A solar vacuum tube with self-cleaning inner tube scale function

A solar energy and vacuum tube technology, which is applied to solar collectors, solar thermal energy, solar thermal power generation using working fluids, etc., can solve the problem of the peeling off of the endothermic coating, the reduction of heat exchange efficiency, and the reduction of heat exchange between the endothermic coating and water. efficiency issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

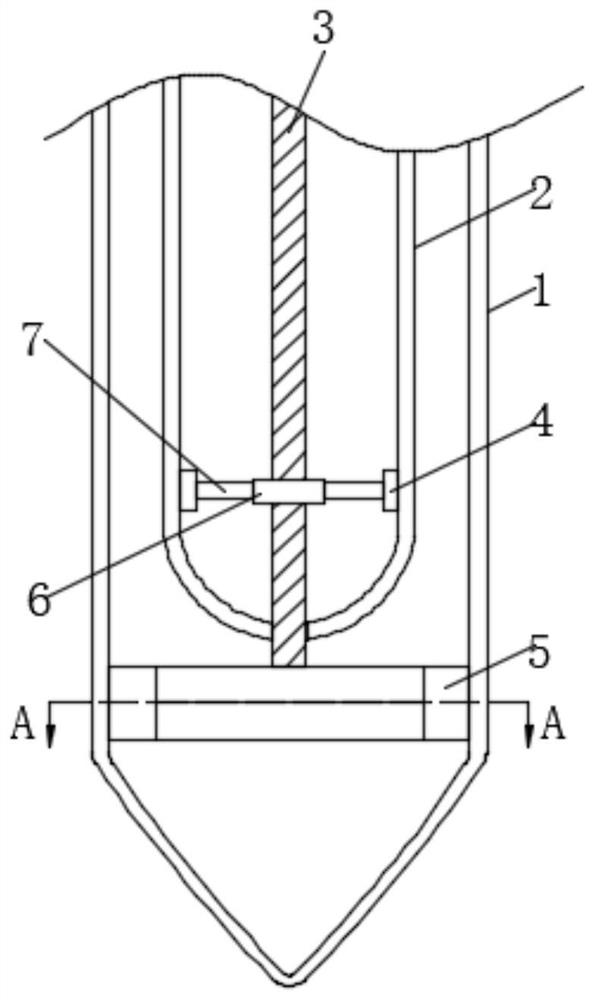

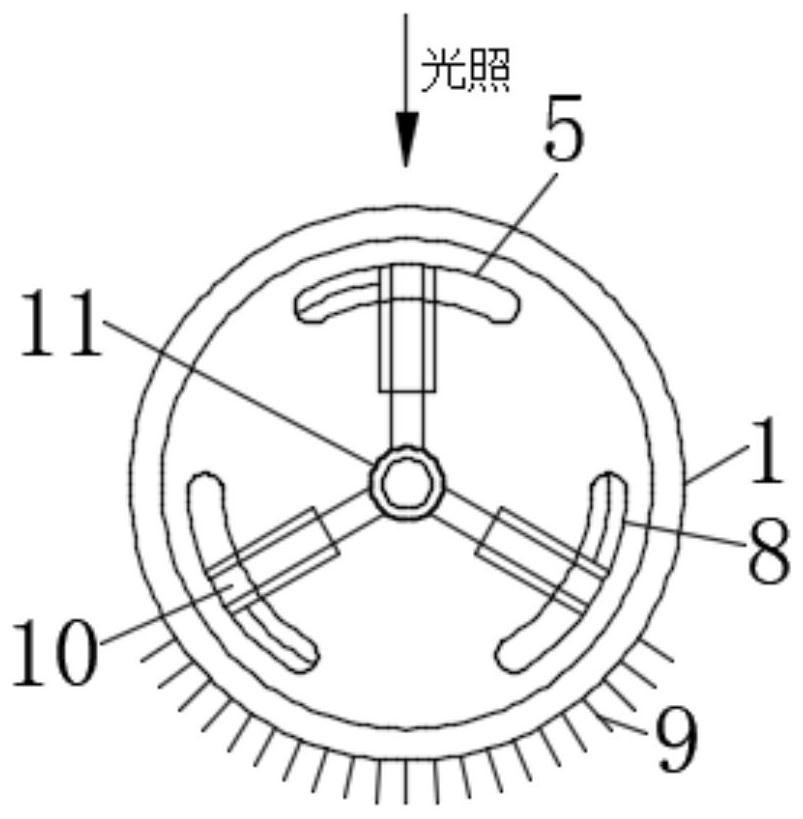

Method used

Image

Examples

Embodiment 2

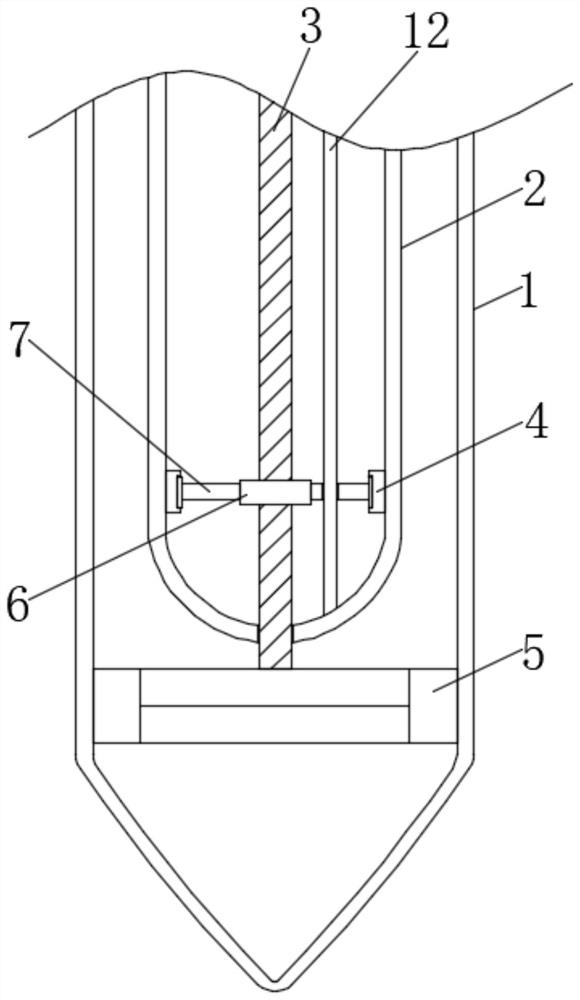

[0022] refer to image 3 , the difference from Example 1 is that the ball screw 3 is made of magnetic material, the inner wall of the metal scraper 4 is provided with an annular groove along its circumference, and an annular ring is slidably connected in the annular groove, and the screw nut 6 passes through the connecting piece 7 is fixedly connected on the inner wall of the annular ring, and the inner bottom of the inner tube 2 is fixedly connected with a guide rod 12 arranged in the vertical direction. The guide rod 12 runs through the connecting piece 7 and is slidably connected with the connecting piece 7.

[0023] In this embodiment, since the ball screw 3 is made of magnetic material, the ball screw 3 will drive the metal scraper 4 to rotate while the ball screw 3 rotates. Under the cooperation of the screw nut 6 and the ball screw 3, the metal scraper 4 It will rotate while moving up, because the water temperature in the inner pipe 2 is higher, and the metal scraper ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com