Rapid calculating method for ballastless track plate based on least square fitting

A ballastless track and least squares technology, applied in the field of fast calculation of ballastless track slabs based on least squares fitting, can solve the problems of slow scanning speed, low calculation accuracy, long data processing time, etc., to reduce modeling time, the effect of shortening the calculation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

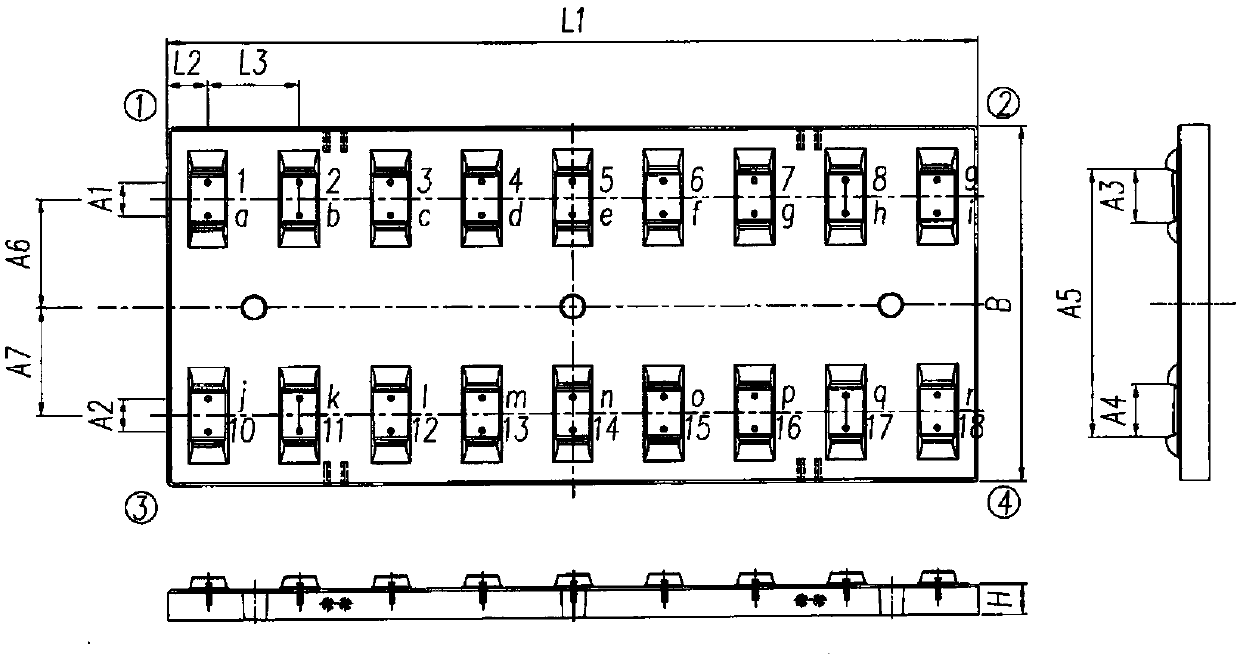

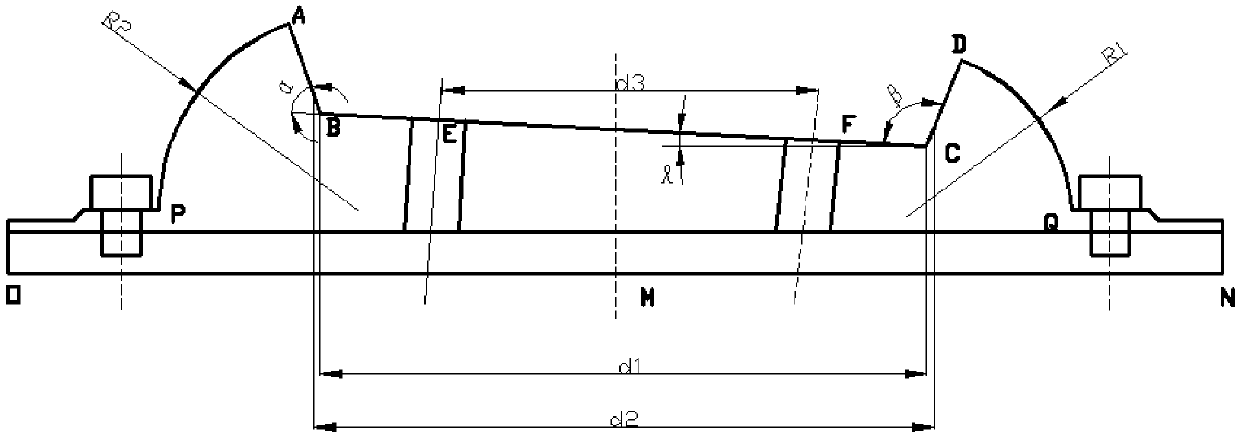

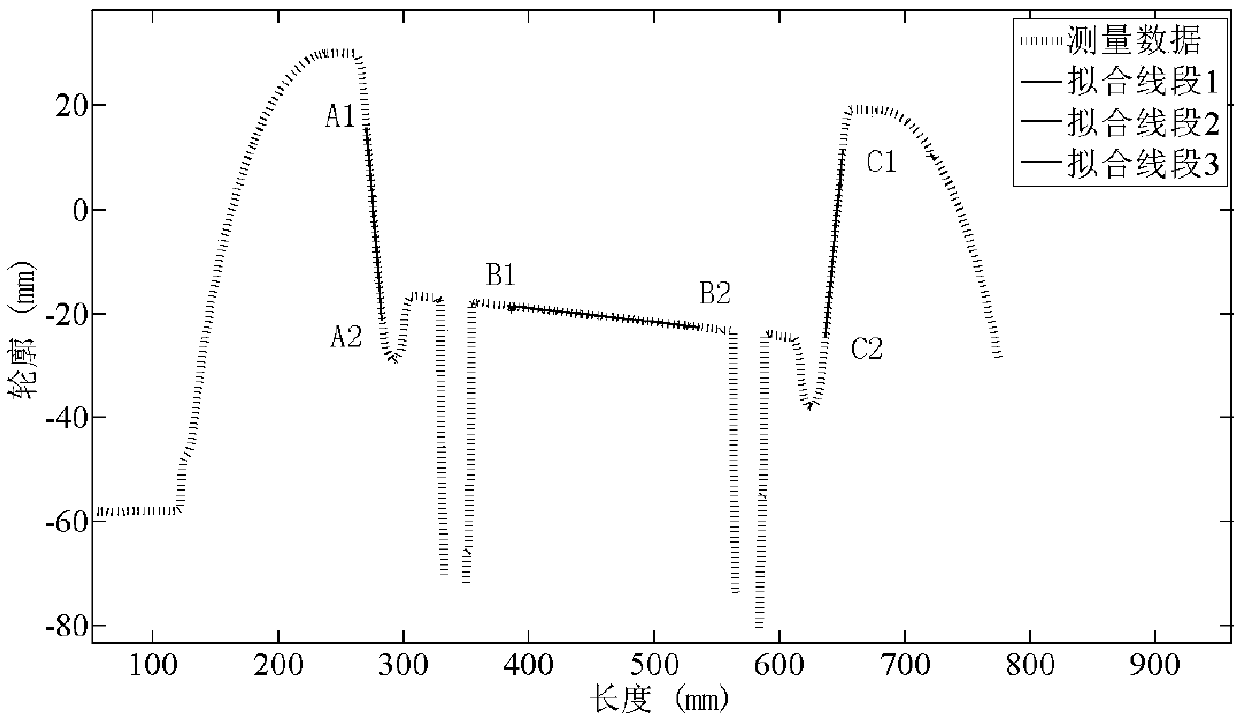

[0037] Based on the least squares method, using a laser scanner to collect such as figure 1 According to the external dimension data of each rail platform of the track slab, find the special position points of the track slab contour line, process the contour data points in segments, and use the least square method to fit, and calculate according to the fitting equation figure 2 Marked size information α, β, γ, d2, d3, where: α: the angle between AB and BC, the angle between the left side of the rail platform and the surface of the rail, β: the angle between DC and BC, the right side of the rail platform The angle between the side and the bearing surface, γ: the angle between the bearing surface and the horizontal plane, corresponding to the calculation of the slope of the bearing surface, d2: the distance between the jaws, d3: the hole distance, respectively corresponding to the outer dimensions of the board (the rail platform The included angle with the rail surface, the slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com