Waterborne marine antifouling coating with low surface energy

A coating, silicon-modified acrylic technology, used in antifouling/underwater coatings, coatings, and biocide-containing paints, etc. problem, to achieve the effect of excellent antifouling effect, good mechanical properties and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

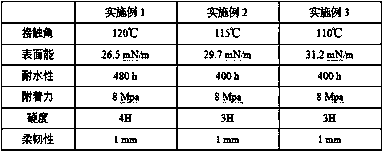

Embodiment 1

[0042] Example 1 A water-based low surface energy marine antifouling coating

[0043] 1. Preparation method

[0044] 1. Preparation of organofluorosilicon oligomers: Add 100 g of deionized water, 3 g of dodecylbenzenesulfonic acid, and 2 g of sodium dodecyl sulfate into a 500 mL four-necked flask, stir well and then heat up To 50 ℃ to fully dissolve, then add 5g D 3 F (trifluoropropylmethylcyclotrisiloxane), 25g D 4 (Octamethylcyclotetrasiloxane) was reacted at 50°C for 1 h, then raised to 75°C, reacted for 10 h, neutralized with glacial acetic acid to pH = 7, and stopped the reaction to obtain an organofluorine-silicon oligomer microemulsion.

[0045] 2. Preparation of organofluorosilicon-modified acrylic resin: Add 500 g of water and 8 g of emulsifier sodium lauryl sulfate into the reactor, heat to 60° C., and fully stir to dissolve. In another flask, pre-mix 200 g methyl methacrylate, 150 g butyl acrylate, and 70 g α-methacrylic acid, take out 1 / 10 of the acrylate monome...

Embodiment 2

[0047] Example 2 A water-based low surface energy marine antifouling coating

[0048] 1. Preparation method

[0049] 1. Preparation of organofluorosilicon oligomers: Add 110 g of deionized water, 3 g of dodecylbenzenesulfonic acid, and 3 g of sodium dodecyl sulfate into a 500 mL four-necked flask, stir well and heat up to 50°C to fully dissolve, then add 4g D 3 F (trifluoropropylmethylcyclotrisiloxane), 25g D 4 (Octamethylcyclotetrasiloxane) was reacted at 50°C for 1 h, then raised to 75°C, reacted for 10 h, neutralized with glacial acetic acid to pH=7, and then stopped the reaction to obtain organofluorine-silicon oligomer microemulsion .

[0050] 2. Preparation of organofluorosilicon-modified acrylic resin: Add 500 g of water and 10 g of emulsifier sodium lauryl sulfate into the reactor, heat to 60° C., and fully stir to dissolve. In another flask, pre-mix 210 g methyl methacrylate, 160 g butyl acrylate, and 80 g α-methacrylic acid, take out 1 / 10 of the acrylate monomer ...

Embodiment 3

[0052] Example 3 A water-based low surface energy marine antifouling coating

[0053] 1. Preparation method

[0054] 1. Preparation of organofluorosilicon oligomers: Add 80 g of deionized water, 2 g of dodecylbenzenesulfonic acid, and 2 g of sodium dodecyl sulfate into a 500 mL four-necked flask, stir well and heat up to 50°C to fully dissolve, then add 4g D 3 F (trifluoropropylmethylcyclotrisiloxane), 25g D 4 (Octamethylcyclotetrasiloxane) was reacted at 50°C for 1 h, then heated to 75°C, reacted for 10 h, neutralized with glacial acetic acid to pH = 7, and then stopped the reaction to obtain an organofluorine-silicon oligomer microemulsion .

[0055] 2. Preparation of organofluorosilicon-modified acrylic resin: Add 500 g of water and 10 g of emulsifier sodium lauryl sulfate into the reactor, heat to 60° C., and fully stir to dissolve. In another flask, pre-mix 220 g methyl methacrylate, 170 g butyl acrylate, and 90 g α-methacrylic acid, take out 1 / 10 of the acrylate mono...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap