A dynamic production scheduling system and production scheduling method for a composite material workshop

A production system and production scheduling technology, applied in the field of automated manufacturing, can solve the problems of unclear production scheduling practice guidance in composite workshops, and no dynamic production scheduling system has been formed, so as to achieve good adaptability, improve adaptability, and improve real-time performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

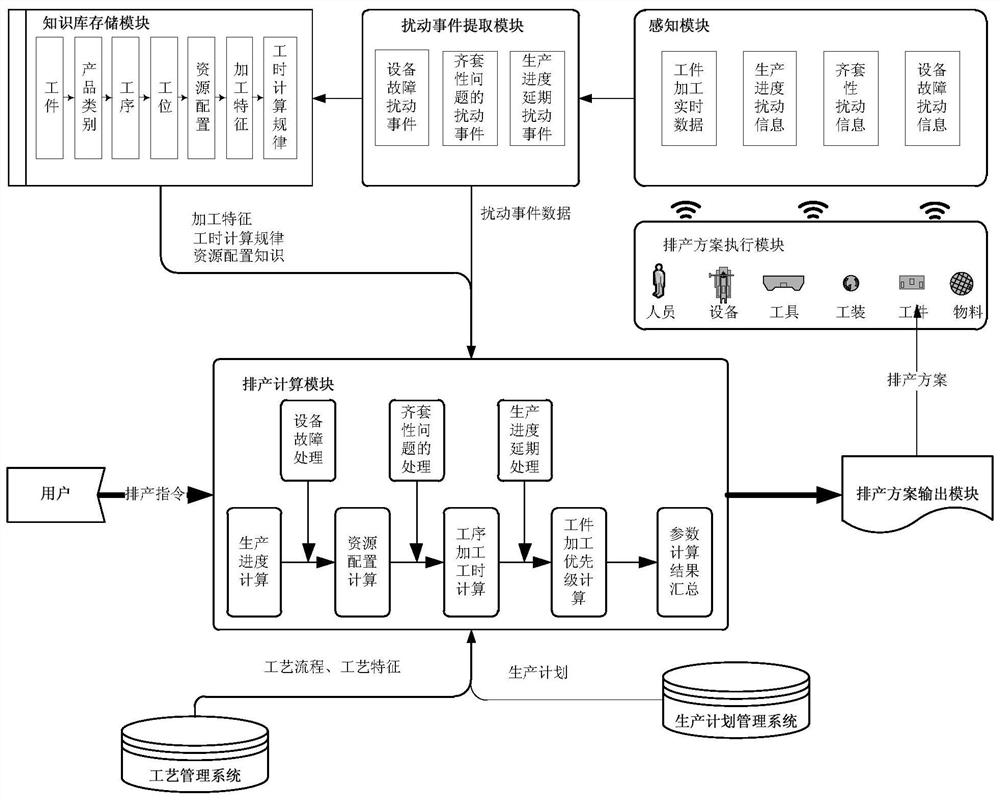

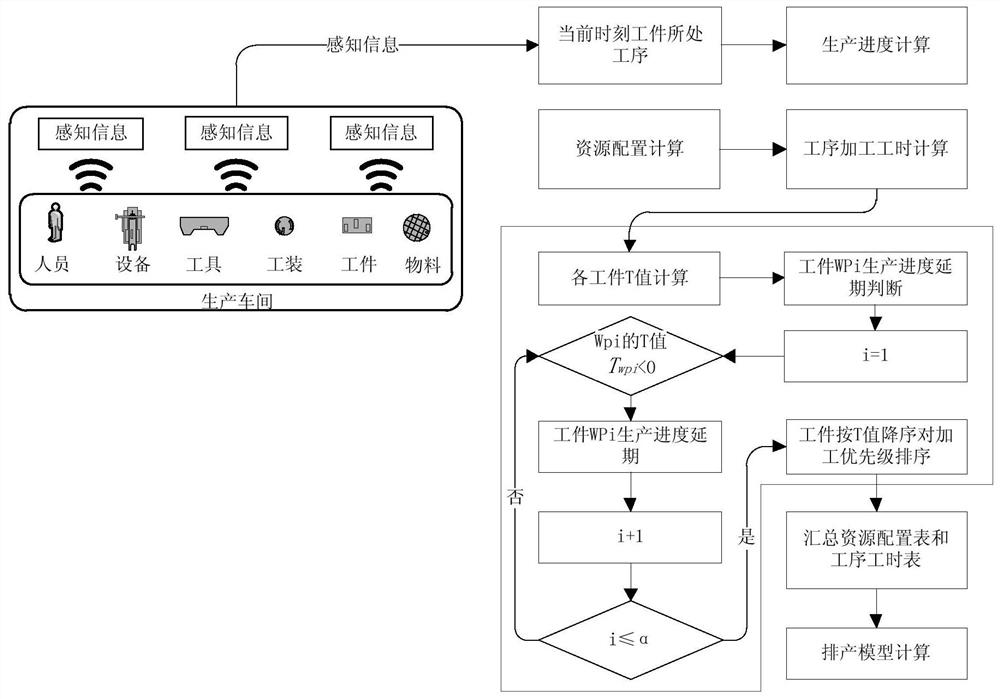

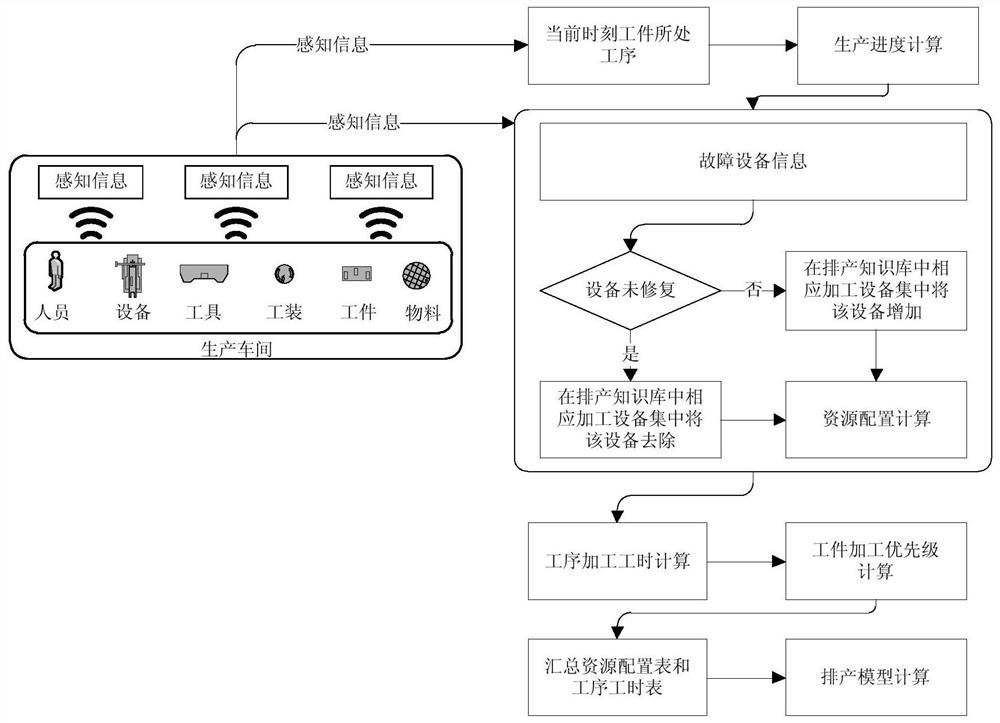

[0058] The technical solution of the present invention is: with the help of the composite material workshop IOT system, construct a dynamic production scheduling business model and calculation model based on perceptual information, intelligently match manufacturing resources and processes according to the production plan and the actual operating status of the workshop, and calculate and generate the workshop Based on the current man-hours of all parts in the processing process, the process to be processed and the man-hours, etc., the dynamic production scheduling based on the workshop perception information is realized through the genetic algorithm, and the production scheduling plan is generated and output.

[0059] The invention provides a dynamic production scheduling system for a composite material workshop, combining...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com