A three-degree-of-freedom precision adjustment device for a compact back-mounted lens

A precision adjustment, back-mounted technology, applied in the directions of installation, optics, instruments, etc., can solve the problems of low movement accuracy, difficult lens installation, and inability to use precise focus, etc., achieve high adjustment accuracy, reduce device design and difficulty in later adjustment , the effect of reducing the overall complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

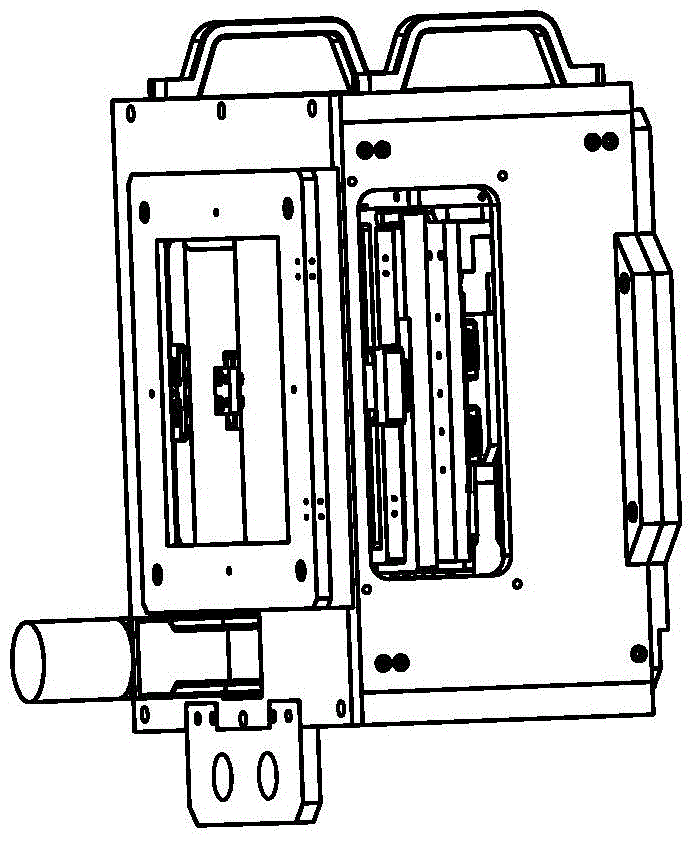

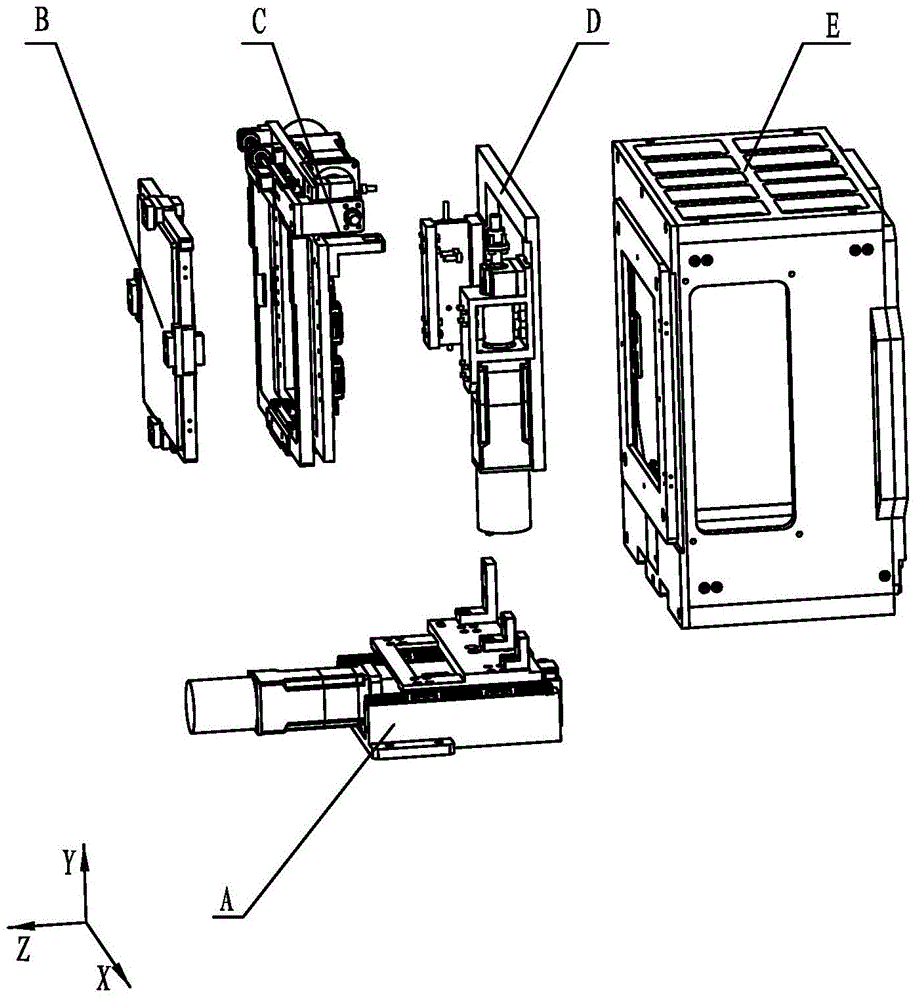

[0023] Specific implementation mode 1. Combination figure 1 Describe this specific embodiment. A three-degree-of-freedom precision adjustment device for a compact back-mounted lens described in this specific embodiment includes a lens clamping module B, an X-direction position adjustment unit C, and a Y-direction position adjustment unit D and Z. To position adjustment unit A and lens case E,

[0024] The lens clamping module B is used to clamp the lens, the lens clamping module B is installed on the X-direction position adjustment unit C, and the X-direction position adjustment unit C is used to drive the lens clamping module B to move in the X direction, The X-direction position adjustment unit C is installed on the Y-direction position adjustment unit D, and the Y-direction position adjustment unit D is used to drive the X-direction position adjustment unit C to move in the Y direction, and the Y-direction position adjustment unit D is installed at the Z-direction position ...

specific Embodiment approach 2

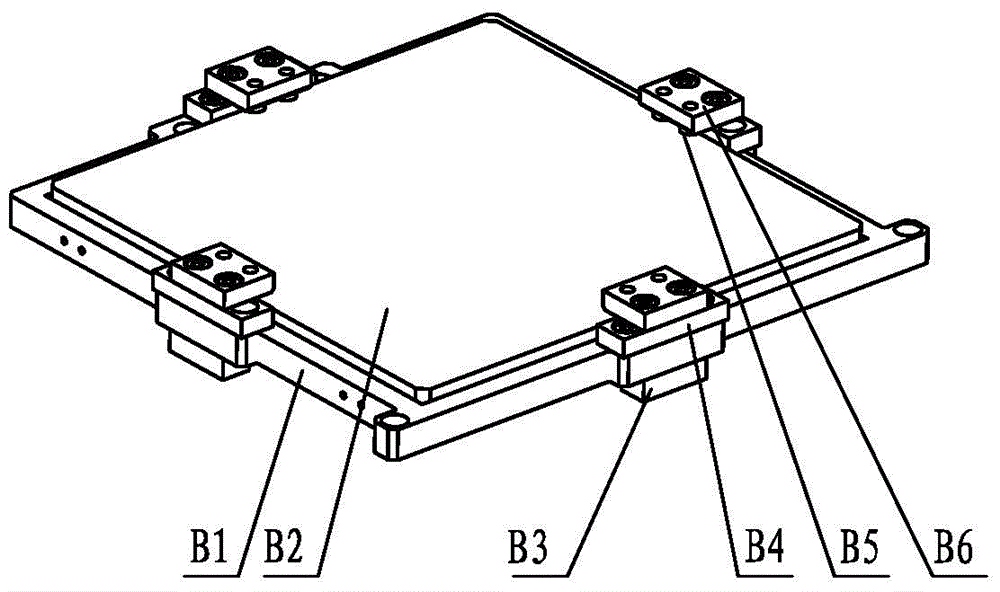

[0026] Specific embodiment two, combine Figure 3-Figure 5 Describe this specific embodiment. The difference between this specific embodiment and the three-degree-of-freedom precision adjustment device for a compact back-mounted lens described in Embodiment 1 is that the lens clamping module B includes a lens support frame B1, Lens B2, lens holding block B3, lens holding block B4, rubber pressing block B5, lens pressing block B6 and elastic washer B7,

[0027] The lens B2 is installed inside the lens support frame B1, and the same side of the four frames of the lens support frame B1 is fixed with a lens pressing block B6, and the lens clamping pad is used between the lens pressing block B6 and the lens support frame B1 B4 is fixed, the bottom of each lens pressing block B6 is fixed with a rubber pressing block B5, and the other side of the three frames of the lens supporting frame B1 is respectively fixed with a lens holding block B3, and each lens holding The top of the bloc...

specific Embodiment approach 3

[0029] Specific embodiment three, combine Figure 6-Figure 7 Describe this specific embodiment. The difference between this specific embodiment and the three-degree-of-freedom precision adjustment device for a compact back-mounted lens described in the second specific embodiment is that the X-direction position adjustment unit C includes a focus lens moving frame C1, X-direction linear motion guide rail C2, X-direction linear motion slider C3, lens holder guide rail C4, X-direction screw rod C5, X-direction connector C6, motion connecting plate C7, X-direction travel trigger C8, X-direction travel switch Support C9, X-direction travel switch C10, Y-direction linear motion guide rail C11, Y-direction linear motion slider C12, Y-direction connector C13, X-direction screw nut C14, X-direction screw bearing seat C15, X-direction bearing seat Block C16, X-direction coupling C17, X-direction drive module support C18, X-direction drive module C19 and Y-direction stroke trigger C20, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com