Meat grinder

A technology for a meat grinder and a driving motor, which is applied in the field of meat grinders, can solve the problems of clogging the propulsion screw and the like, and achieve the effect of easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is further described in detail by specific embodiments:

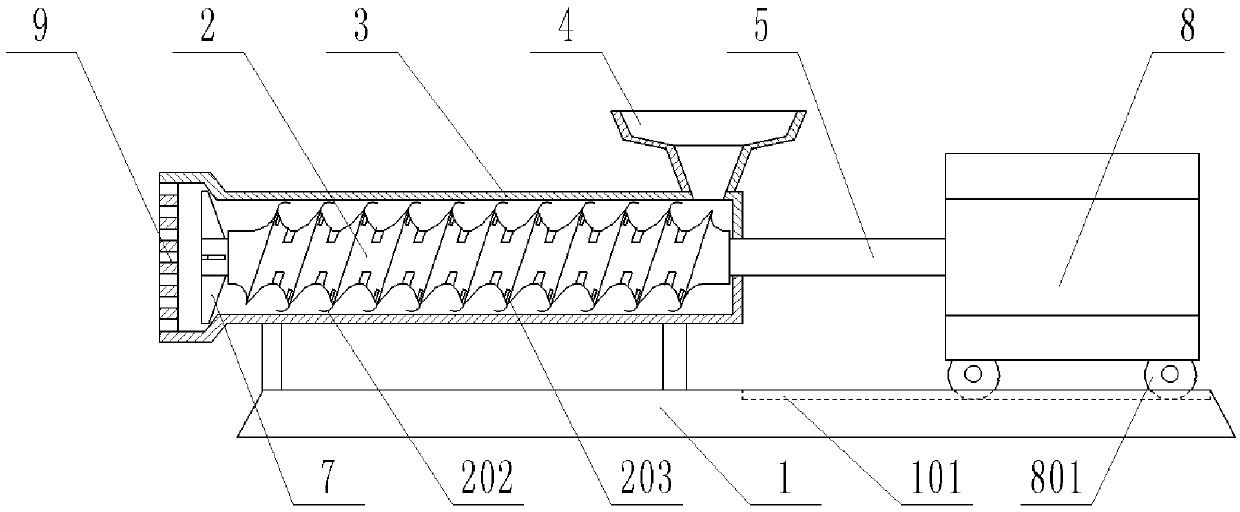

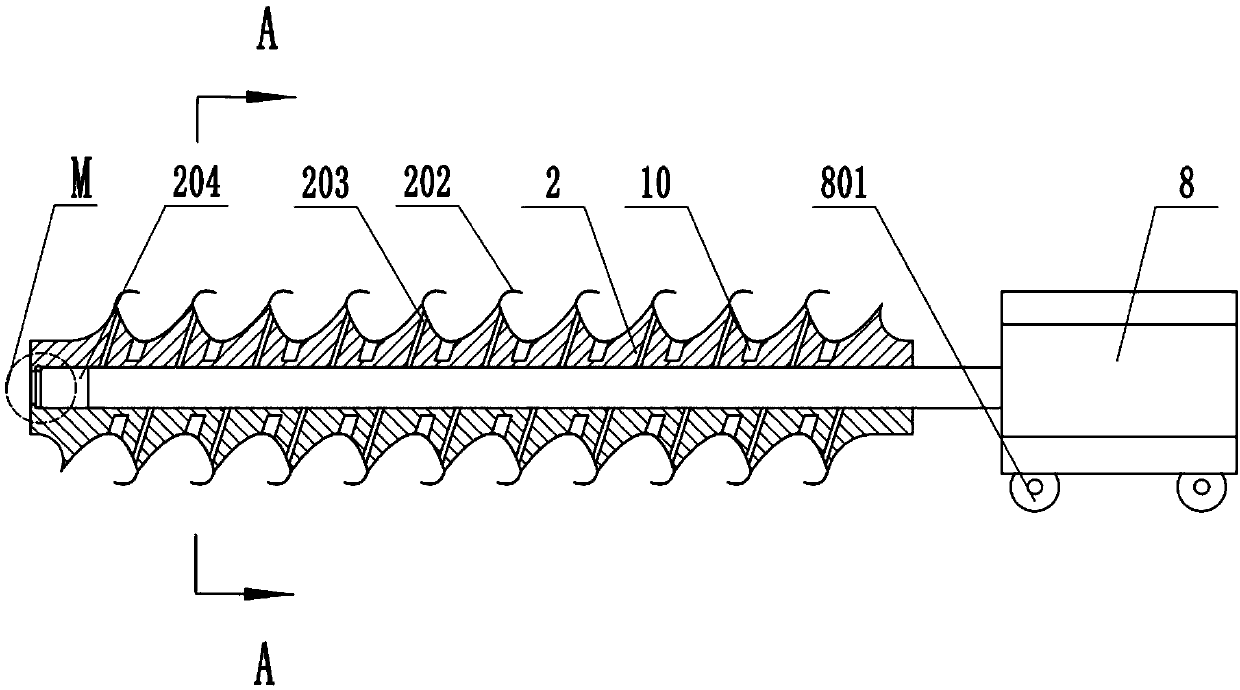

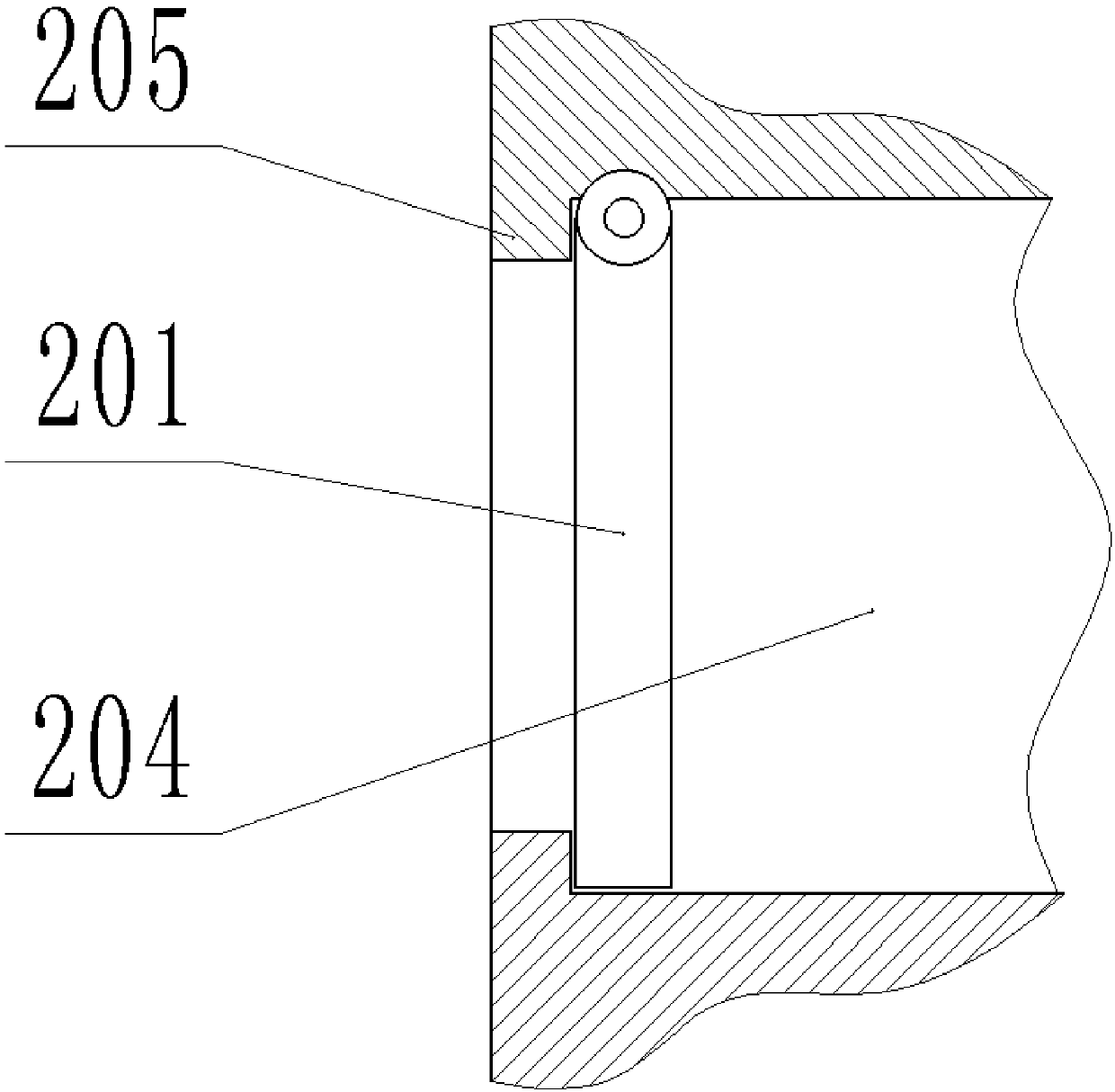

[0021] Reference numerals in the accompanying drawings include: base 1, guide groove 101, threaded rod 2, first baffle 201, second baffle 202, vent hole 203, threaded rod cavity 204, protrusion 205, housing 3, Feed nozzle 4, push rod 5, blade 6, cross knife 7, drive motor 8, traveling wheel 801, sieve plate 9, groove 10.

[0022] The example is basically as attached figure 1 Shown: a meat grinder, comprising a base 1, the top of the base 1 is fixedly connected to a cylindrical shell 3, and the axial direction of the shell 3 is parallel to the horizontal plane. The shell 3 is provided with a feeding mechanism, a feeding mechanism and a discharging mechanism in sequence.

[0023] The feeding mechanism includes a feeding nozzle 4, the top of the feeding nozzle 4 is flared, the bottom of the feeding nozzle 4 is fixedly connected to the shell wall of the casing 3, and the feeding nozzle 4 communicates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com