Pressure reducing valve

A pressure reducing valve and valve body technology, which is applied in safety valves, balance valves, valve devices, etc., can solve the problems of high manufacturing cost, stable pressure and pressure reduction, complex structure, etc., and achieve long service life, reliable pressure reduction effect, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with specific examples and accompanying drawings.

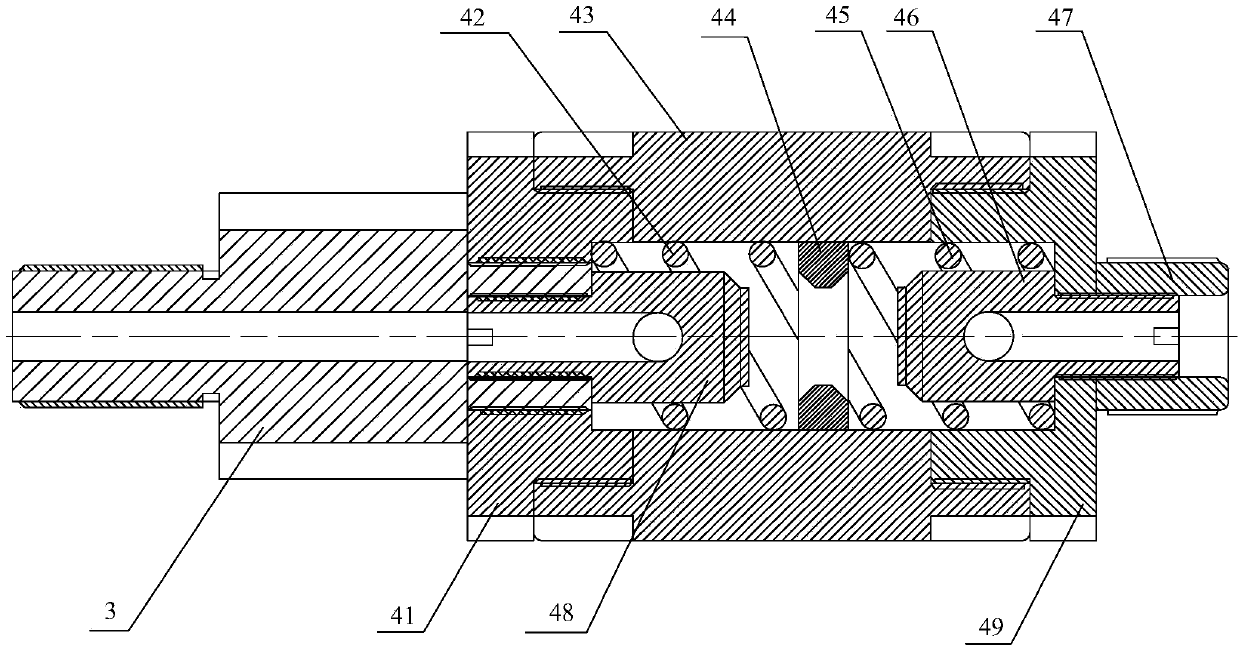

[0020] The present invention as figure 1 As shown, it includes an air inlet 41, a valve body 43, a valve core, an air outlet 49 and an adjusting bolt 47. The valve core is installed inside the valve body 43, and the two ends of the valve body 43 are respectively threaded with the air inlet 41 and the air outlet 49. , the air inlet 41 is connected to the upstream air source through the one-way valve 3 .

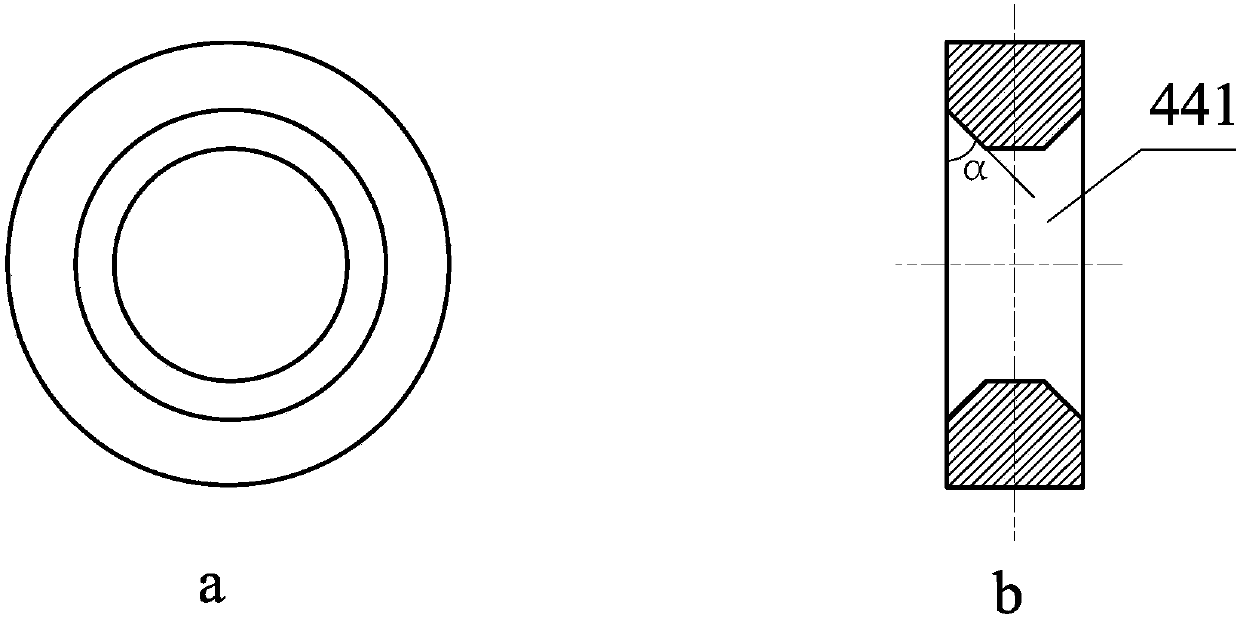

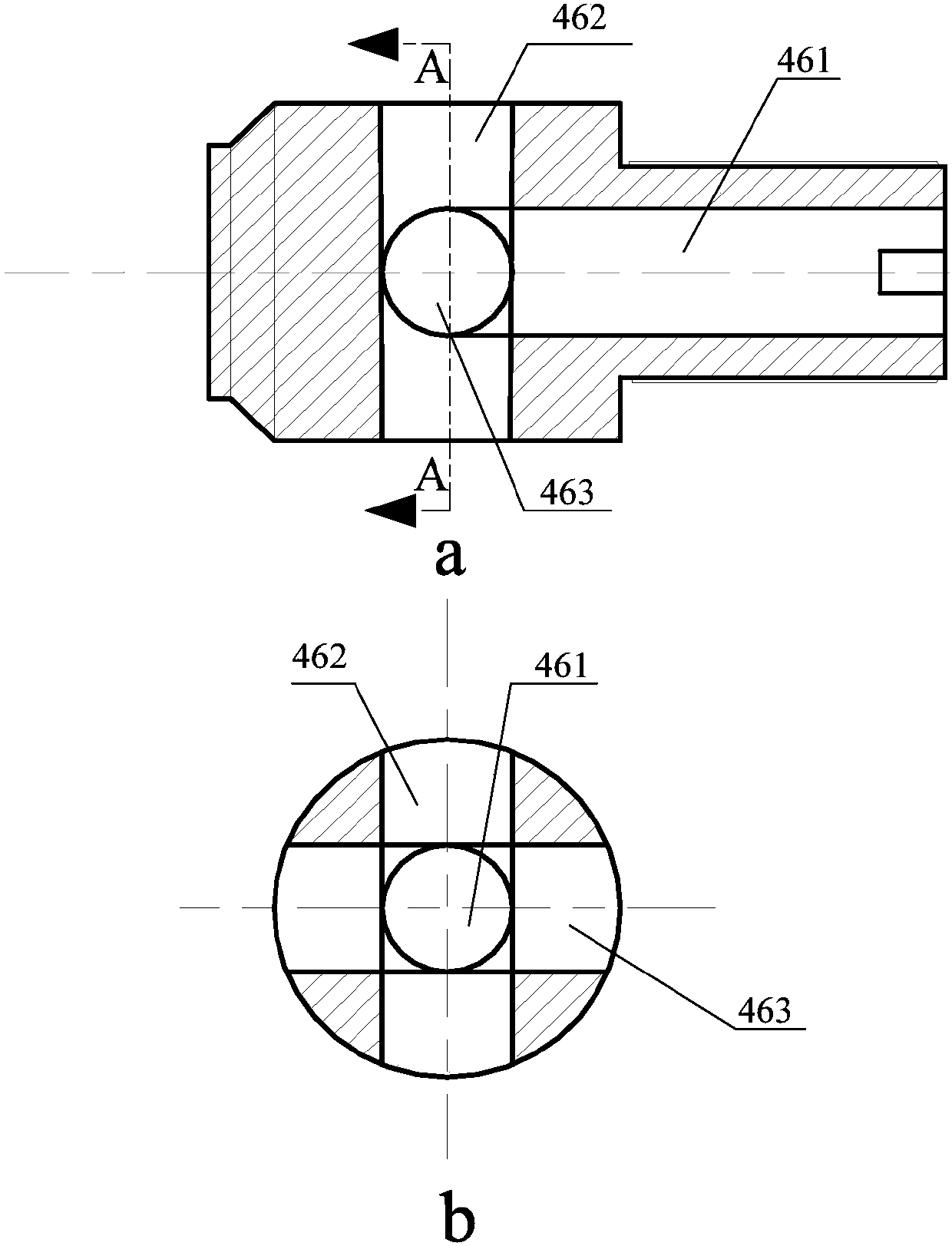

[0021] Spool such as figure 1 As shown, it is composed of an intake flow regulating rod 48, an intake spring 42, a pressure regulating orifice 44, an outlet spring 45 and an outlet flow regulating rod 46. and the air outlet spring 45 are respectively compressed on the two ends of the pressure adjustment orifice plate 44, and are respectively sleeved outside the air intake flow adjustment rod 48 and the air outlet flow adjustment rod 46. The air i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com