Dust removal equipment with high efficiency and strong purification effect

A dust removal equipment and high-efficiency technology, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve problems such as inability to classify, uneven particle size distribution of solid particles, increased operational difficulty and procedures, etc., to achieve Improve high temperature corrosion resistance and thermal shock resistance, improve impact resistance and mechanical quality, improve temperature resistance and mechanical quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

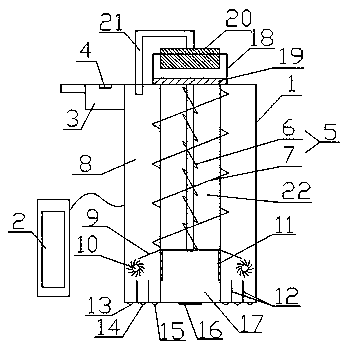

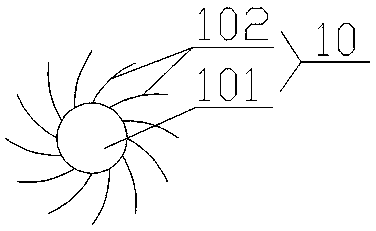

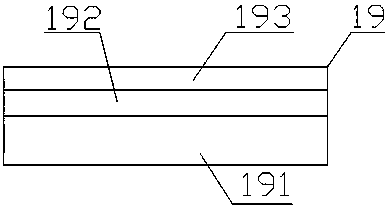

[0038] A dust removal device with high efficiency and strong purification effect, including a housing 1, a control device 2 and a gas collection chamber 3, the housing 1 is provided with a rotating mechanism 5, and the rotating mechanism 5 is composed of an inner rotating mechanism 6 It is composed of an external rotating mechanism 7, an external air chamber 8 is formed between the external rotating mechanism 7 and the housing 1, an internal air chamber 22 is formed between the external rotating mechanism 7 and the internal rotating mechanism 6, and the described The bottom of the external air chamber 8 is provided with an air-introducing plate 9, a runner 10 and an isolation plate 12, and the bottom partition wall between the external air chamber 8 and the internal air chamber 22 is provided with a first filter mechanism 11, so The top of the housing 1 is also provided with a second filter mechanism 18 .

[0039] Further, the gas collection chamber 3 is located on the top of ...

Embodiment 2

[0064] A dust removal device with high efficiency and strong purification effect, including a housing 1, a control device 2 and a gas collection chamber 3, the housing 1 is provided with a rotating mechanism 5, and the rotating mechanism 5 is composed of an inner rotating mechanism 6 It is composed of an external rotating mechanism 7, an external air chamber 8 is formed between the external rotating mechanism 7 and the housing 1, an internal air chamber 22 is formed between the external rotating mechanism 7 and the internal rotating mechanism 6, and the described The bottom of the external air chamber 8 is provided with an air-introducing plate 9, a runner 10 and an isolation plate 12, and the bottom partition wall between the external air chamber 8 and the internal air chamber 22 is provided with a first filter mechanism 11, so The top of the housing 1 is also provided with a second filter mechanism 18 .

[0065] Further, the gas collection chamber 3 is located on the top of ...

Embodiment 3

[0090] A dust removal device with high efficiency and strong purification effect, including a housing 1, a control device 2 and a gas collection chamber 3, the housing 1 is provided with a rotating mechanism 5, and the rotating mechanism 5 is composed of an inner rotating mechanism 6 It is composed of an external rotating mechanism 7, an external air chamber 8 is formed between the external rotating mechanism 7 and the housing 1, an internal air chamber 22 is formed between the external rotating mechanism 7 and the internal rotating mechanism 6, and the described The bottom of the external air chamber 8 is provided with an air-introducing plate 9, a runner 10 and an isolation plate 12, and the bottom partition wall between the external air chamber 8 and the internal air chamber 22 is provided with a first filter mechanism 11, so The top of the housing 1 is also provided with a second filter mechanism 18 .

[0091] Further, the gas collection chamber 3 is located on the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com