Insulation rod

A technology of insulating rods and working rods, which is applied in the direction of overhead lines/cable equipment, switchgear, electrical components, etc., can solve the problems of insufficient length of insulating rods, and achieve the effects of improving operating efficiency, simple structure, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

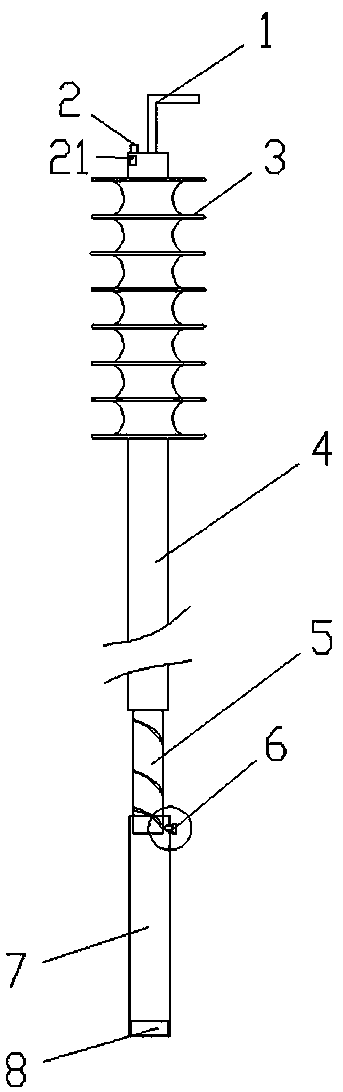

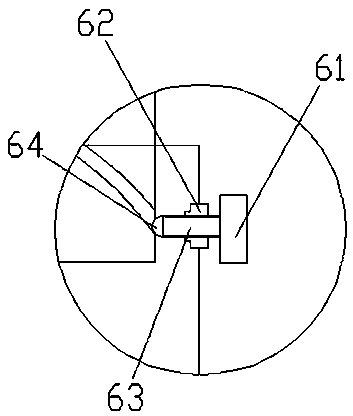

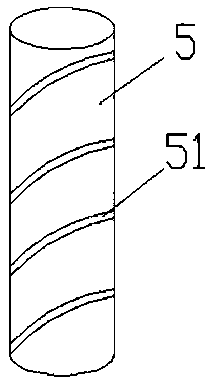

[0019] as attached Figures 1 to 4 As shown, a kind of insulating rod, comprises working rod 4 and hand-held rod 7,: described working rod 4 top is provided with working head 1, is provided with insulator 3 at the upper end of working rod 4, and described working rod 4 bottoms and rotating rod 5 is fixedly connected, the outer surface of the rotating rod 5 is provided with a surrounding groove 51, the interior of the handle rod 7 is hollow, the rotating rod 5 is installed inside the handle rod 7, and a long moving chute 71 is provided on the outer surface of the handle rod 7, A moving device 6 is arranged in the chute 71, and the moving device 6 can drive the rotating rod 5 to move up and down along the track of the groove 51.

[0020] Working process of the present invention is as follows:

[0021] Adjust the length of the insulating rod, the outer surface of the rotating rod 5 is provided with a surrounding groove 51, the rotating rod 5 is fixedly connected with the working...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com