Arm type torsional driving suspension frame

An active suspension, arm-type technology, applied in suspension, elastic suspension, transportation and packaging, etc., can solve the problems of difficult construction, lack of off-road capability for armaments, and difficulty in material transportation, achieving compact structure and improving obstacle clearance. capacity, the effect of improving space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

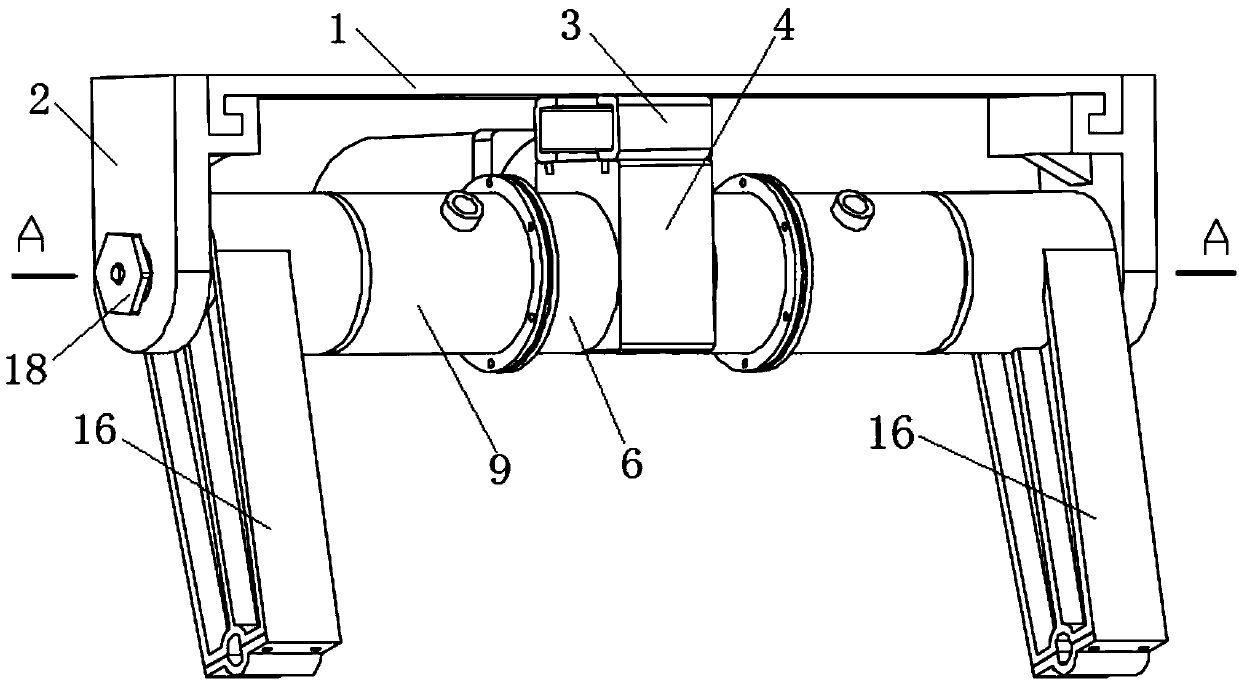

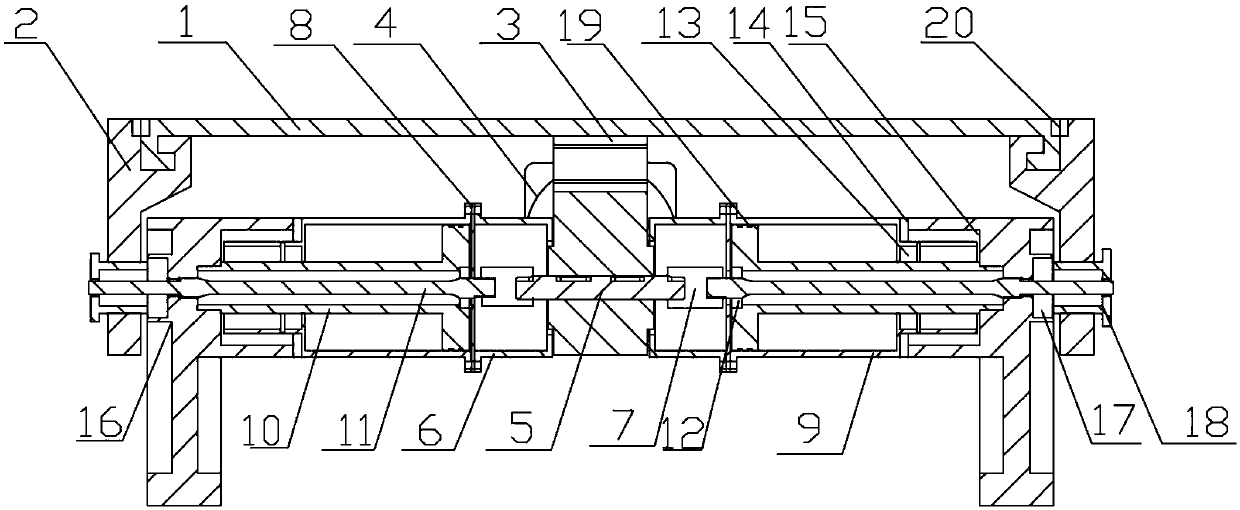

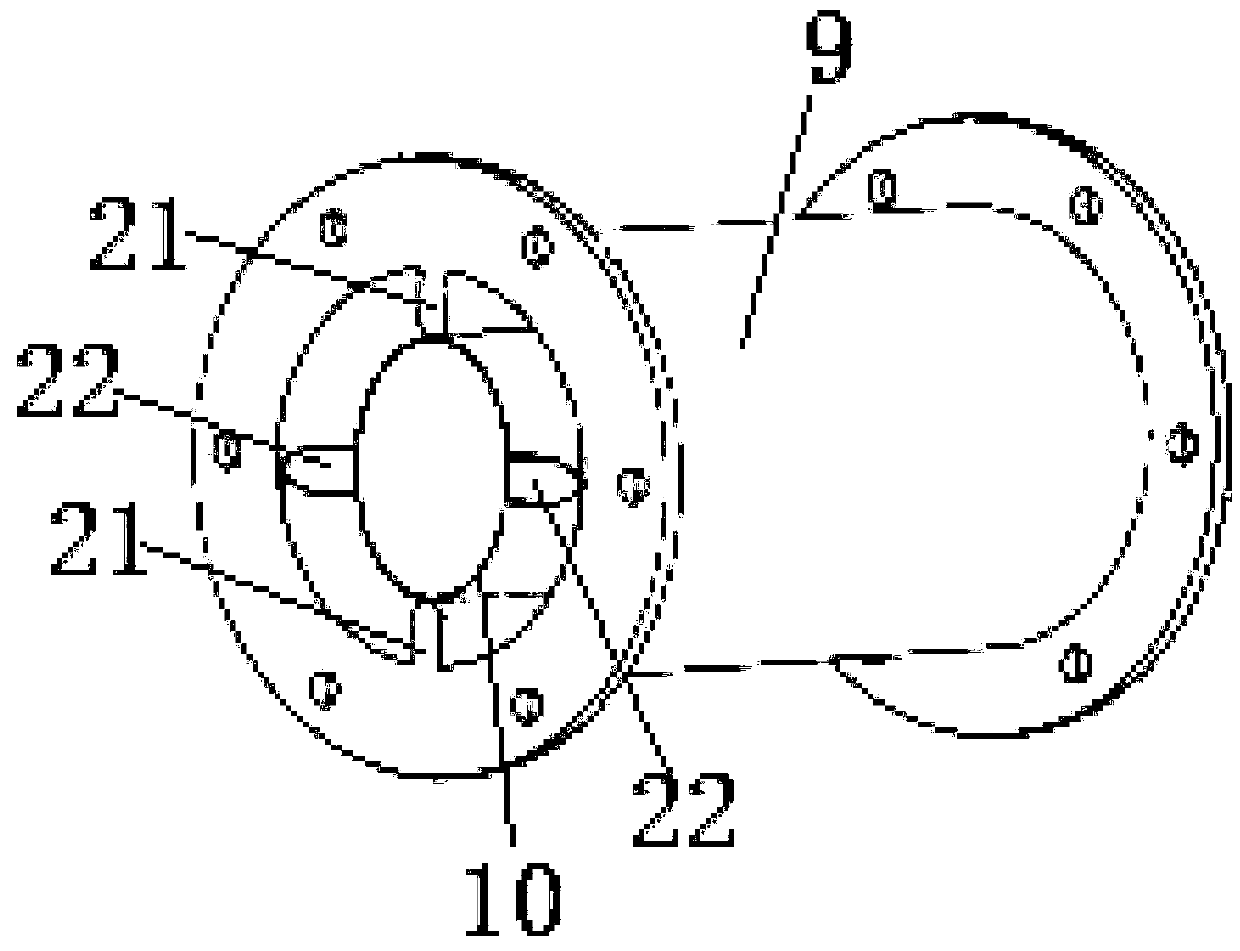

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0025] refer to Figure 1 ~ Figure 3 As shown, the arm type torsional active suspension in an embodiment provided by the present invention includes a reduction motor 4, two torsion bar springs 11, two trailing arms 16, two blade dampers and a vehicle frame, two The torsion bar springs 11 are distributed on both sides of the geared motor 4, the two output ends of the geared motor 4 are respectively connected to one end of the two torsion bar springs 11, and the other ends of the two torsion bar springs 11 are respectively connected to the two longitudinal arms 16 fixed, the two vane dampers are respectively sleeved on the two torsion bar springs 11, the two vane dampers are respectively connected and fixed with the two ends of the deceleration motor 4, the deceleration motor 4 is fixed on the vehicle frame, and the two torsion bar springs The outer en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com