Self-lubricating pin contact

A pin contact and self-lubricating technology, applied in the direction of contact parts, can solve the problems of large insertion force and short insertion life, and achieve the goal of reducing insertion force, reducing insertion wear and improving insertion life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

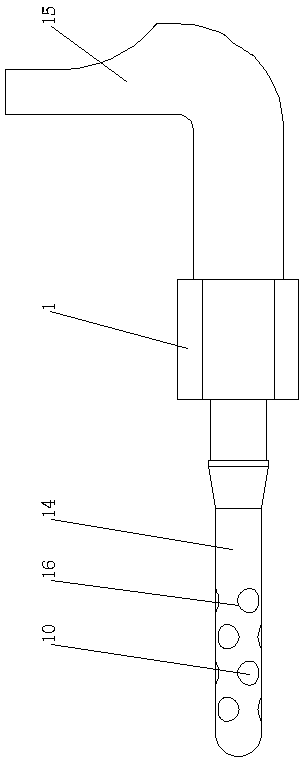

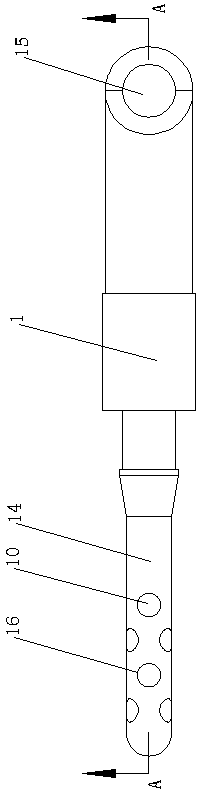

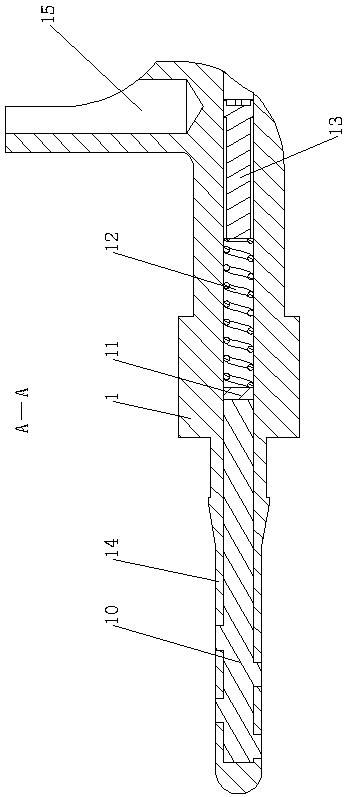

[0013] Specific implementation mode one: as Figure 1-Figure 3 As shown, this embodiment discloses a self-lubricating pin contact, including a pin contact body 1, and the self-lubricating pin contact also includes conductive grease 10 and a movable elastic limiter; the The pin contact body 1 is horizontally provided with a central hole from front to back, the central hole leads to the rear end of the pin contact body 1, the front end of the pin contact body 1 is closed, and the pin contact body 1 The front part is the plug-in end 14, and the side wall of the plug-in end 14 of the pin contact body 1 is provided with a plurality of holes 16 communicating with the center hole (preferably, the plurality of holes 16 are uniformly arranged on the plug-in On the side wall of the plug end 14 of the pin contact body 1), the center hole of the pin contact body 1 is located at the plug end 14 and filled with conductive grease 10, and the center hole of the pin contact body 1 is provided ...

specific Embodiment approach 2

[0014] Specific implementation mode two: as Figure 1-Figure 3 As shown, this embodiment is a further description of specific embodiment 1. The movable elastic limit device includes a piston 11, a piston spring 12 and a screw 13; the rear of the center hole of the pin contact body 1 There is a threaded hole at the end, the piston 11 is slidably arranged in the center hole of the pin contact body 1, and is in contact with the conductive grease 10, the screw 13 is screwed and connected with the threaded hole of the pin contact body 1, A piston spring 12 is arranged between the piston 11 and the screw 13 in the central hole of the pin contact body 1, and one end of the piston spring 12 is fixedly connected to the piston 11 (preferably, one end of the piston 11 and the piston spring 12 is welded as one).

specific Embodiment approach 3

[0015] Specific implementation mode three: as figure 1 , image 3 As shown, this embodiment is a further description of specific embodiment 1 or 2. The rear end of the pin contact body 1 is provided with a 90° bending end, and the 90° bending end is provided with a Pin solder cups 15 for wires (other termination methods, such as crimping, piercing, surface mount, fisheye, etc., can also be selected).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com