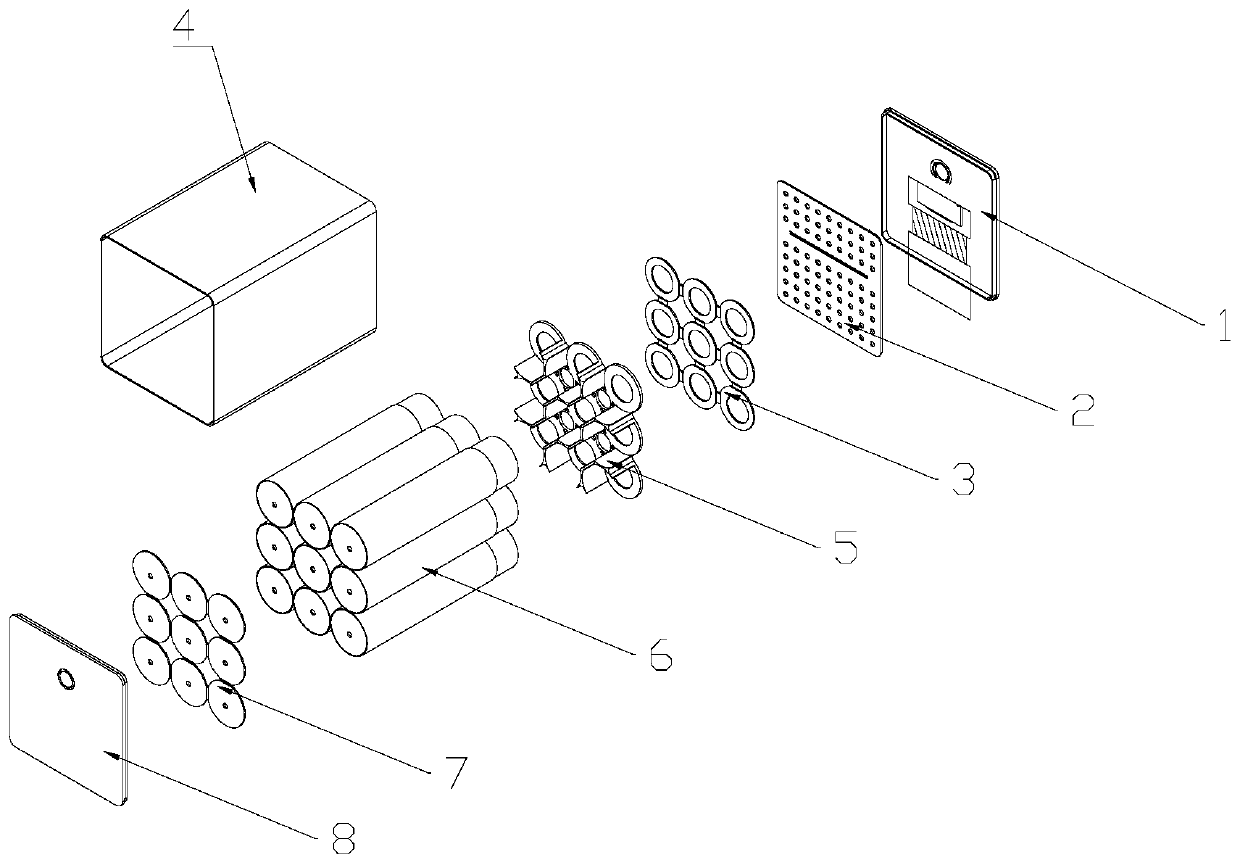

High-capacity battery with parallel network and manufacturing method of high-capacity battery

A manufacturing method and high-capacity technology, which are applied in secondary batteries, battery pack components, capacitor current collector combinations, etc., to achieve the effects of improving charge and discharge rate performance, improving heat dissipation and rate performance, and shortening the conduction path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

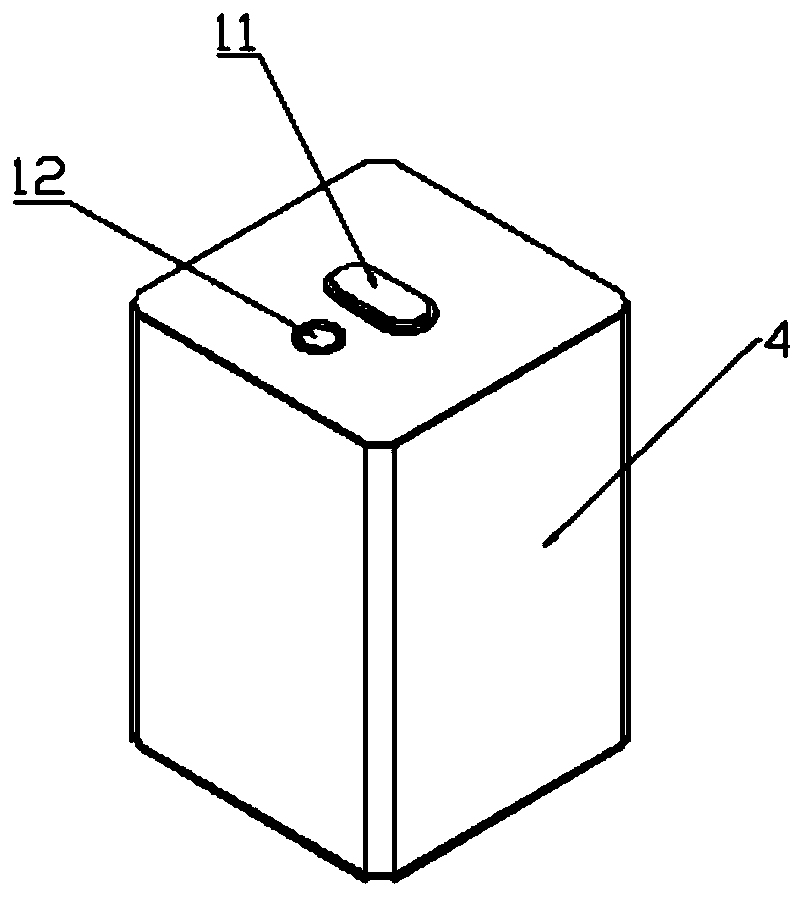

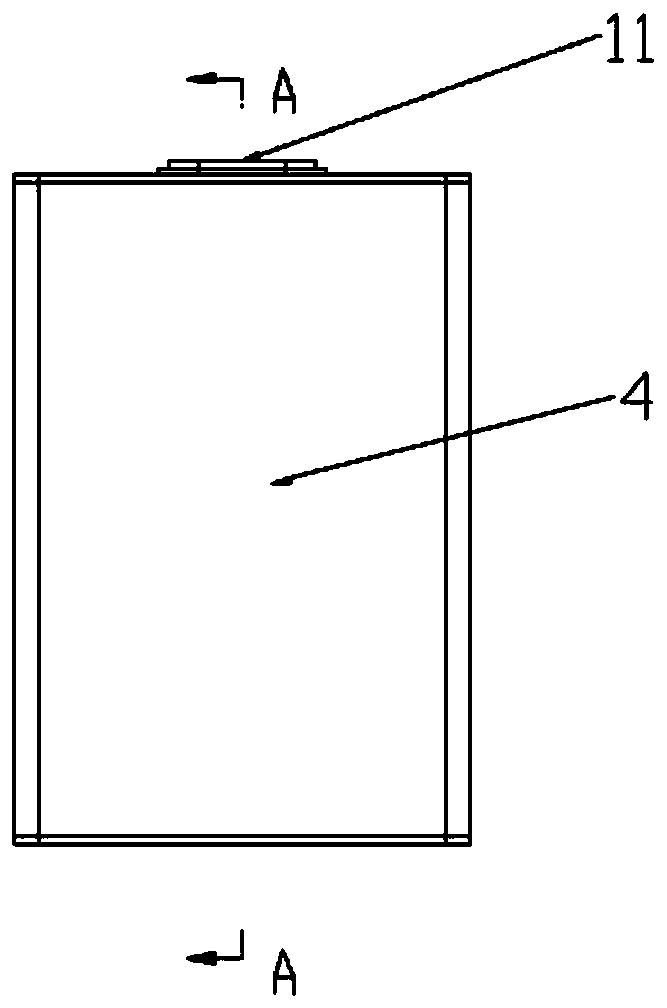

[0090] In the high-capacity battery of the present application, 9 lithium iron phosphate positive electrodes-graphite negative electrode winding cores (diameter 32mm and height 140mm) are used to make a 3.2V135Ah large-capacity battery with the above-mentioned processing method. When one of the winding cores is short-circuited by acupuncture, the connecting strip around the negative pole of the winding core is fused, which prevents thermal runaway of the large-capacity battery. When an external short circuit is made to the large-capacity battery, the negative fuse bus is blown (see Figure 15(1) and 15(2) ), to avoid thermal runaway of the large-capacity battery.

Embodiment 2

[0092] In the high-capacity battery of the present application, 9 nickel-cobalt lithium manganese oxide positive electrodes-graphite negative electrode winding cores (diameter 21mm and height 60mm) are used to make a 3.6V36Ah large-capacity battery with the above-mentioned processing method. When one of the winding cores is short-circuited by acupuncture, the connecting strip around the negative pole of the winding core is fused, which prevents thermal runaway of the large-capacity battery. When an external short circuit is made to the large-capacity battery, the negative fuse bus is blown (see Figure 15(1) and 15(2) ), to avoid thermal runaway of the large-capacity battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com