Preparation device of copper-clad plate and colloidal copper foil applied to preparation of copper-clad plate

A technology for a copper clad laminate and a preparation device is applied in the field of colloidal copper foil, which can solve the problems of low aging resistance, inability to greatly improve performance, poor high temperature and low temperature resistance, etc., and achieve the effect of preventing displacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

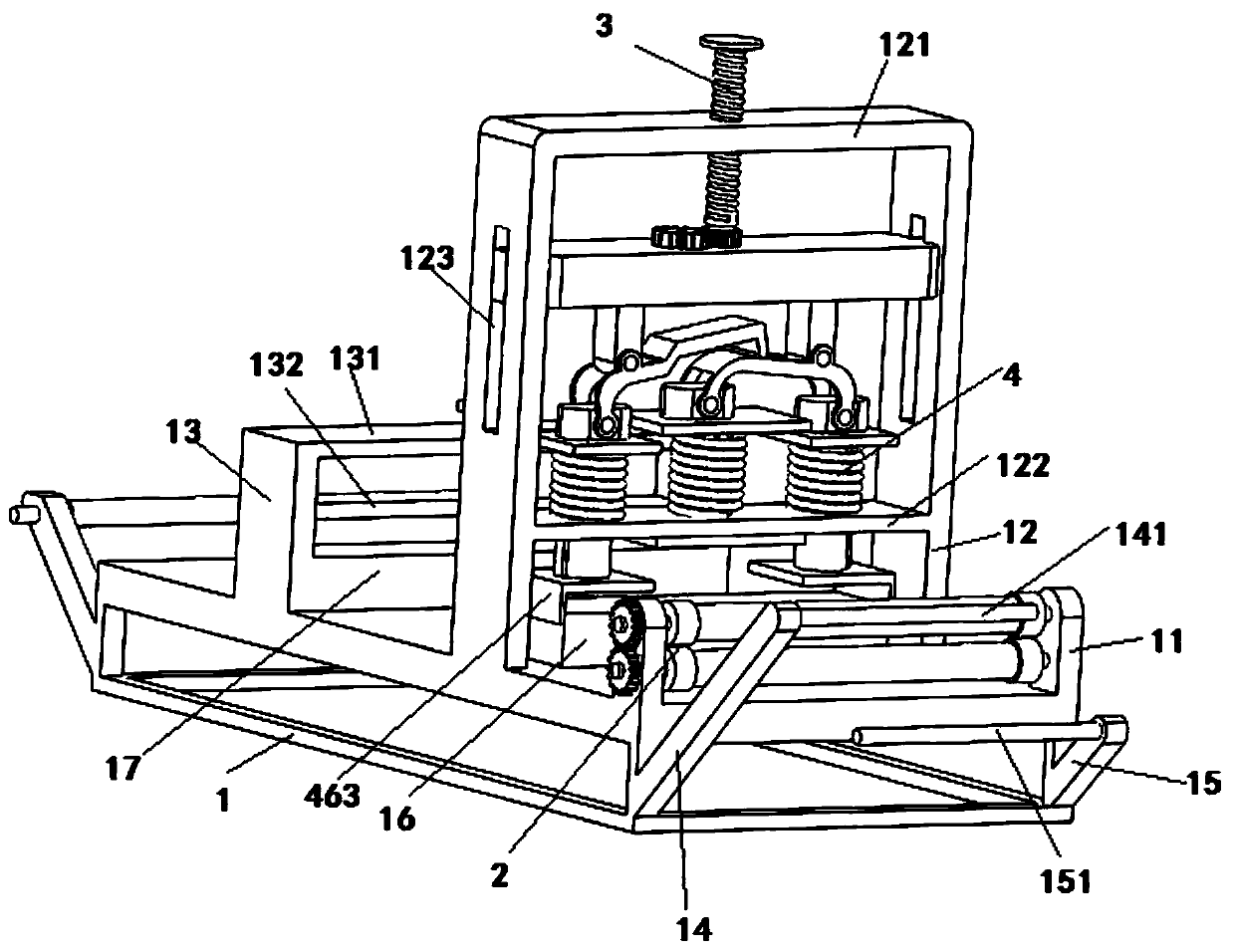

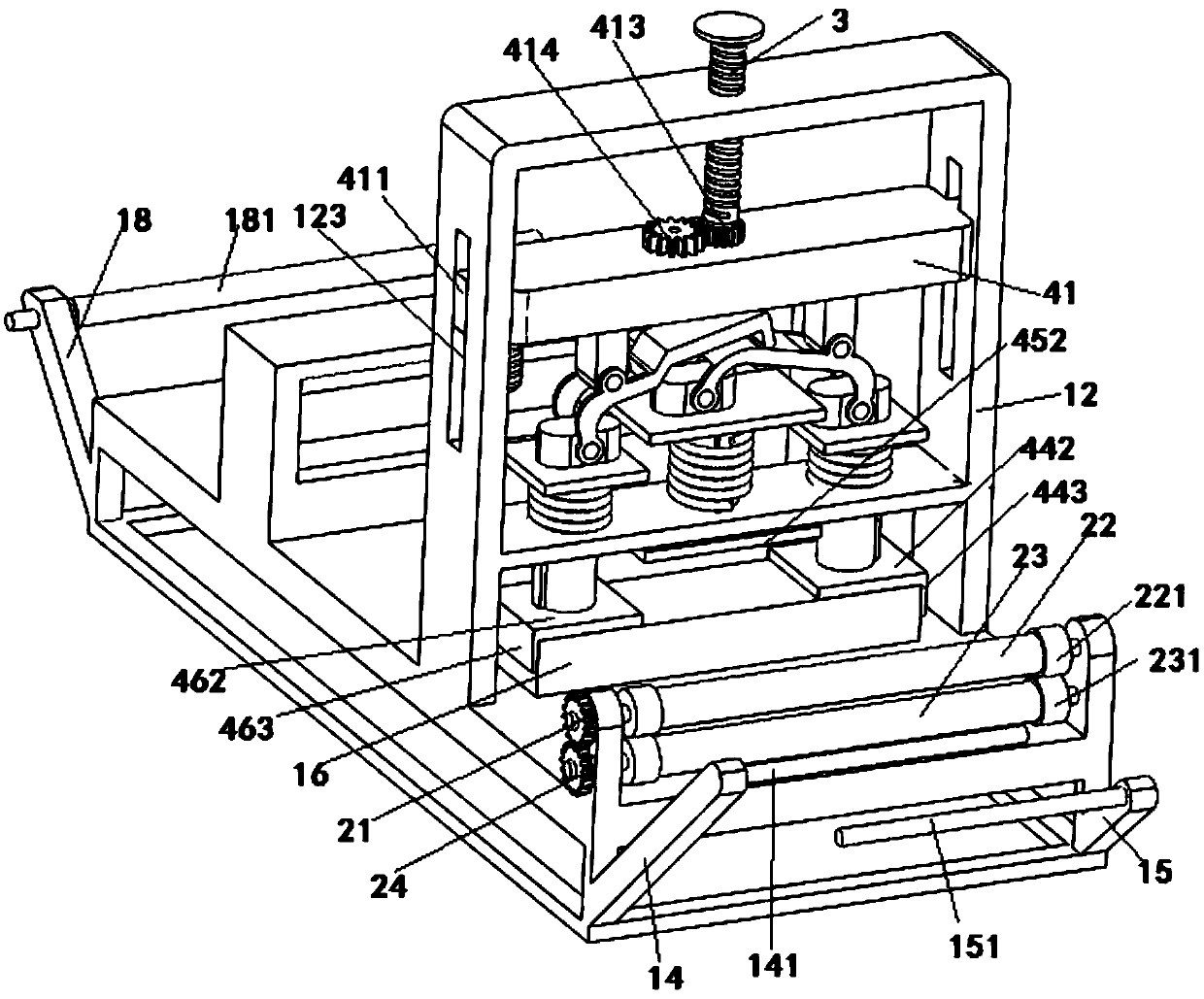

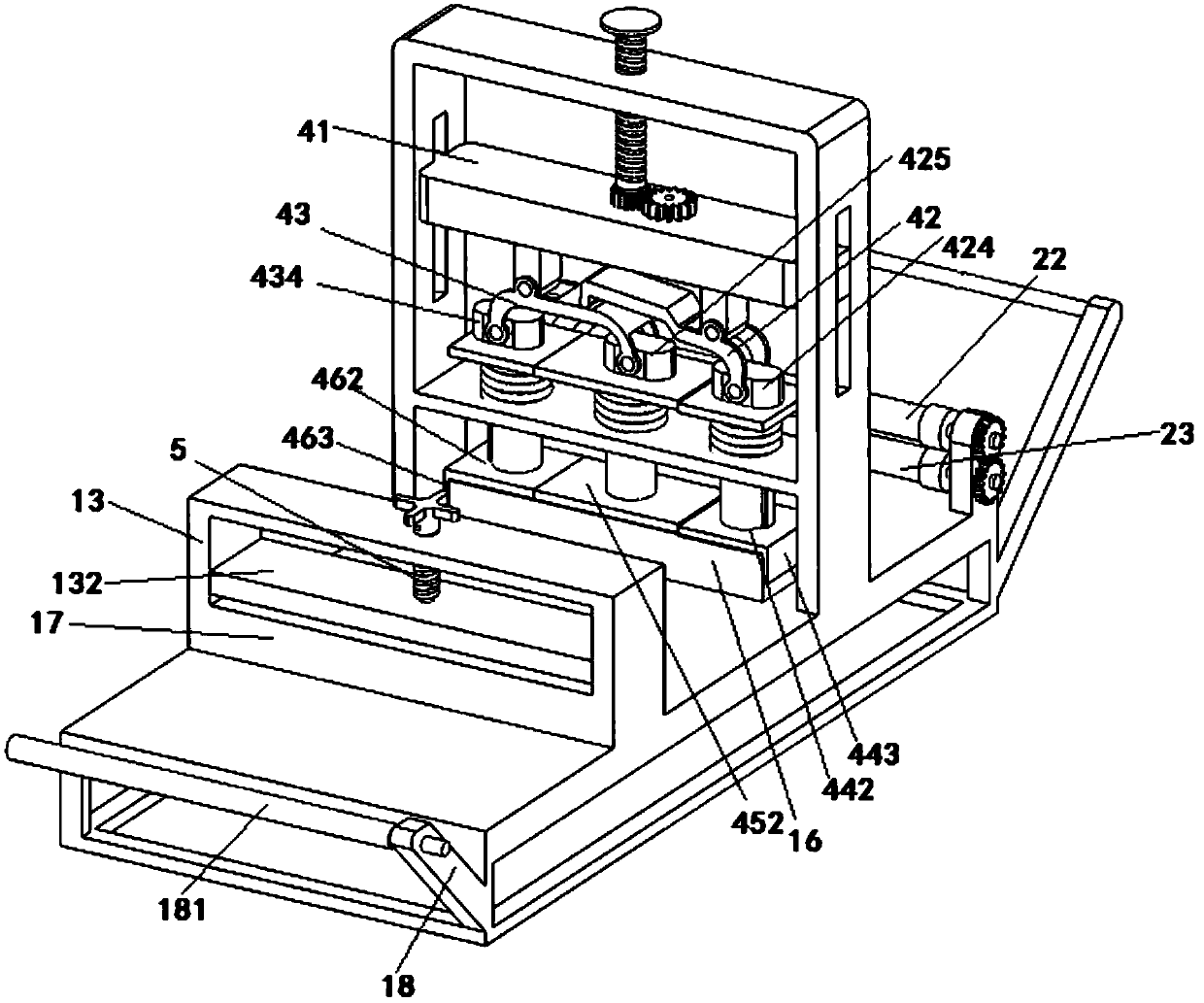

[0033] A preparation device for a copper clad board, through which the adhesive surface of the colloidal copper foil is pressed against the glass cloth to obtain a copper clad board, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the device includes a frame 1, and two oppositely arranged first support plates 11 are installed on one side of the surface of the frame 1, and a position adjustment mechanism 2 is installed and fixed between the two first support plates 11, while the frame 1, two opposite second support plates 12 are vertically installed and fixed on both sides of the middle part of the surface, a first top plate 121 is vertically connected and fixed between the tops of the two second support plates 12, and a bottom plate is vertically connected and fixed between the bottom ends of the two second support plates 12 122, the first adjustment screw 3 is installed on the first top plate 121, and the pressing mechanism 4 is installed and fixed between the...

Embodiment 2

[0047] Applied to the preparation of glue-coated copper foil for copper-clad boards, including electrolytic copper foil layer, the matte surface of electrolytic copper foil layer is coated with a layer of composite adhesive;

[0048] Wherein the specific preparation process of the composite binder is as follows:

[0049] In the first step, add 1kg of bisphenol A into N,N-dimethylformamide, stir and mix evenly, and then add 917g of 4-trifluoromethylbenzoyl chloride and 725g of p-cyanobenzoyl chloride to the reaction vessel. Stir the reaction for 10 hours, then evaporate and crystallize, wash with hot water at 50°C, and dry to obtain product A with a yield of 98.8%; introduce 4-trifluoromethylbenzoyl chloride into the reaction monomer through the acylation reaction of phenol and p-cyanobenzoyl chloride;

[0050] In the second step, add 1 kg of the product A prepared in the first step to nitrobenzene, heat up to 165 ° C, add 1.23 kg of anhydrous aluminum chloride to the reaction...

Embodiment 3

[0054] The specific preparation process of the composite binder is as follows:

[0055] In the first step, add 1kg of bisphenol A into N,N-dimethylformamide, stir and mix evenly, then add 1.45kg of p-cyanobenzoyl chloride into the reaction vessel, stir and react at room temperature for 10h, then evaporate and crystallize with After washing with hot water at 50°C, drying to obtain product A with a yield of 95.6%;

[0056] In the second step, add 1 kg of the product A prepared in the first step to nitrobenzene, heat up to 165 ° C, add 1.23 kg of anhydrous aluminum chloride to the reaction vessel, and react under constant temperature reflux for 20 hours, and then cool the reaction product to room temperature. Pour into a dilute hydrochloric acid solution with pH=1, filter after the solid precipitates out, and then wash and dry with ethanol to obtain product B with a yield of 93.1%;

[0057] In the third step, 1 kg of product B is added to 360 g of epichlorohydrin, and after the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com