F-shaped reinforced concrete trunk pipe jacking

A technology for reinforced concrete and pipe jacking, which is applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc. It can solve problems such as difficult to push, difficult to push forward construction, and high friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

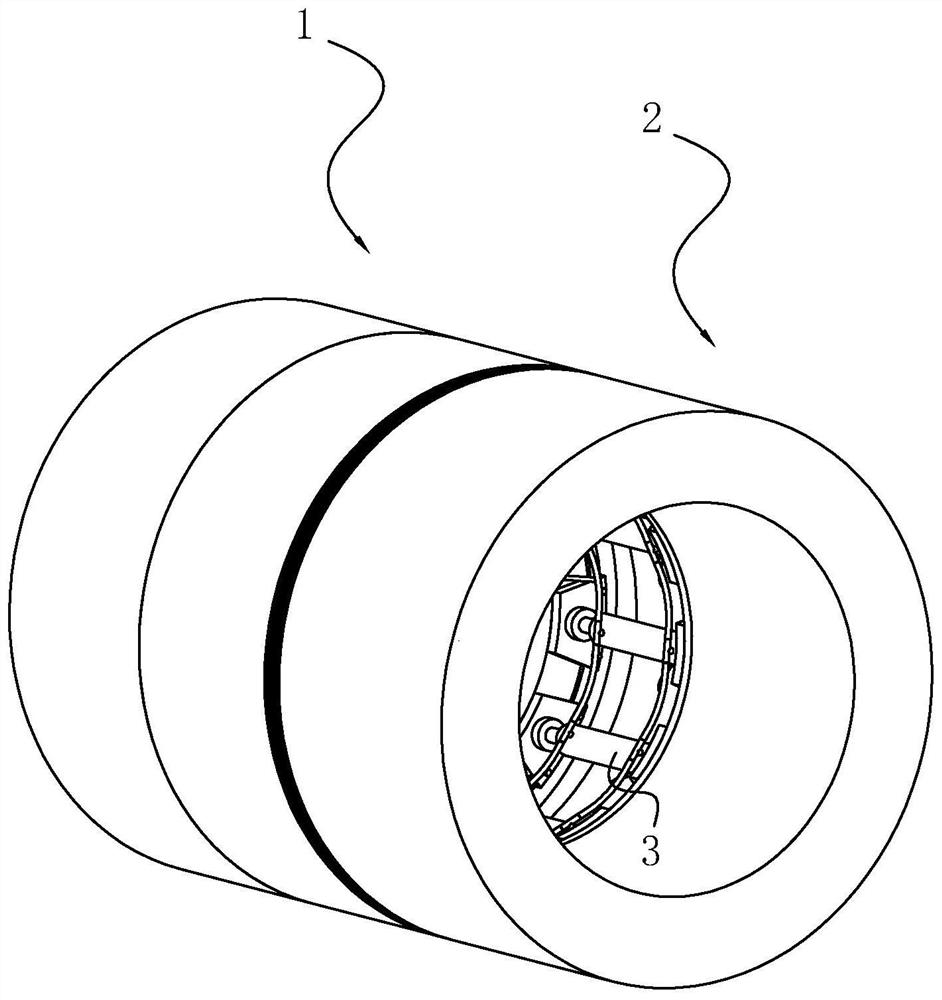

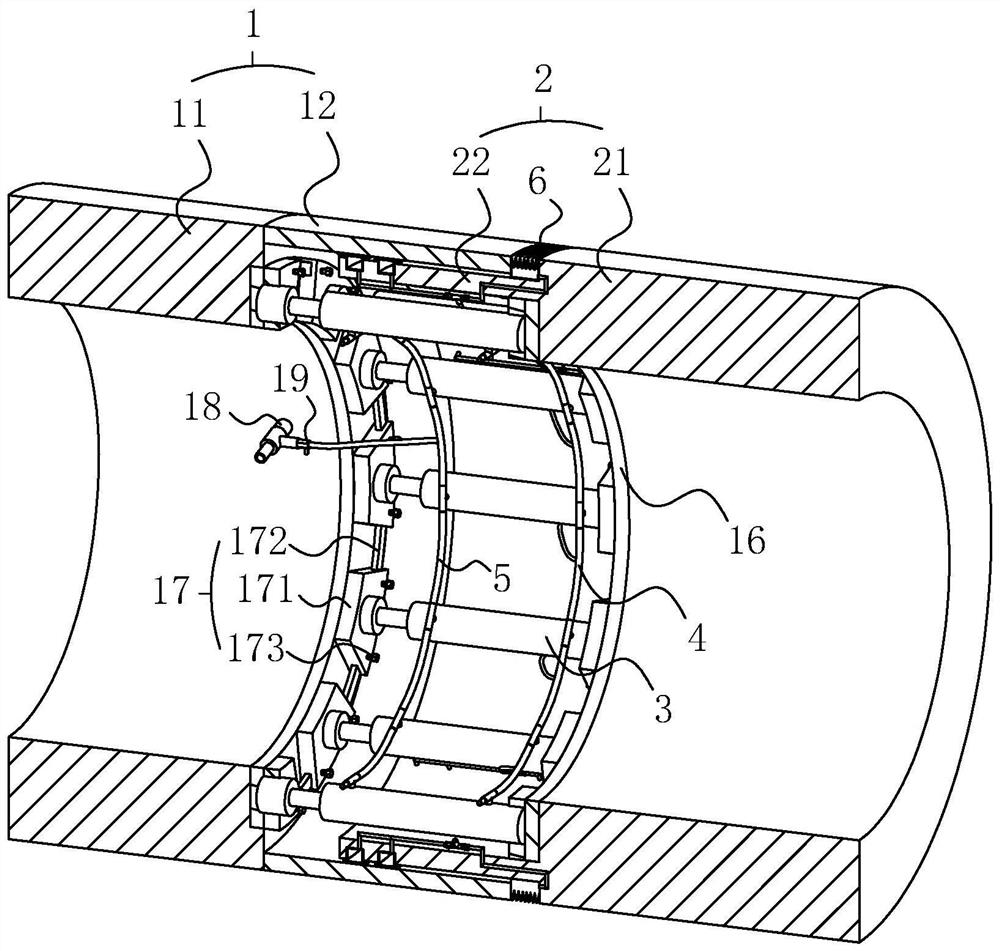

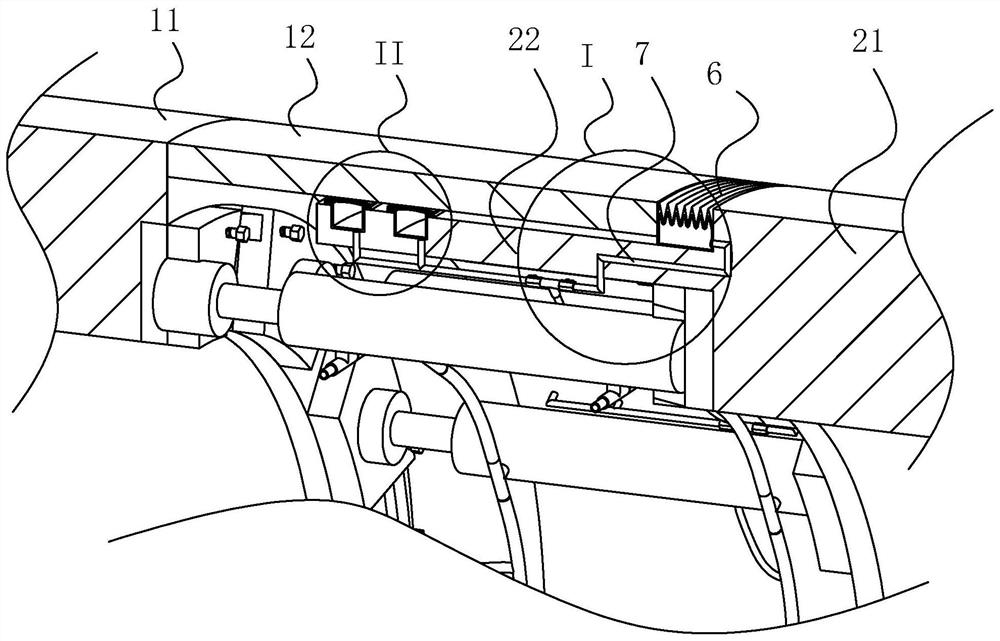

[0035] A kind of F-type reinforced concrete trunk pipe jacking, refer to figure 1 As shown, it includes a front shell 1 and a rear shell 2 coaxially arranged, the front shell 1 is plugged with the front top pipe, the rear shell 2 is socketed with the rear top pipe, and the front shell A plurality of hydraulic cylinders 3 are arranged between the body 1 and the rear shell 2. During the construction process, a relay pipe jacking is provided at intervals of multiple jacking pipes, so that after the long-distance laying of the jacking pipes, the front shell 1 The hydraulic cylinder 3 between it and the rear shell 2 pushes the front jacking pipe forward, and then the external jacking cylinder pushes the rear jacking pipe forward, thereby resetting the hydraulic cylinder 3, thereby avoiding After the long-distance jacking pipe is laid, it is difficult to push the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com