Integrated self interlocking mechanism with brake breaking function

A locking mechanism, integrated technology, applied in the direction of electromagnetic relay details, relays, electrical components, etc., can solve the problems of high cost, small space, user loss, etc., to achieve high product reliability, simple and compact structure, overall structure concise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. However, the scope of protection of the present invention is not limited to the following examples, that is, any simple equivalent changes and modifications made based on the patent scope of the present invention and the content of the description are still within the scope of the patent of the present invention.

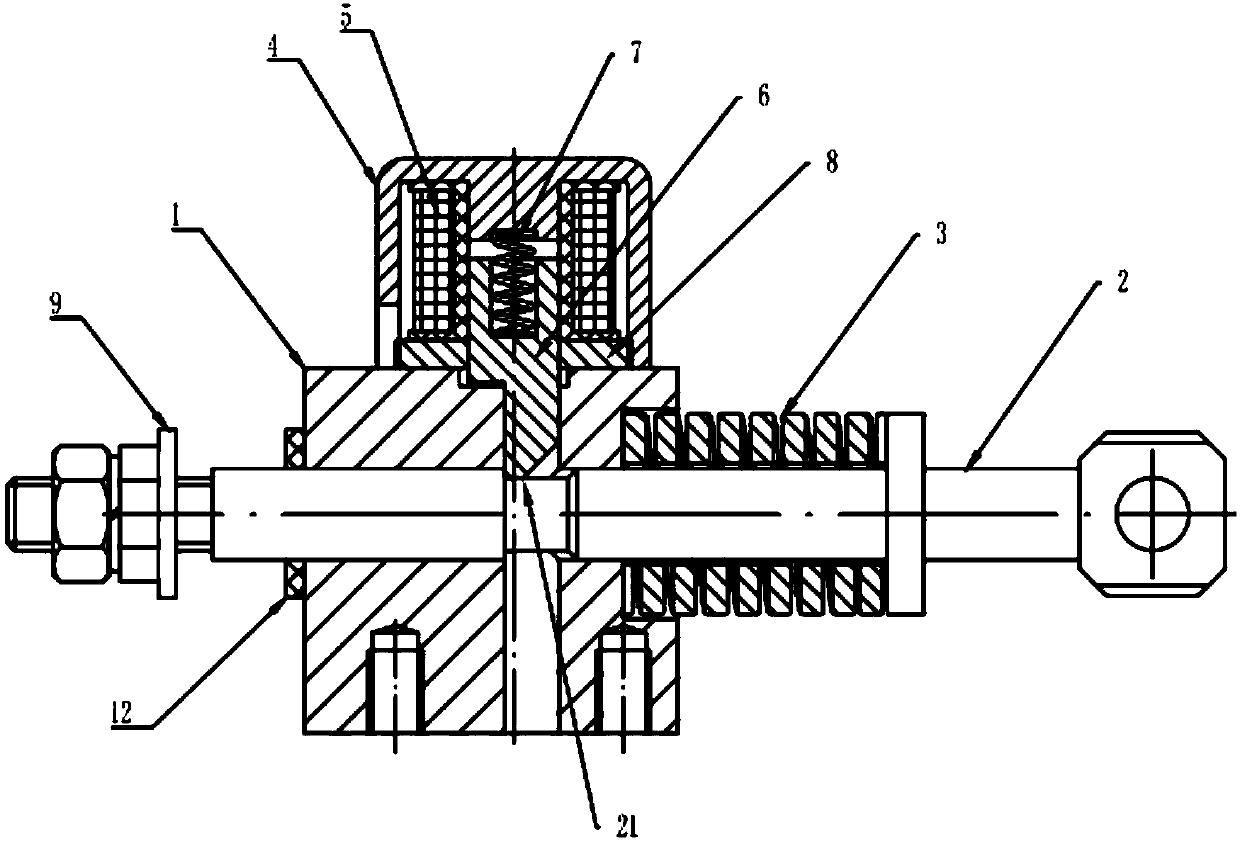

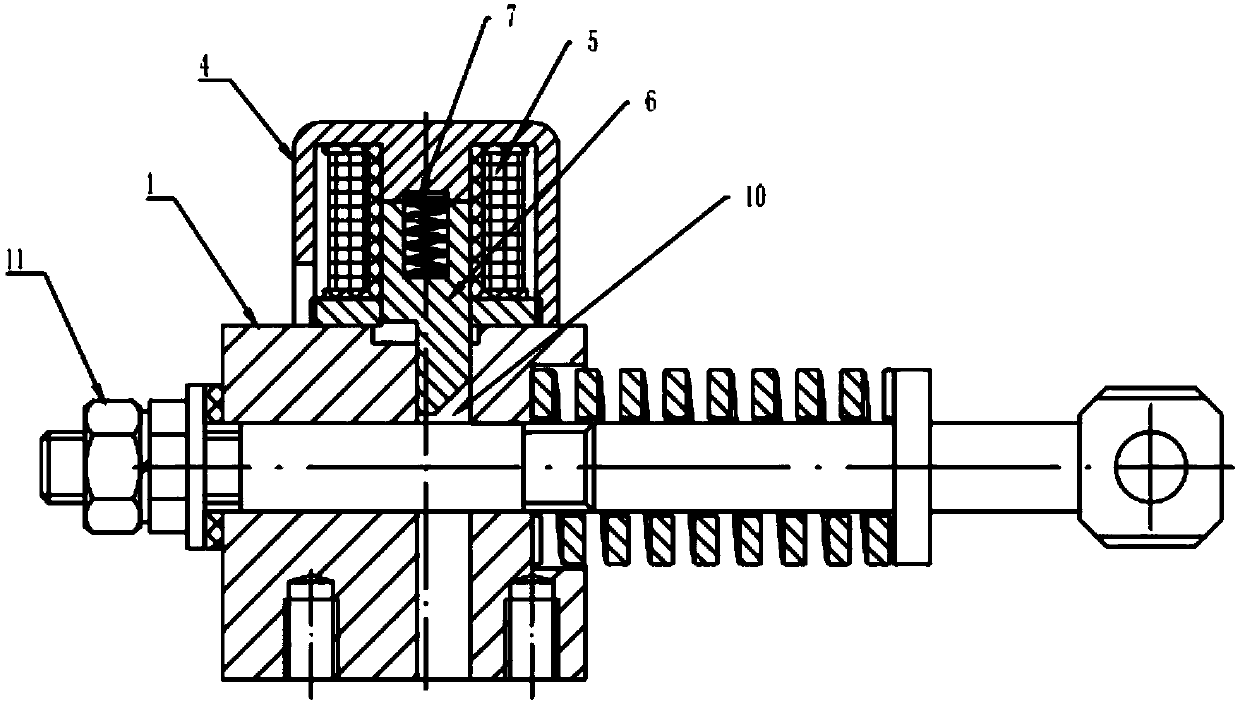

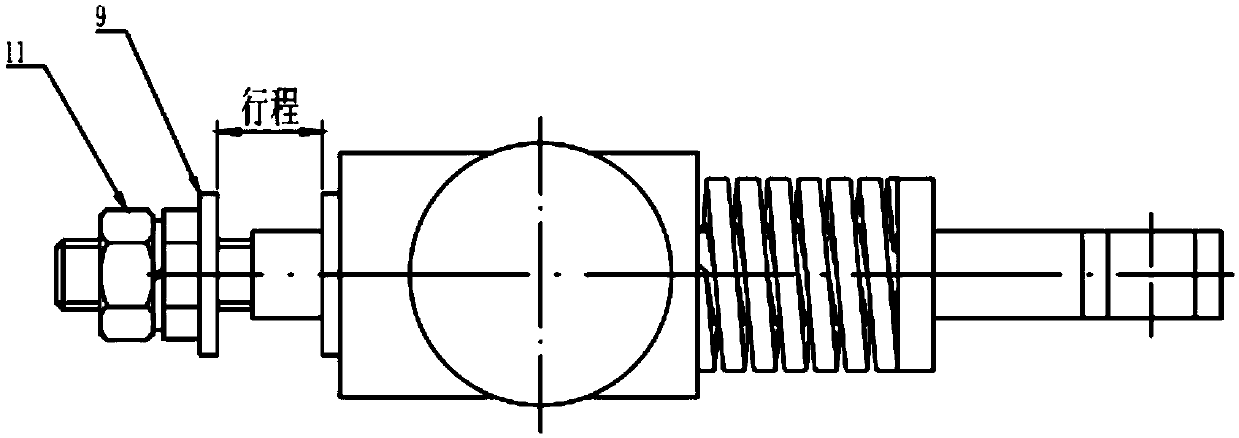

[0027] refer to Figure 1-3 , is an integrated self-locking mechanism with an opening function according to the present invention, including a base 1, a pull rod 2, an opening spring 3, a magnetic case 4, a tripping coil 5, a dead bolt 6, a return spring 7 and a yoke Iron 8.

[0028] The base 1 is provided with a longitudinal hole through the base along its longitudinal direction, and the middle part of the pull rod 2 is movably inserted in the longitudinal hole; the end of the pull rod 2 protruding from the base 1 is fixed with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com