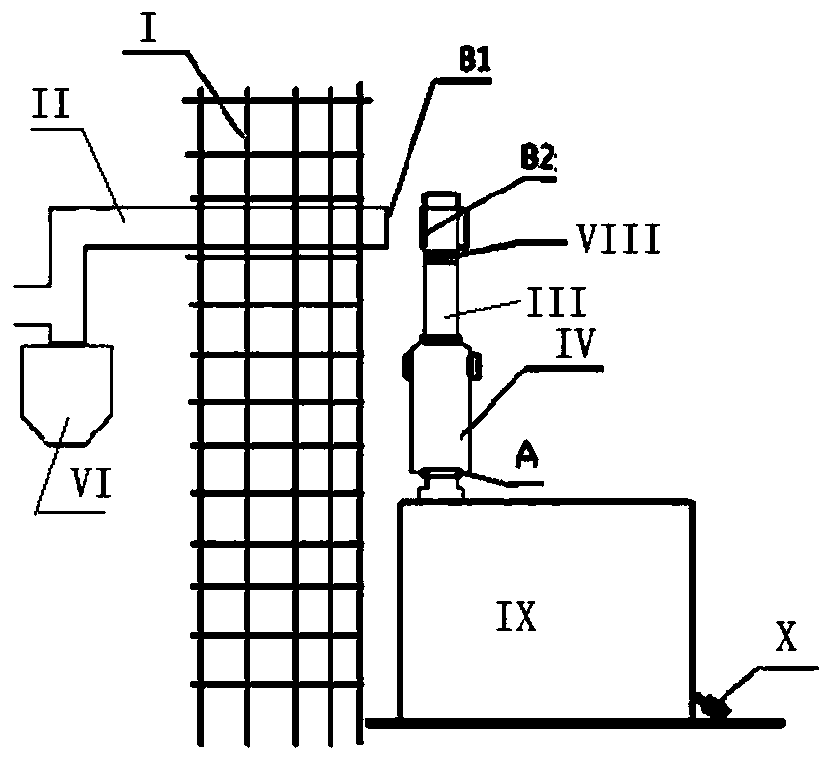

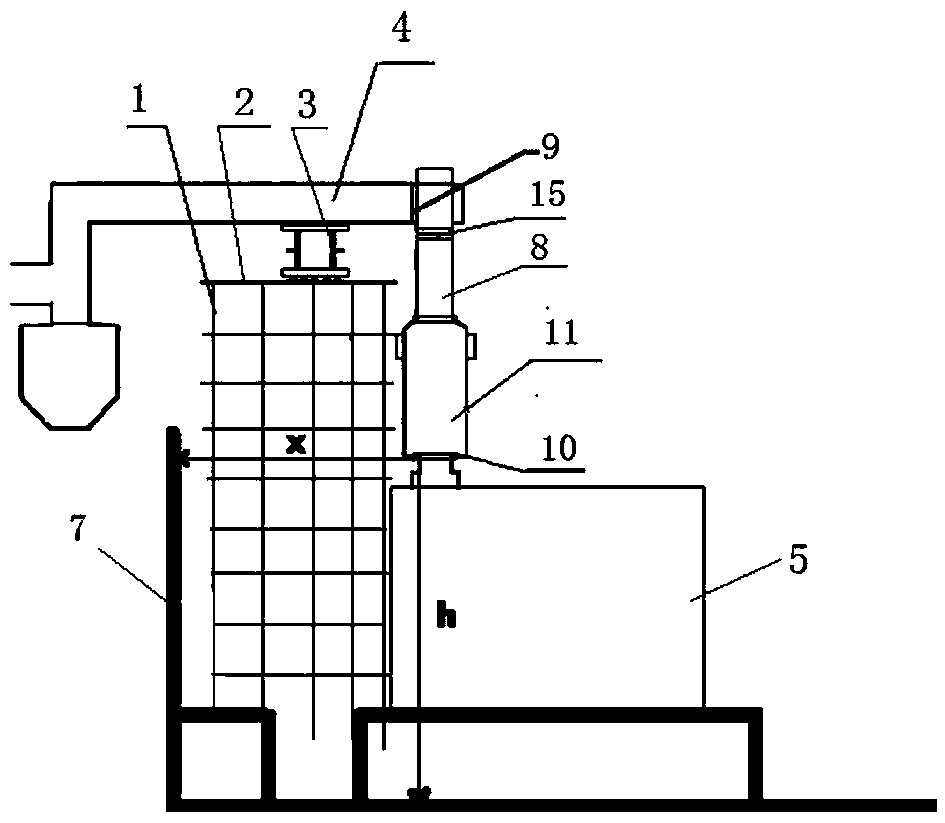

[0030] Disassembly method of oil and gas bushing for connecting AC 500kV oil-immersed transformer and GIS tubular busbar, such as image 3 , Figure 4 , Figure 5 As shown, the method steps are as follows:

[0031]a. Use a load-bearing scaffold to build a support frame 1, lay a plank 2 on the top of the support frame, and place a height-adjustable support adjustment device 3 on the plank to support the GIS tubular busbar 4, the tubular busbar GIS air chamber and Gas recovery is carried out in relevant air chambers such as arrester air chambers, TV air chambers and other related air chambers connected to the GIS air chamber of the tubular busbar;

[0032] b. Mark the positions of the longitudinal centerline 5-1 and the transverse centerline 5-2 of the old oil-immersed transformer 5 to be replaced on the oil pool wall 6 of the oil-immersed transformer;

[0033] c. Taking the firewall 7 at the end of the oil-immersed transformer and the firewall 7' on one side and the ground a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com