Cooling blades and cooling fans

A heat dissipation fan and fan blade technology, which is applied in the direction of non-variable pumps, pump components, and parts of pumping devices for elastic fluids, etc., can solve high-frequency noise, increase the overall weight of centrifugal fans, and plastic fan blades Difficult to thin the thickness and other issues, to achieve the effect of the best heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

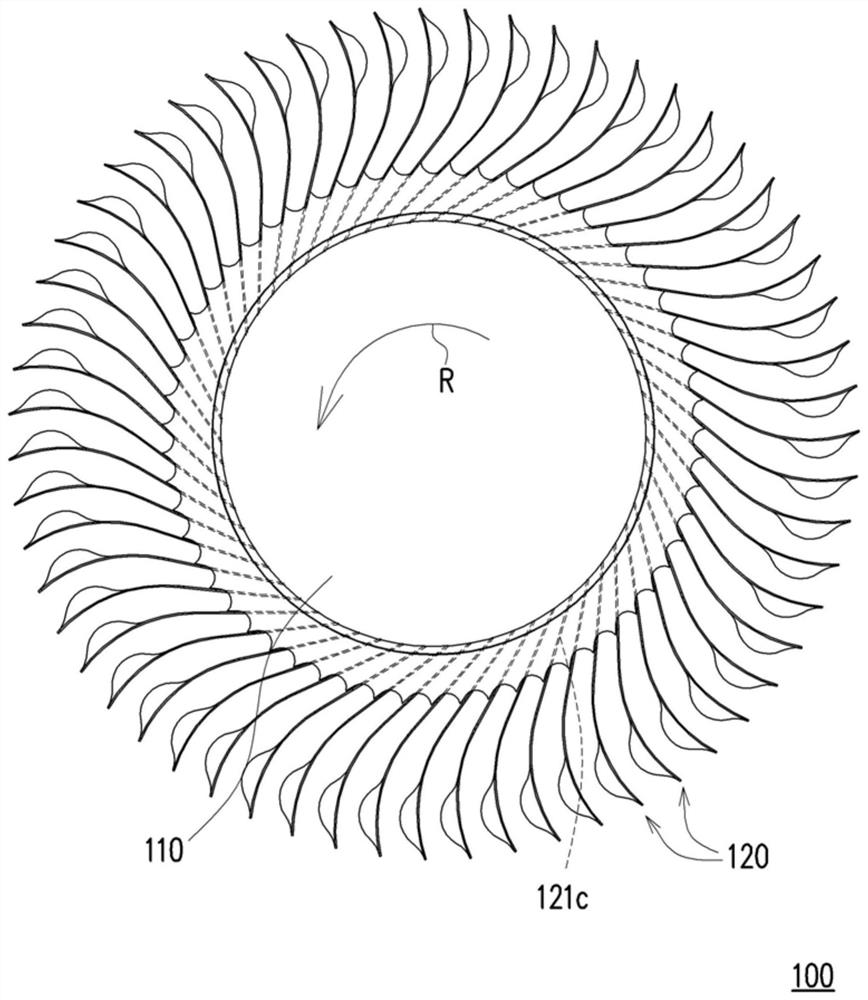

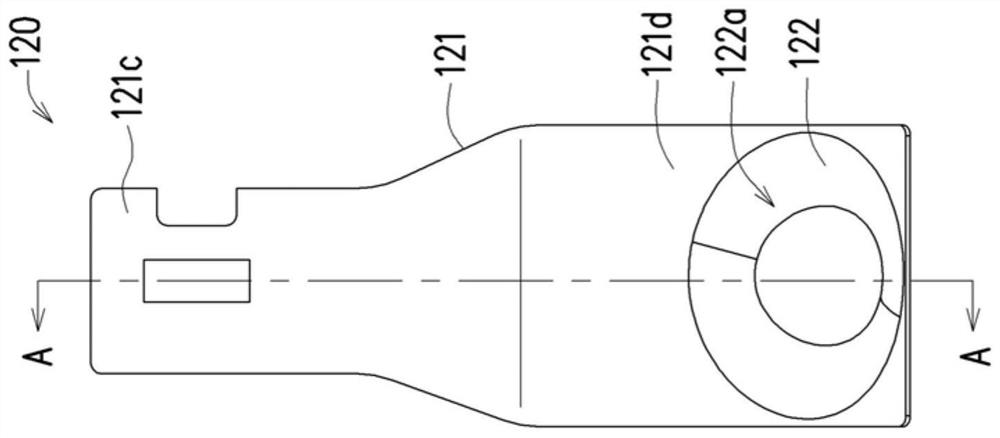

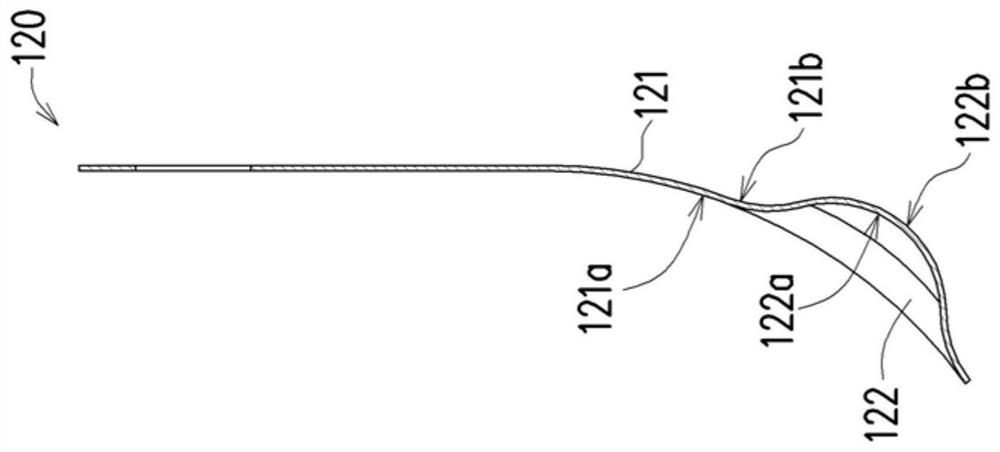

[0038] Figure 1A is a schematic diagram of the cooling fan according to the first embodiment of the present invention. Figure 1B is a schematic diagram of the heat dissipation fan blade according to the first embodiment of the present invention. Figure 1C yes Figure 1B The cross-sectional schematic diagram of the heat dissipation fan blade along the section line A-A. Please refer to Figure 1A to Figure 1C , in this embodiment, the cooling fan 100 can be a centrifugal fan, which includes a hub 110 and a plurality of cooling fan blades 120 , and these cooling fan blades 120 are arranged around the hub 110 . For example, the hub 110 fixed to each other and the cooling fan blades 120 can be manufactured by insert molding technology. In terms of processing, one end of these cooling fan blades 120 will be placed into the mold cavity used to form the hub 110 first, and then the hub 110 will be formed in the mold cavity by injection molding technology, so as to fix the cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com