Capillary electronic cigarette atomizer

An electronic cigarette atomizer and capillary tube technology, applied in tobacco, smoker's products, applications, etc., can solve the problems of easy oil leakage heating wire, dry burning, etc., to reduce the risk of oil leakage, uniform atomization, and contact area. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the examples and accompanying drawings, and the examples are only for illustrating the present invention, rather than limiting the present invention.

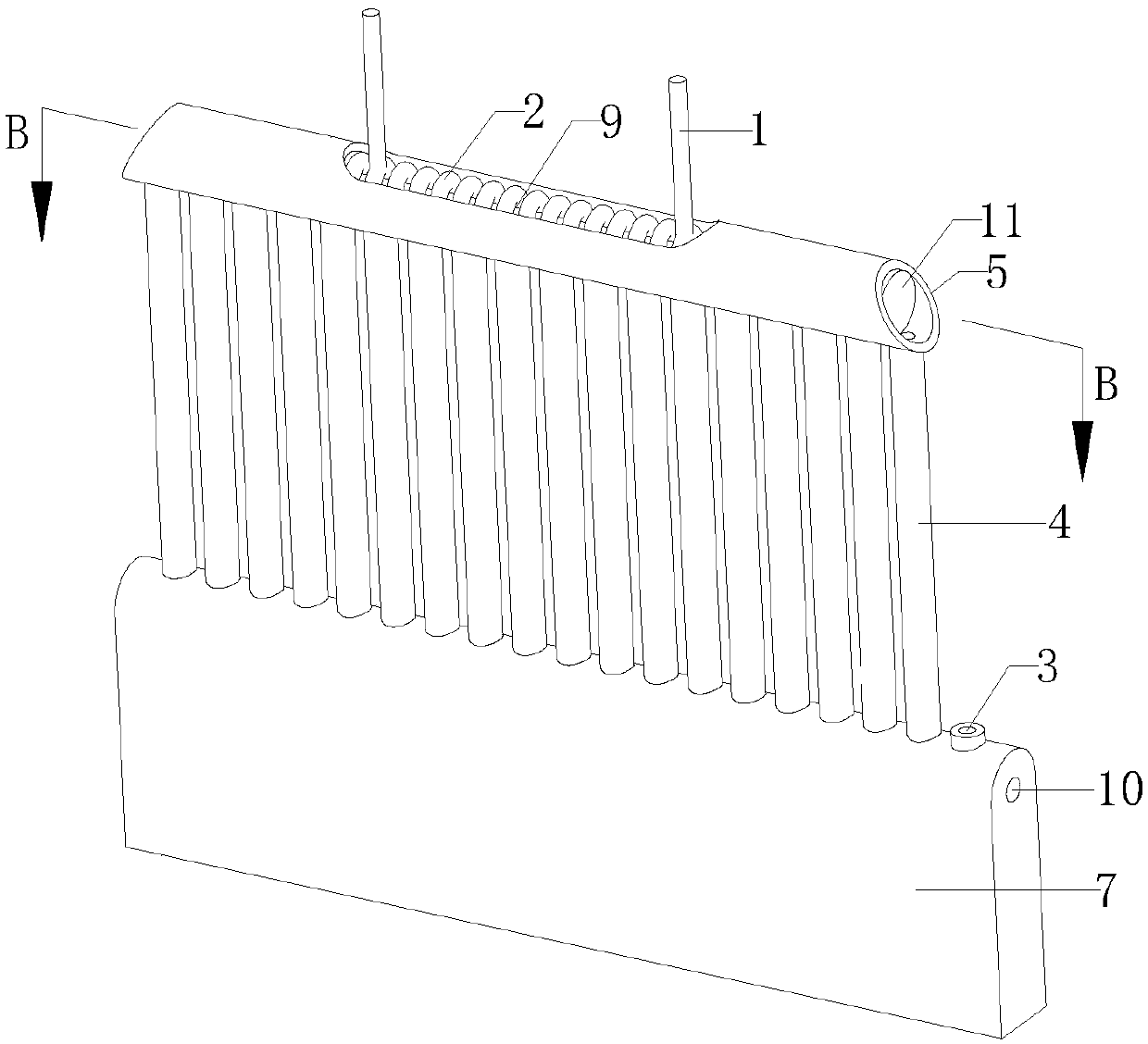

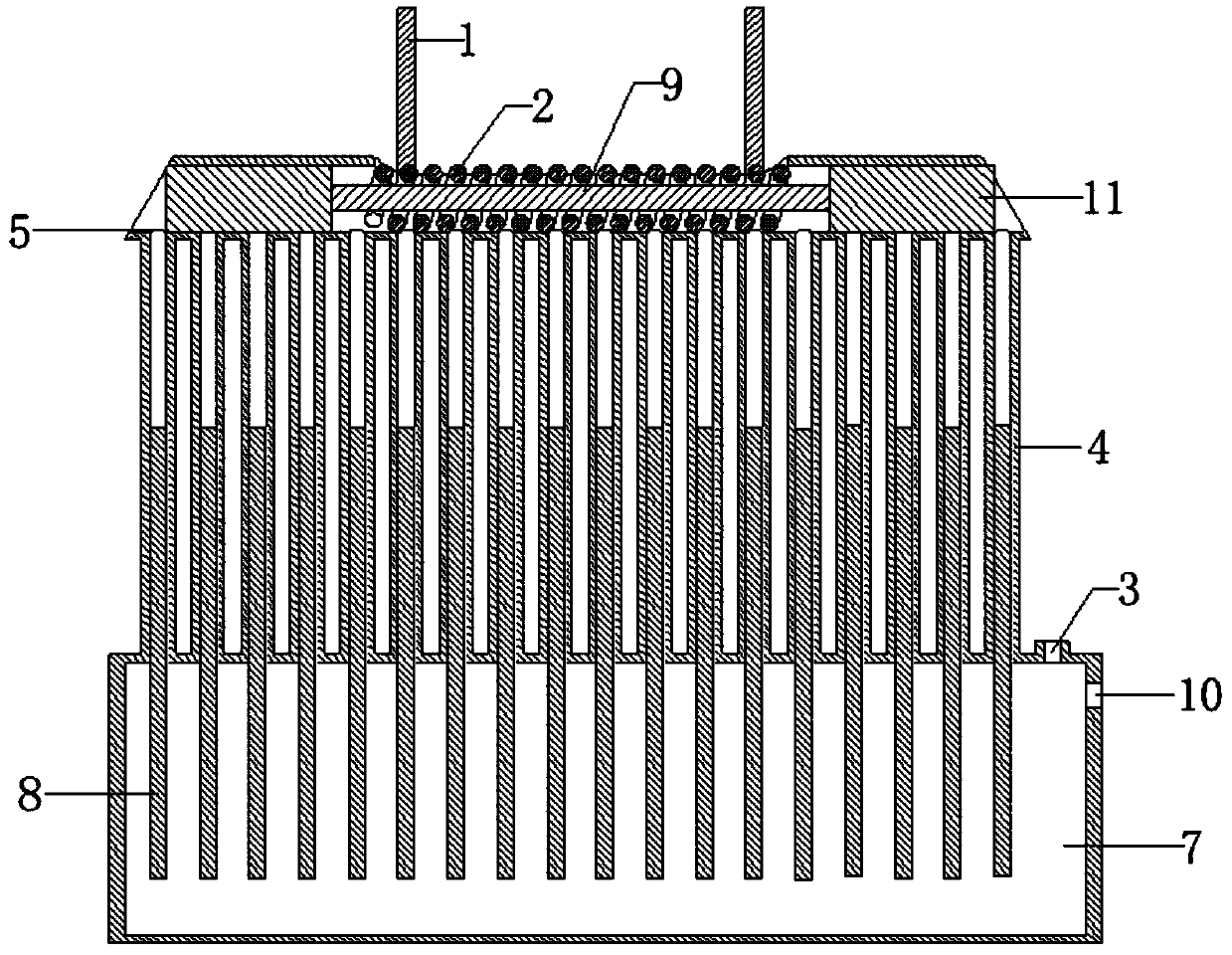

[0025] The capillary tube electronic cigarette atomizer of the present invention comprises the following components:

[0026] The outer wall of the oil storage bottle 7 is provided with a capillary conduit 4 that penetrates the outer wall of the oil storage bottle 7 and extends longitudinally away from the oil storage bottle 7, and the third oil-conducting cotton 8 is accommodated in the capillary conduit 4 , one end of the third oil-guiding cotton 8 is in contact with the e-liquid in the oil storage bottle 7, and an oil injection hole 10 is provided on the side wall of the oil storage bottle 7;

[0027] The end of the capillary conduit 4 away from the oil storage bottle 7 is provided with an oil guide tube 5, and a spiral heating wire 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com