A method of thermal compression test using thermal simulation testing machine

A testing machine and thermal simulation technology, applied in the field of thermal simulation test, can solve the problem that the deformation rate cannot be accurately controlled, and achieve the effect of expanding the research function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

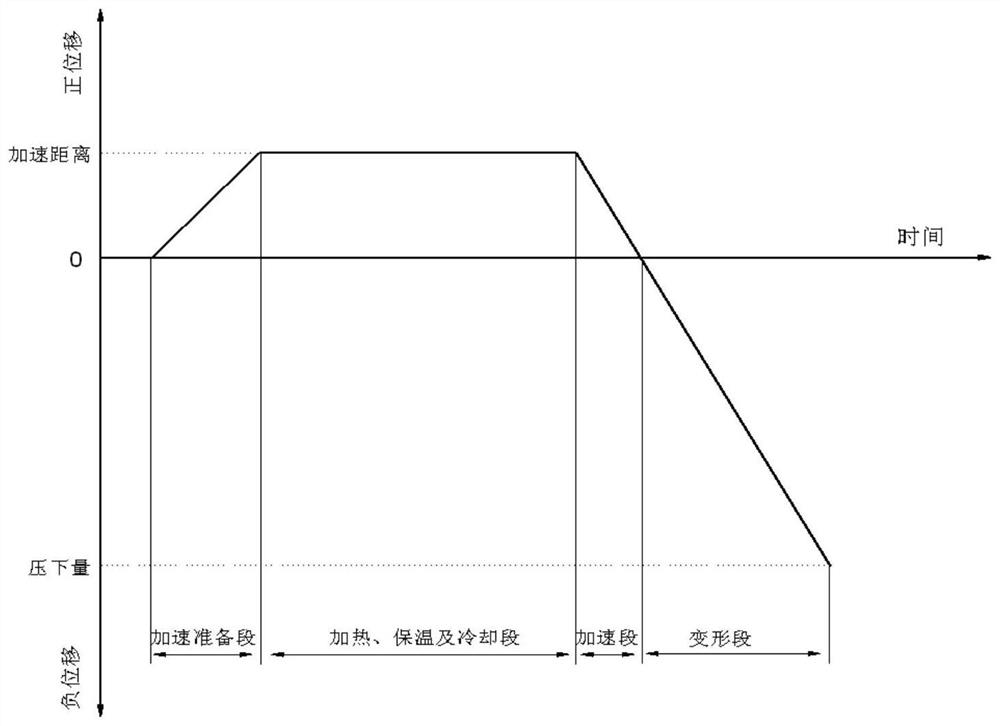

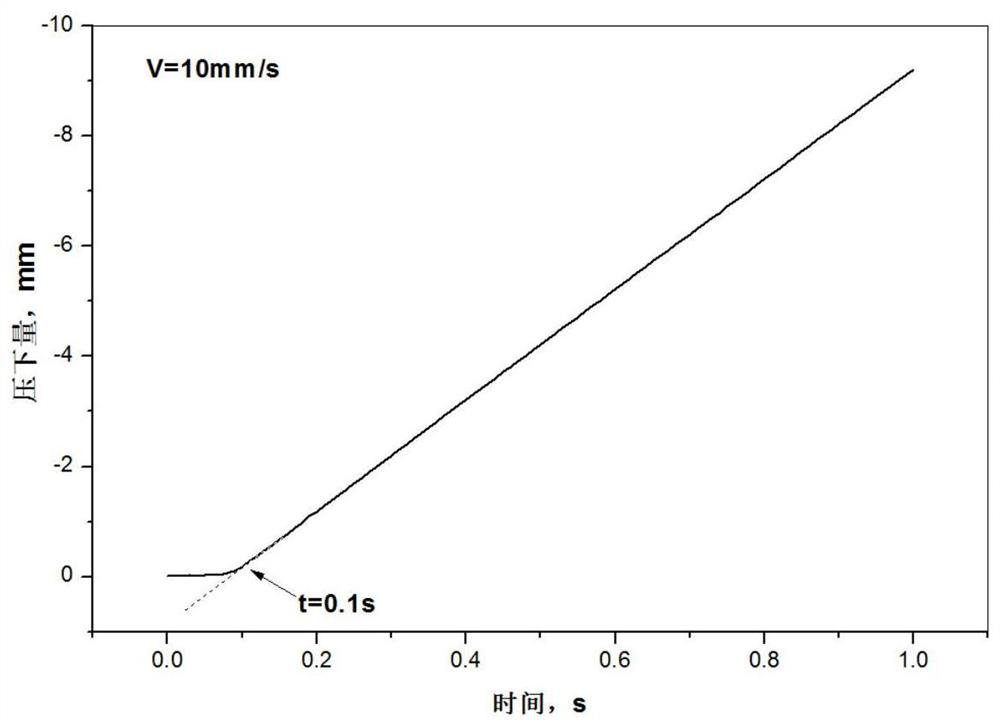

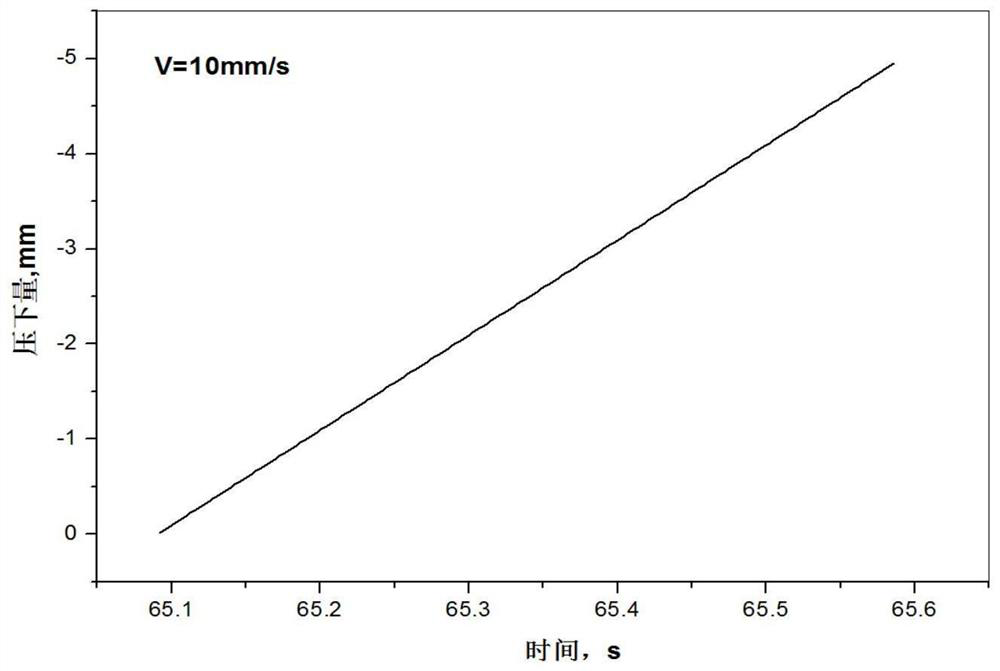

[0034] Embodiment 1, with reference to Figure 1-4 , in embodiment 1, compression deformation test pressing speed V is 10mm / s,

[0035] A method for carrying out a thermal compression test with a thermal simulation testing machine, comprising the following steps:

[0036] 1) Configure the equipment conditions of Gleeble3500 thermal simulation testing machine, remove the coupler between the compression hammer head and the compression rod of the testing machine, and install the axial displacement sensor in the general unit of the testing machine;

[0037] 2) Measure the acceleration time. The test machine does not install the sample. Control the Gleeble3500 thermal simulation testing machine to compress the hammer head to perform the test of the no-load reduction speed. The displacement of 1s is designed to be 10mm, and the displacement value of the whole test is collected and drawn. figure 2 In the relationship curve between time and displacement shown, the time t=0.1s require...

Embodiment 2

[0042] Embodiment 2, with reference to figure 1 with Figure 5-7 , in embodiment 2, compression deformation test pressing speed V is 50mm / s,

[0043] A method for carrying out a thermal compression test with a thermal simulation testing machine, comprising the following steps:

[0044] 1) with the step 1) of embodiment 1);

[0045] 2) Measure the acceleration time, without installing the sample on the testing machine, control the compression hammer head of the Gleeble3500 thermal simulation testing machine to perform the test of the no-load compression speed, design the displacement of 1s to be 50mm, collect and obtain the displacement value of the whole test, and draw the attached Figure 5 In the relationship curve between time and displacement shown, the time t=0.08s required for the compression hammer head of the testing machine to reach the speed of 50mm / s is obtained by the tangent point method;

[0046] 3) According to the formula s=Vt / 2=50×0.08 / 2, the minimum accel...

Embodiment 3

[0050] Embodiment 3, with reference to figure 1 with Figure 8-10 , in embodiment 3, compression deformation test pressing speed V is 100mm / s,

[0051] A method for carrying out a thermal compression test with a thermal simulation testing machine, comprising the following steps:

[0052] 1) with the step 1) of embodiment 1);

[0053] 2) Measure the acceleration time, without installing the sample on the testing machine, control the Gleeble3500 thermal simulation testing machine to compress the hammer head to perform the test of no-load compression speed, design the displacement of 0.5s to be 50mm, collect and obtain the displacement value of the whole experiment, and draw the attached Figure 8 In the relationship curve between time and displacement shown, the time t=0.04s required for the compression hammer head of the testing machine to reach the speed of 100mm / s is obtained by the tangent point method;

[0054] 3) According to the formula s=Vt / 2=100×0.04 / 2, the minimum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com