Vehicle, and battery box, battery module, fire extinguishing component and fire extinguishing container thereof

A battery module and battery technology, applied in battery pack components, electrical components, circuits, etc., can solve problems such as cell explosion and battery cell pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 7

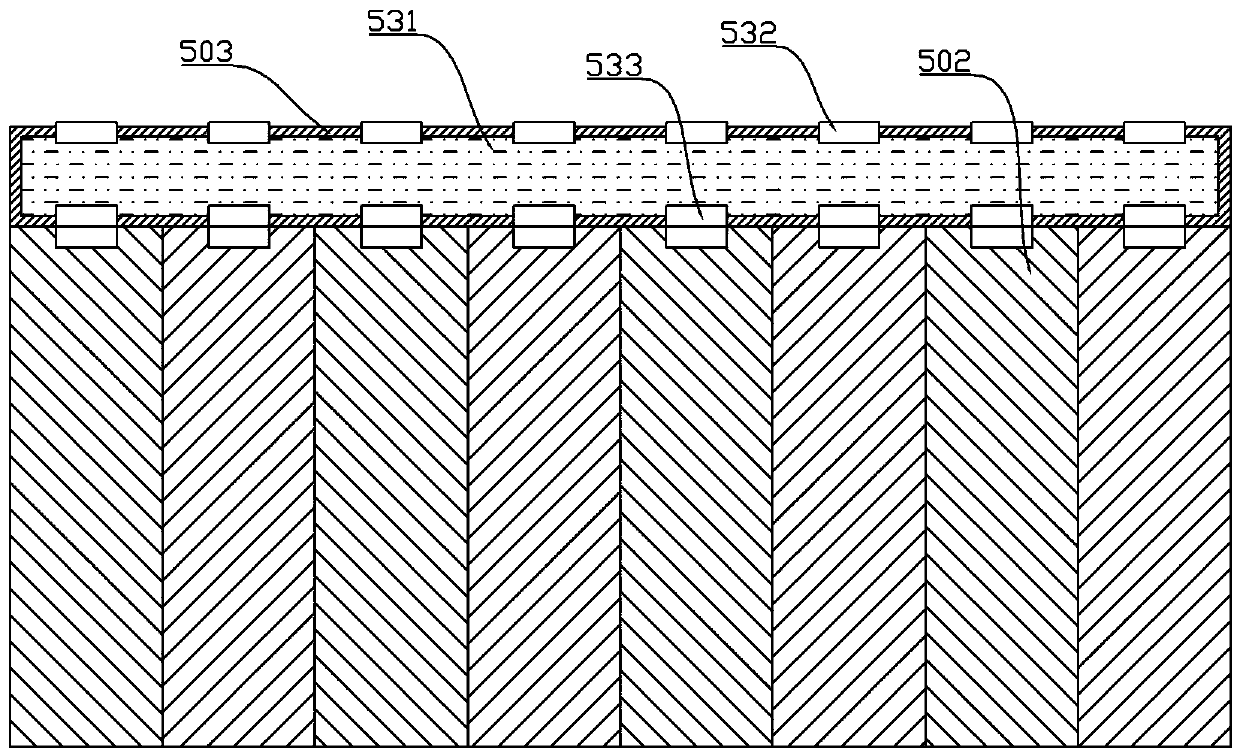

[0120] The specific embodiment 7 of the battery module of the present invention, the difference between the battery module in this embodiment and the battery module described in the above specific embodiment 6 of the battery module is only that: as Figure 13 As shown, there are two pairs of adjacent fire extinguishing agent containing chambers 731 on the shared cavity wall, which are provided with explosion-proof valves 7321 for the inner containing chambers, and the explosion-proof valves for the remaining containing chambers are explosion-proof valves 7322 for the external containing chambers.

[0121] The specific embodiment 8 of the battery module of the present invention, the difference between the battery module in this embodiment and the battery module described in the above specific embodiment 7 of the battery module is only that: as Figure 14 As shown, in this embodiment, two battery units share one fire extinguishing agent containing chamber 831, and two battery exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com