A lamination optimization method for a composite material structure

A composite material and optimization method technology, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as simultaneous variable interaction, different scales of design variables, and a large number of design variables, etc., to reduce calculation time, Achieving versatility and reducing development time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

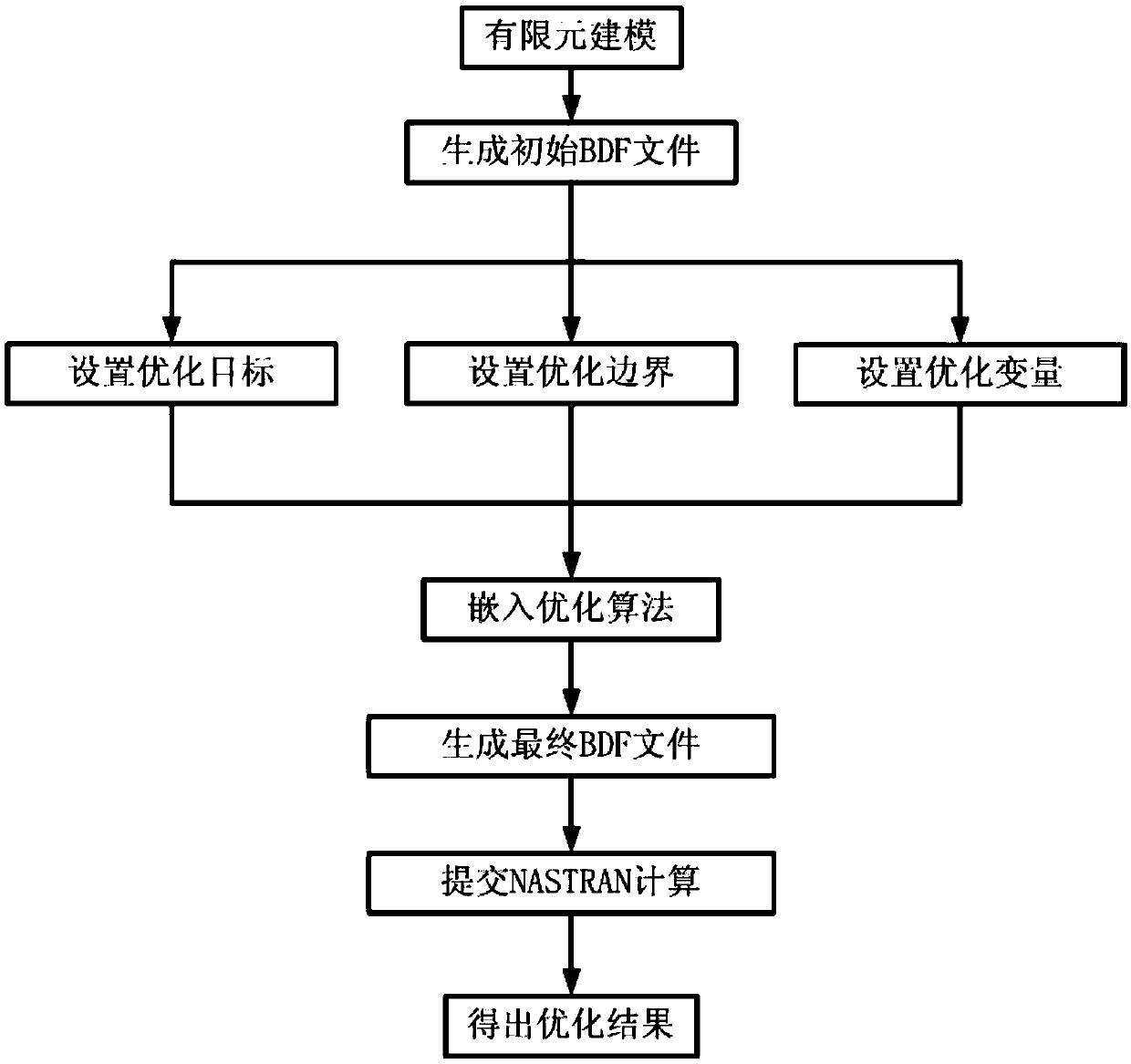

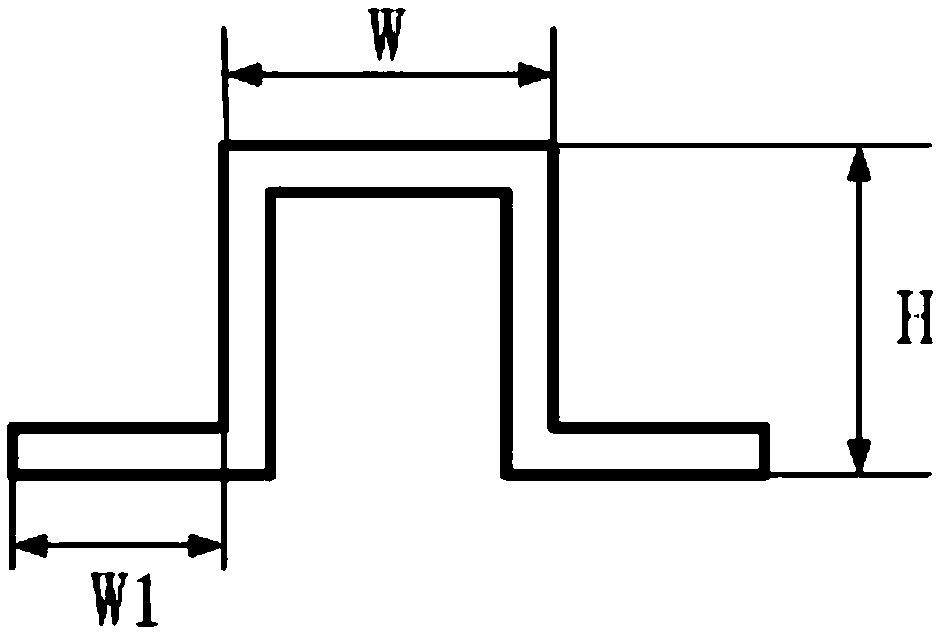

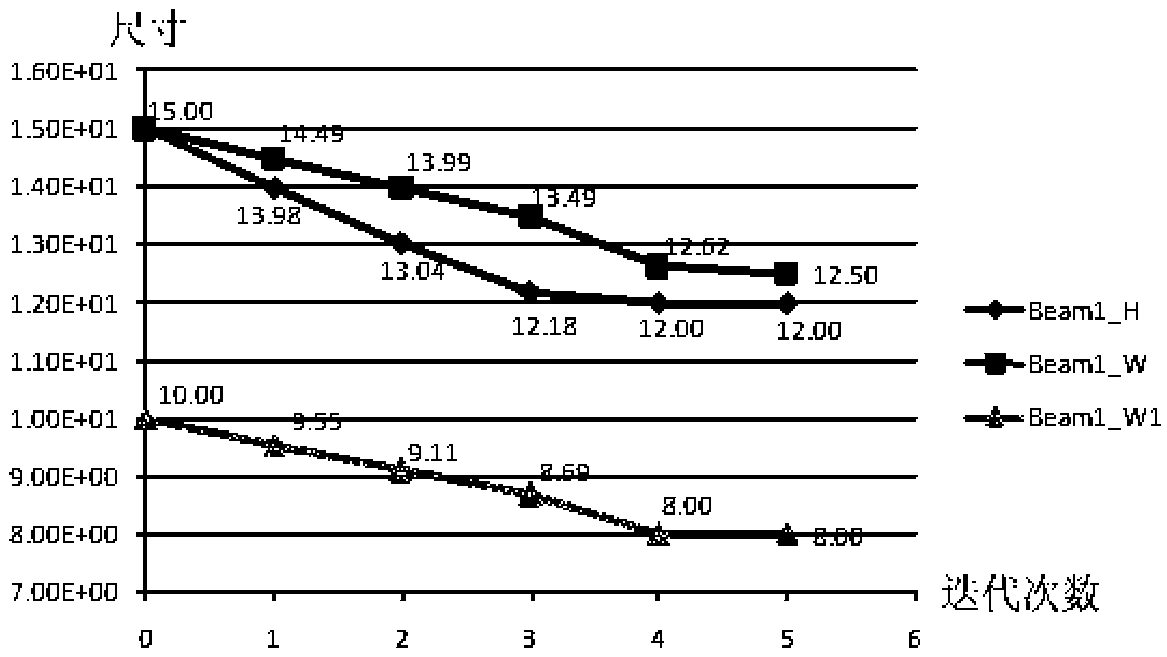

[0062] Such as figure 2 , to optimize the ply lay-up design of Beam1-Beam5 stringers, whose cross-section is π-shaped beam, and the optimization variables are W, H, W1 such as image 3 shown.

[0063] Material: T800H-6k-603A composite material fabric

[0064] Optimization method: gradient algorithm

[0065] Design variables: Beam sections W, H, W1 of Beam1-Beam5

[0066] Constraint response: 1mm

[0067] 1mm

[0068] 1mm

[0069] All beams are free from instability;

[0070] The maximum tensile and compressive strains of all elements are within the allowable range.

[0071] Optimization goal: the total mass is minimized.

[0072] Add the above optimization methods, optimization variables, responses, and optimization objectives into the BDF file for secondary development.

[0073] The BDF after secondary development is imported into Nastran for calculation, and it converges after 5 iterations. The optimization results are shown in Table 1.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com