Patents

Literature

30results about How to "Facilitate subsequent recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

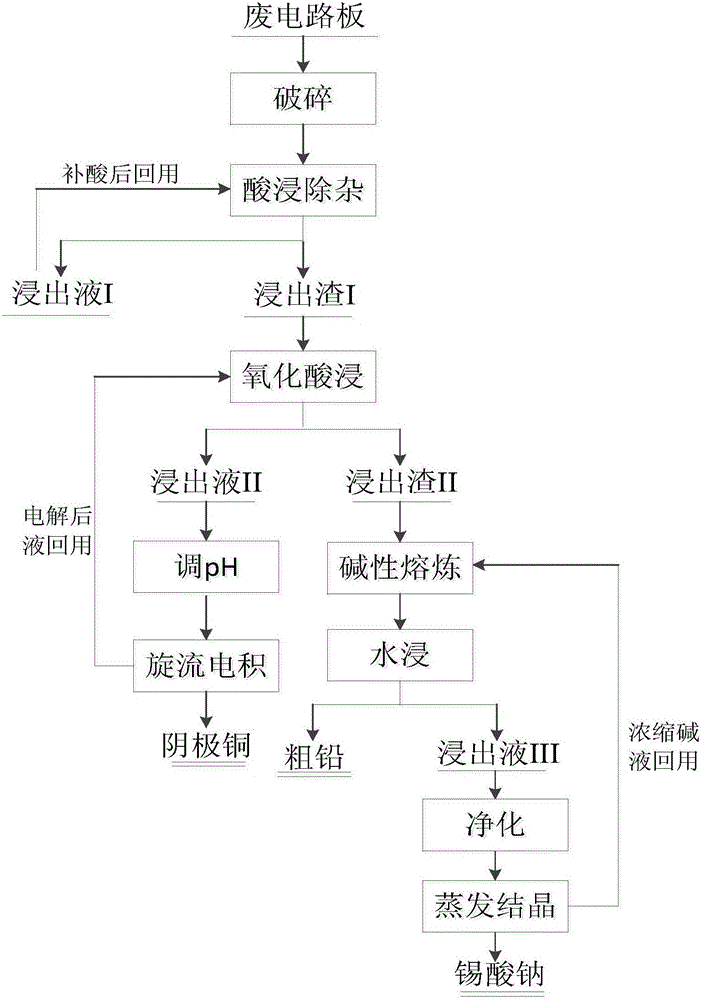

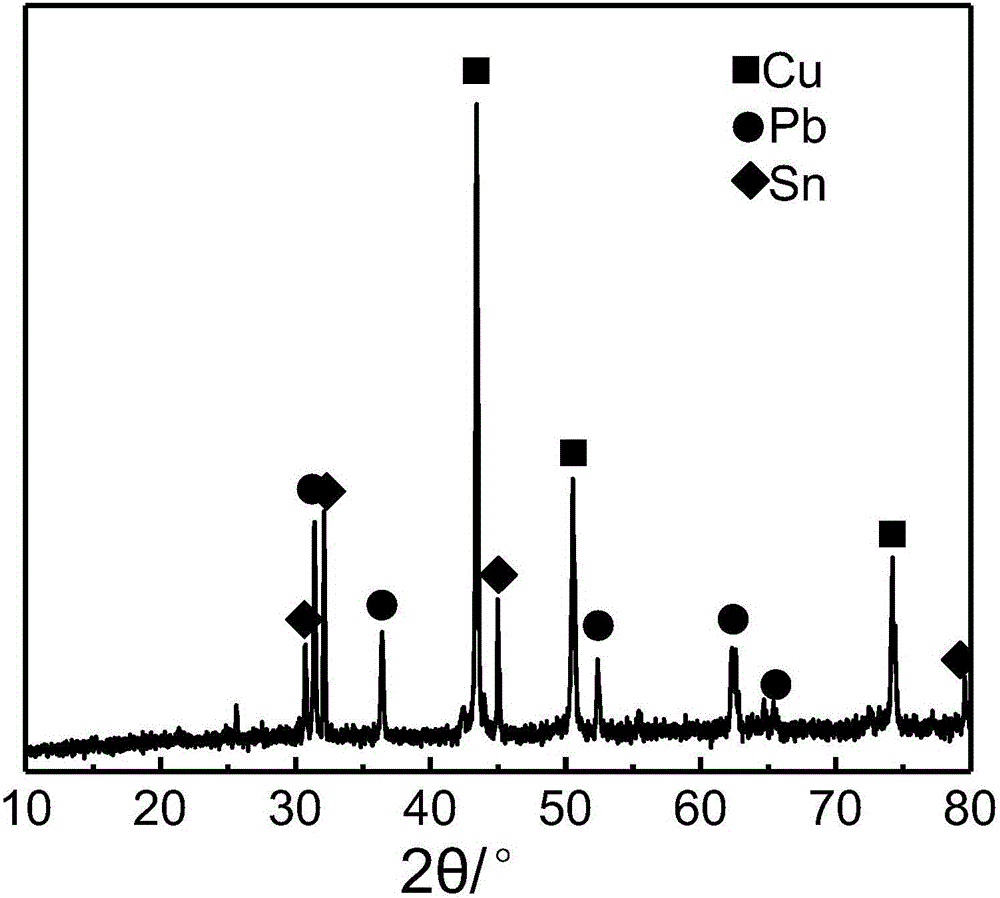

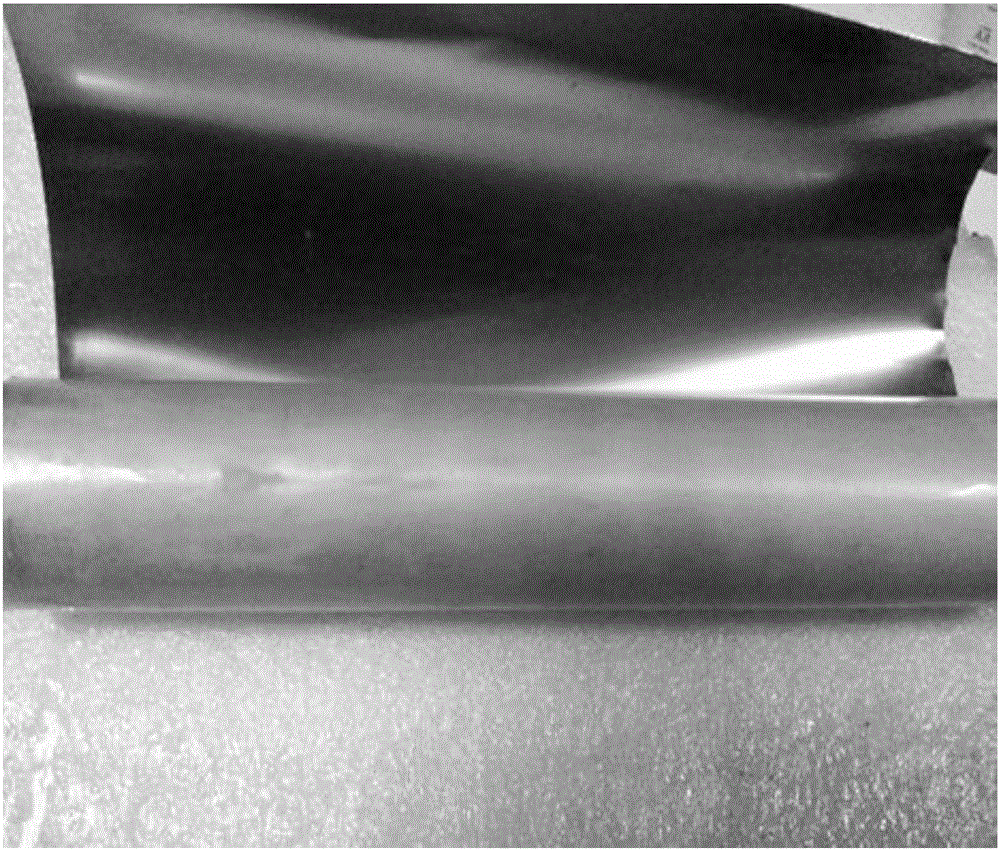

Method for recycling valuable metal in waste circuit board

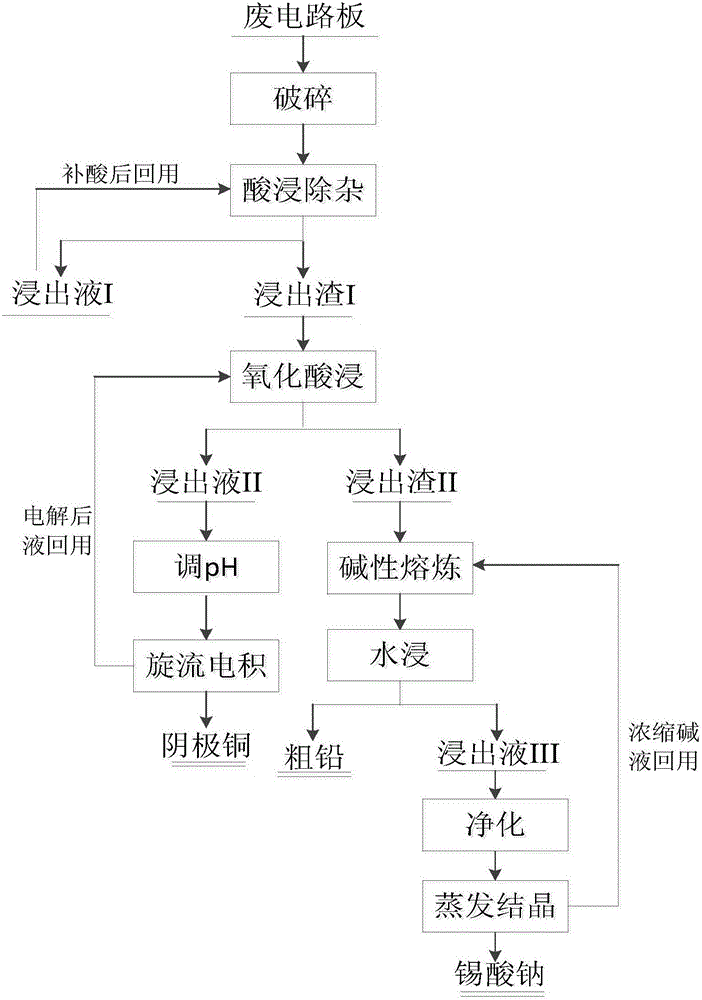

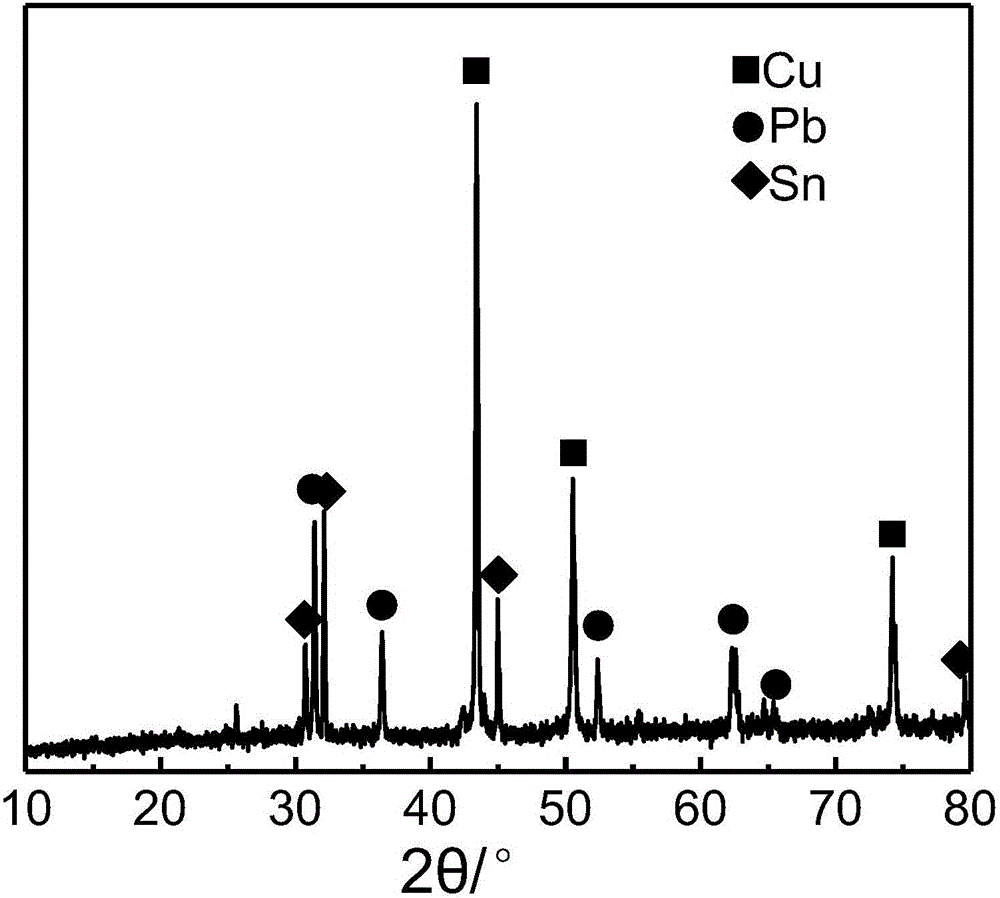

The invention discloses a method for recycling valuable metal in a waste circuit board. The method includes the following steps that the waste circuit board is subject to smashing and reselection to prepare multi-metal powder; a dilute acid solution is added into the multi-metal powder, agitation leaching is carried out, filtering is carried out, and leaching slag I and leaching liquid I are obtained; an acid solution is added into the leaching slag I according to the liquid-solid mass ratio of the acid solution to the leaching slag I being 10-40:1, then an oxidizing agent is added, agitation leaching is carried out, filtering is carried out after leaching is finished, and leaching slag II and leaching liquid II are obtained; the leaching liquid II is subject to cyclone electrodeposition to obtain cathode copper and an after-electrolysis solution; alkali and a reducing agent are added into the leaching slag II, smelting is carried out under the condition that the temperature ranges from 400 DEG C to 600 DEG C, water leaching is carried out, filtering is carried out, and lead bullion containing precious metal and leaching liquid III are obtained; and the leaching liquid III is purified and is subject to evaporation and concentration to obtain a concentrated alkali solution and sodium stannate crystals. According to the method for recycling the valuable metal in the waste circuit board, the procedure is short, the efficiency is high, the cost is low, cleanness is achieved, and pollution is avoided.

Owner:广西自贸区西江资源循环科技产业股份有限公司

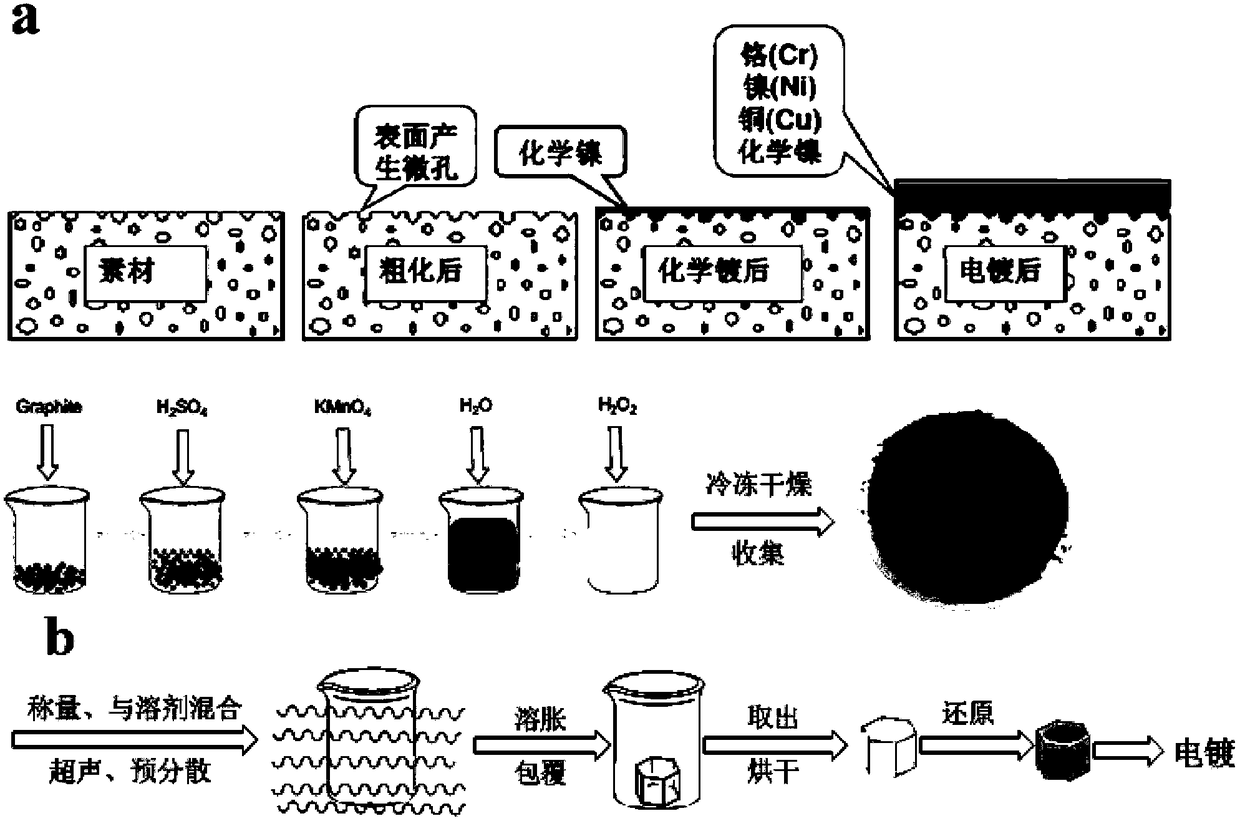

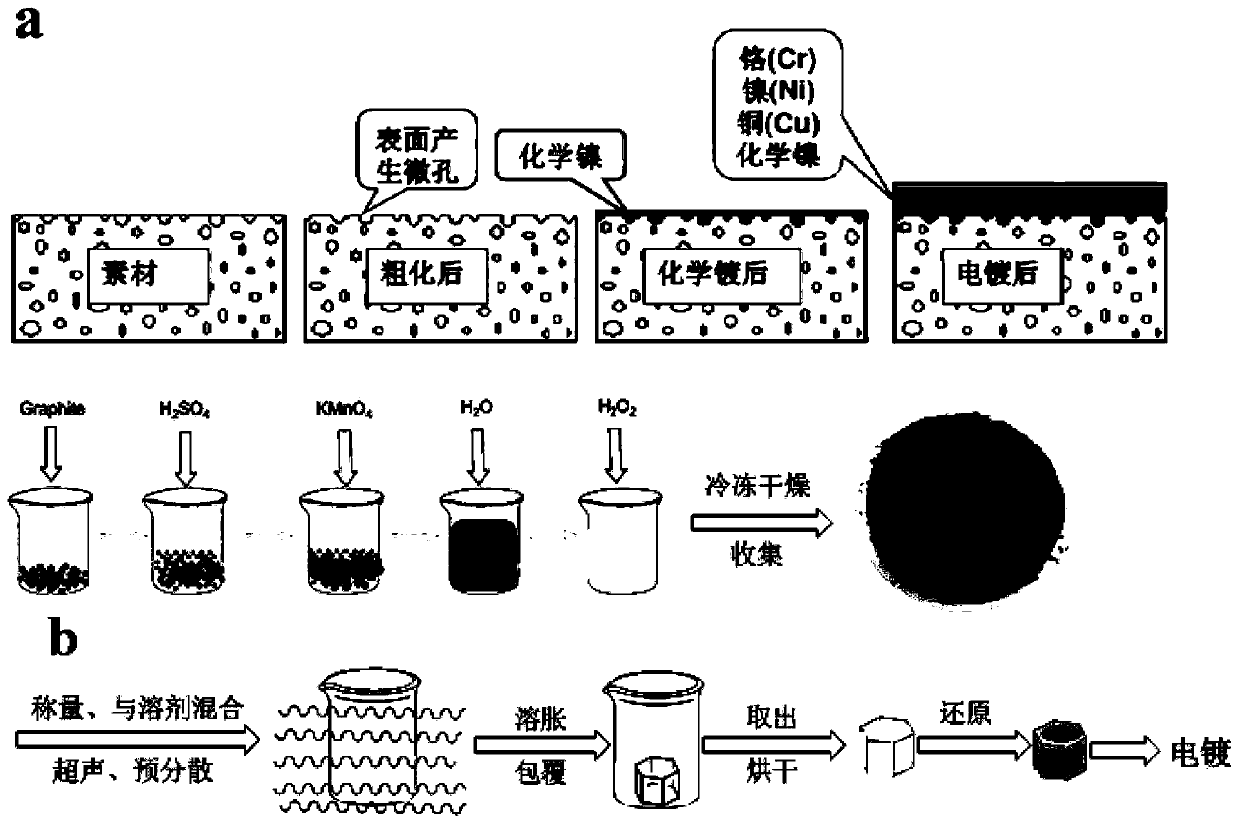

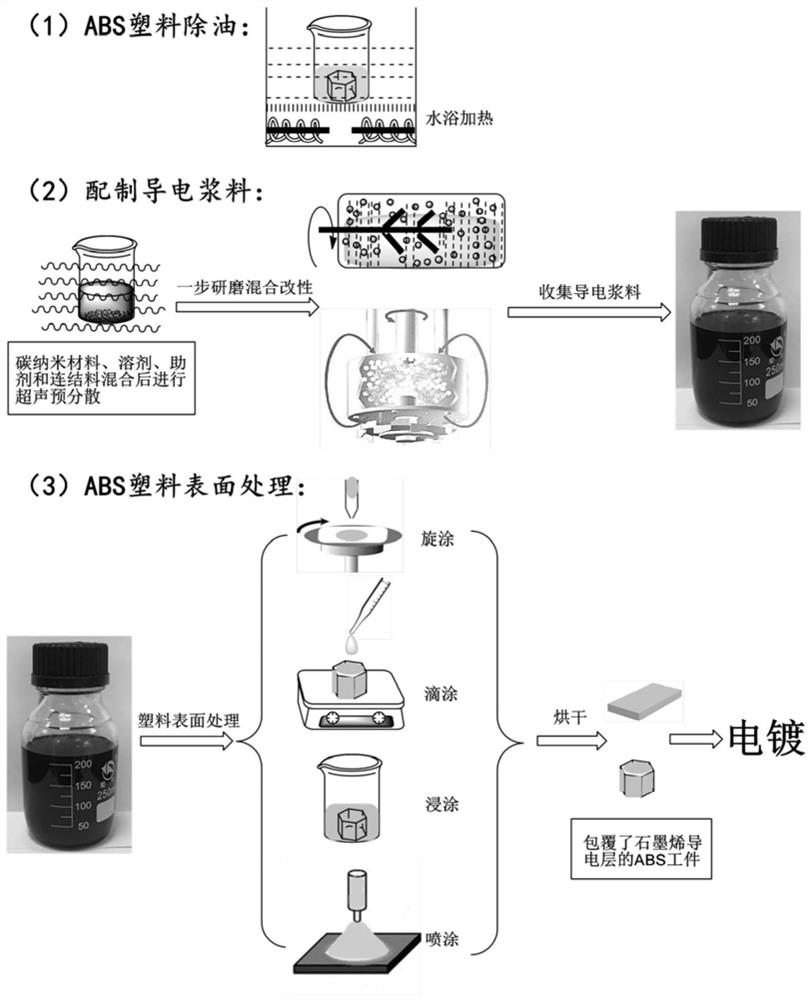

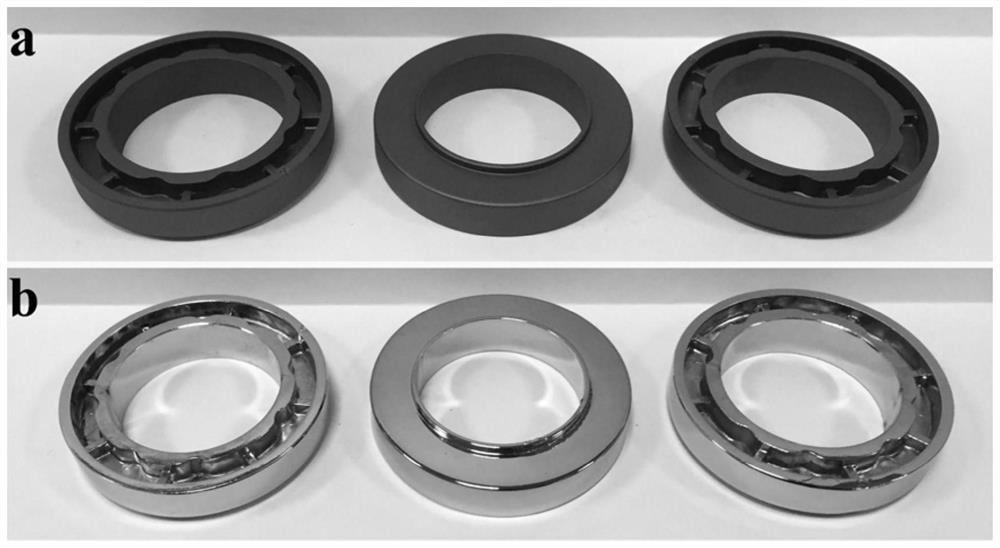

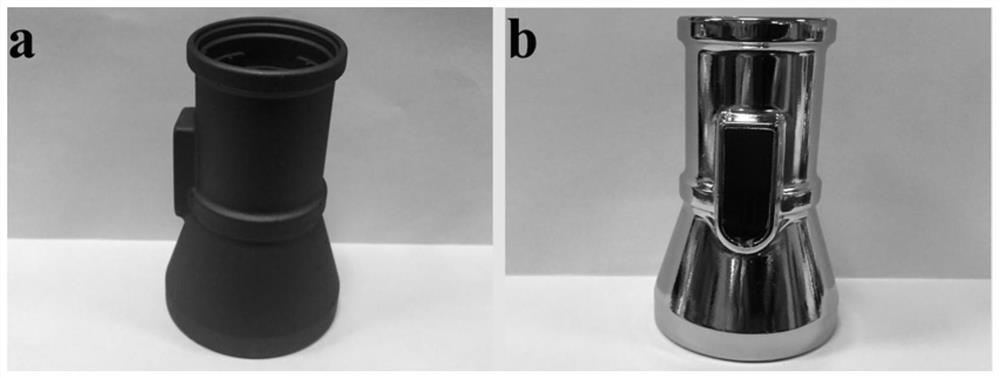

Surface treatment method for ABS plastic electroplating

The invention discloses a surface treatment method for ABS plastic electroplating. A one-step swelling-coating graphene oxide secondary-reduction process is adopted; a uniform and continuous conductive layer is directly formed on the surface of an ABS product; the using of heavy metal salts and precious metals is avoided, the technical process and cost are largely reduced; the surface treatment method is simple and efficient and is easy to perform; the operability is high, the cost is low, and the surface treatment method is suitable for industrial large-scale production and application and has an important application value.

Owner:HUAQIAO UNIVERSITY +1

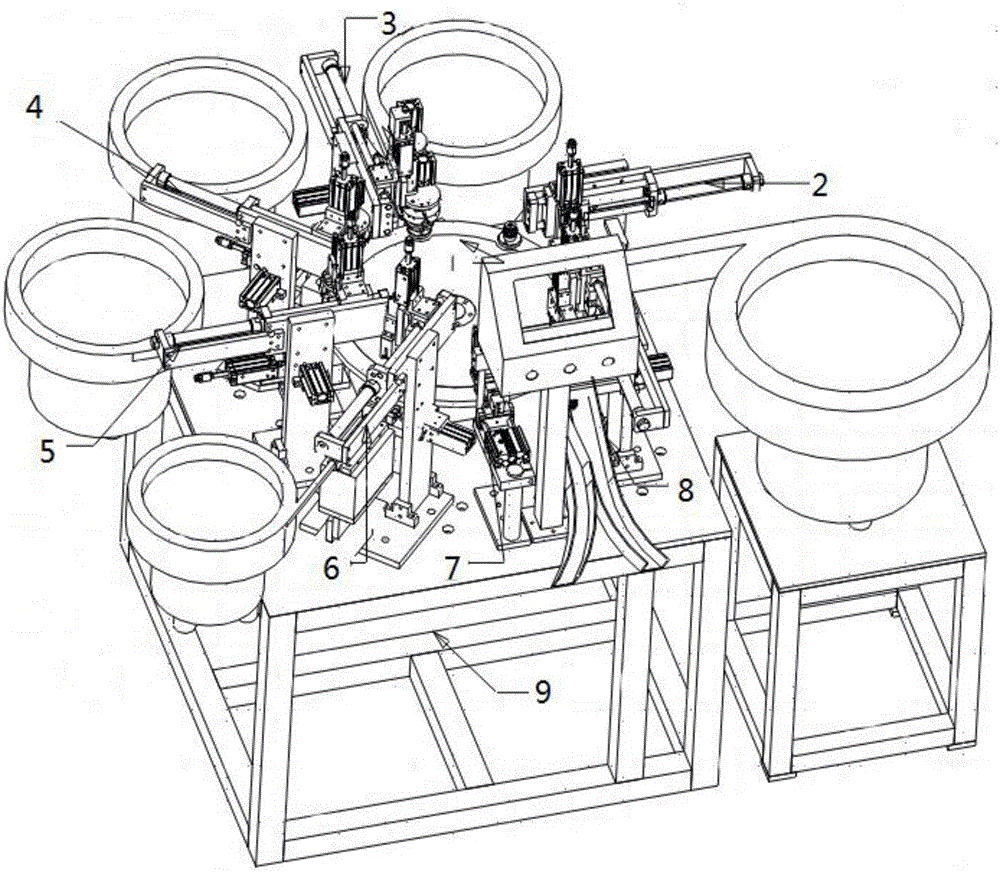

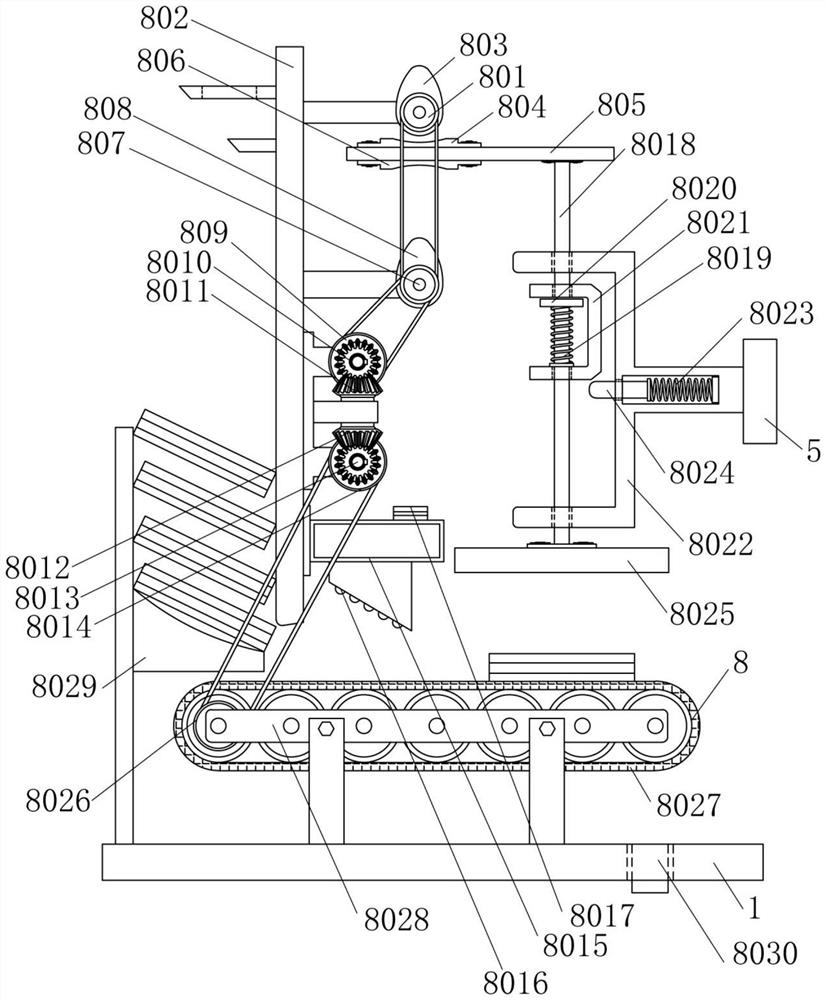

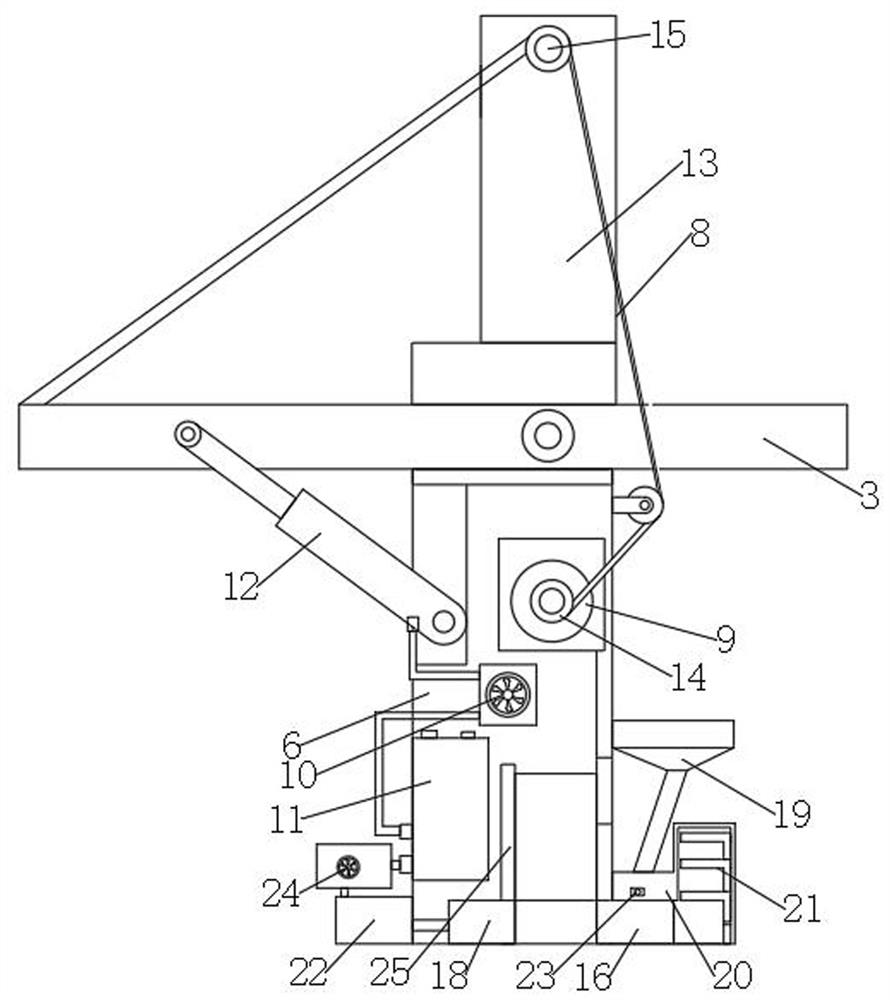

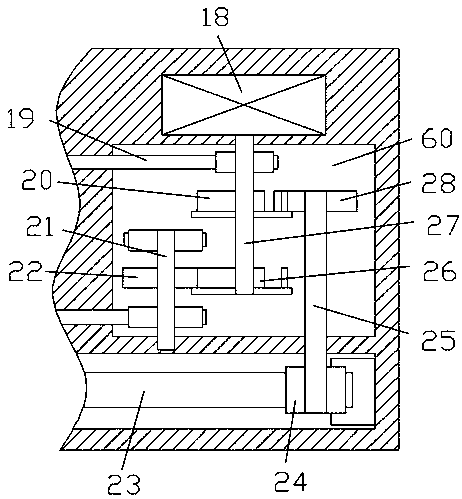

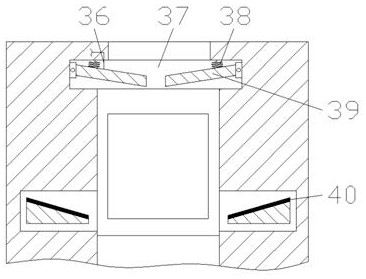

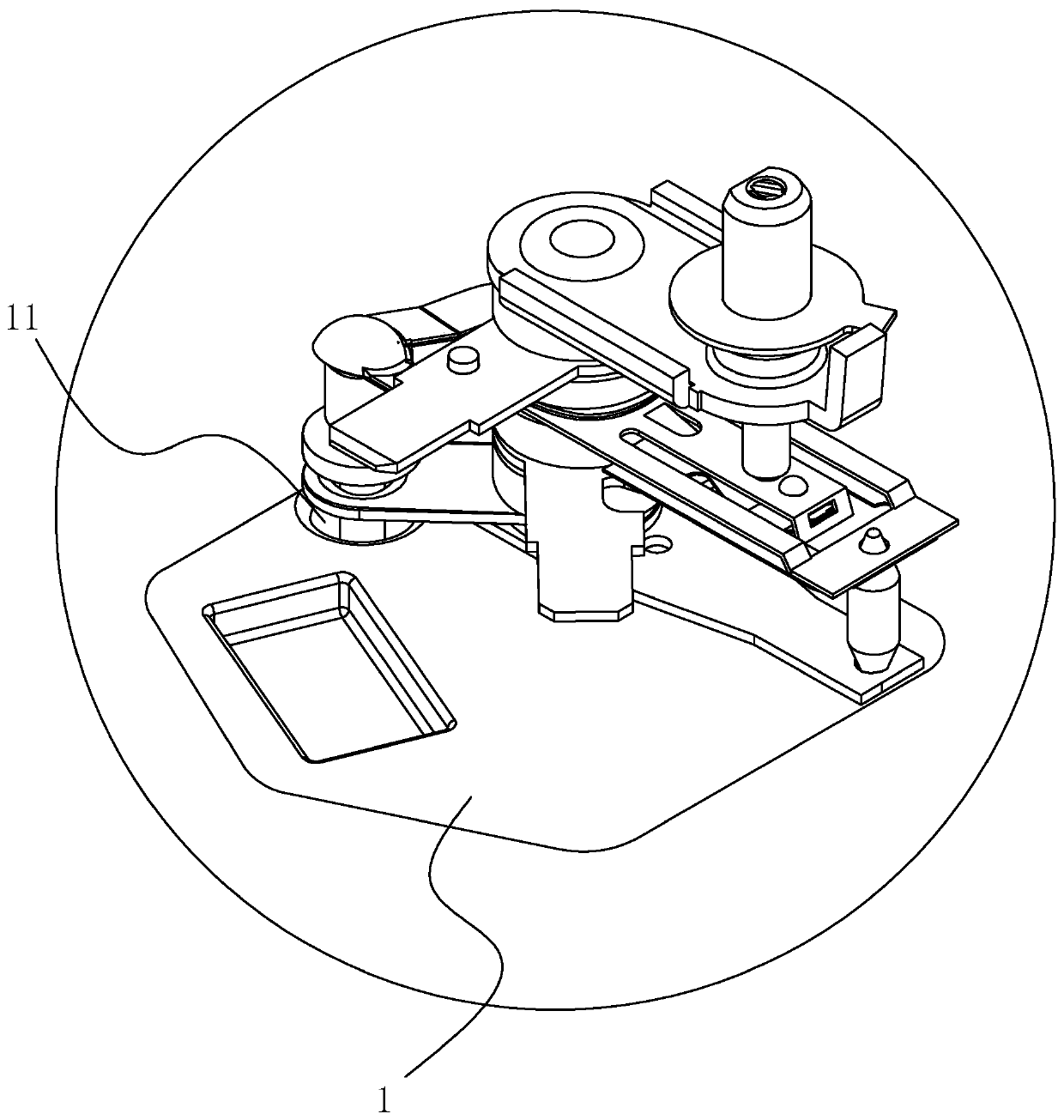

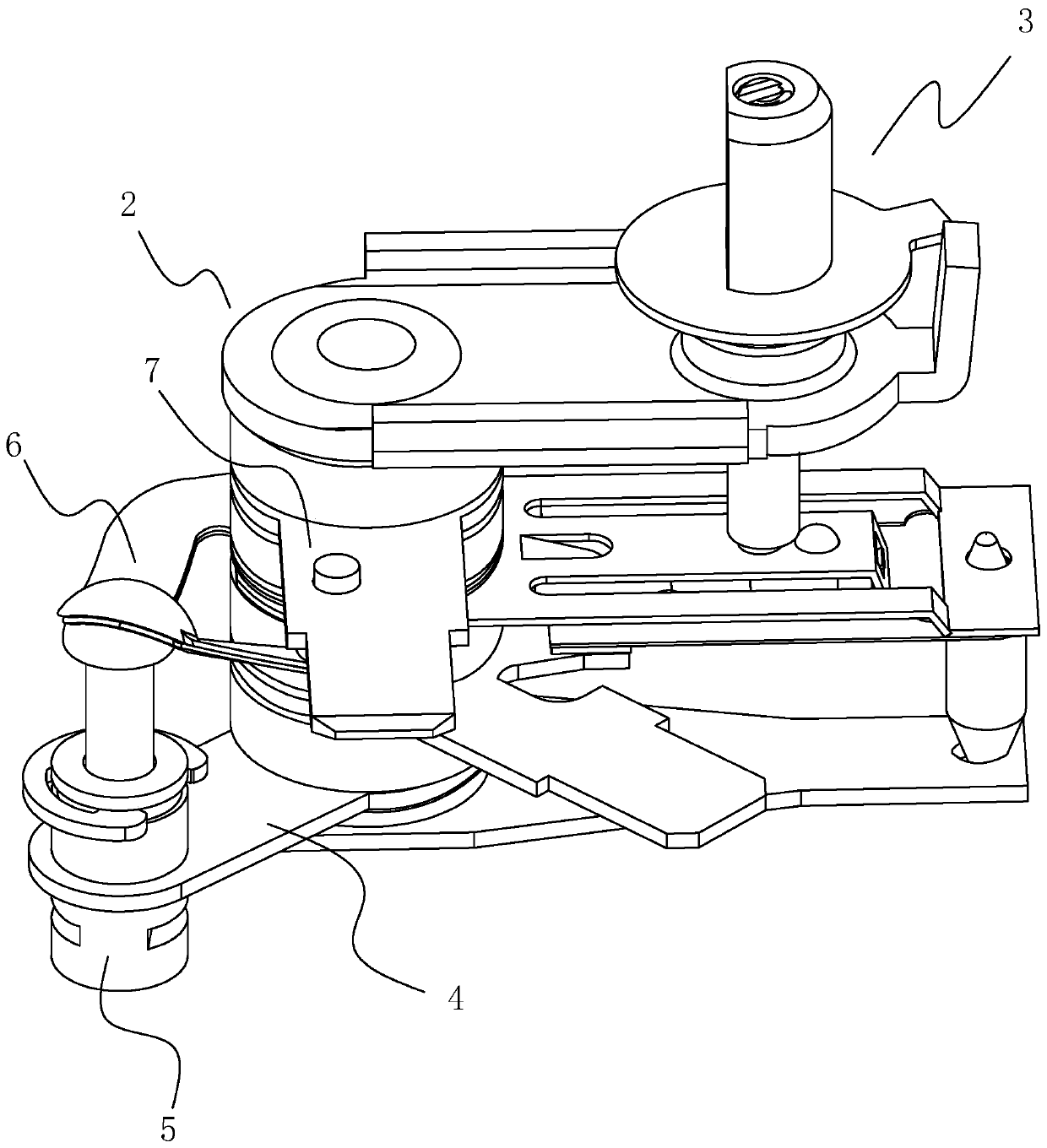

Control valve superior and inferior product checking and sorting mechanism, control valve machining equipment and machining and control method

InactiveCN105881020AIncrease productivityImprove product qualityAssembly machinesGeological measurementsMachine controlEngineering

The invention discloses a quality control valve inspection and classification mechanism, control valve processing equipment and a processing and control method, and belongs to the technical field of control valve assembly equipment. It includes a turntable dividing mechanism and an electric control system, as well as an automatic feeding and installation mechanism and a valve control outlet mechanism. The automatic feeding equipment of the mechanism receives the control valve to be processed, and the installation equipment of the automatic feeding and installation mechanism installs and processes the components on the control valve. The control valve is discharged, and the turntable dividing mechanism is evenly equipped with control valve fixtures, and the automatic feeding equipment of the automatic feeding and installation mechanism places the control valves on the control valve fixtures. It uses a manipulator to place it precisely, saves labor, realizes automation, and improves production efficiency and quality.

Owner:ANHUI LAITE GAS SPRING CO LTD

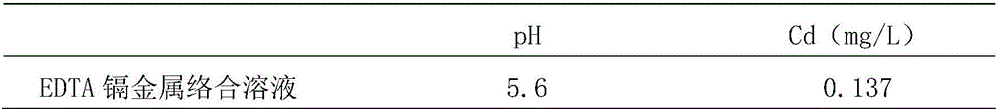

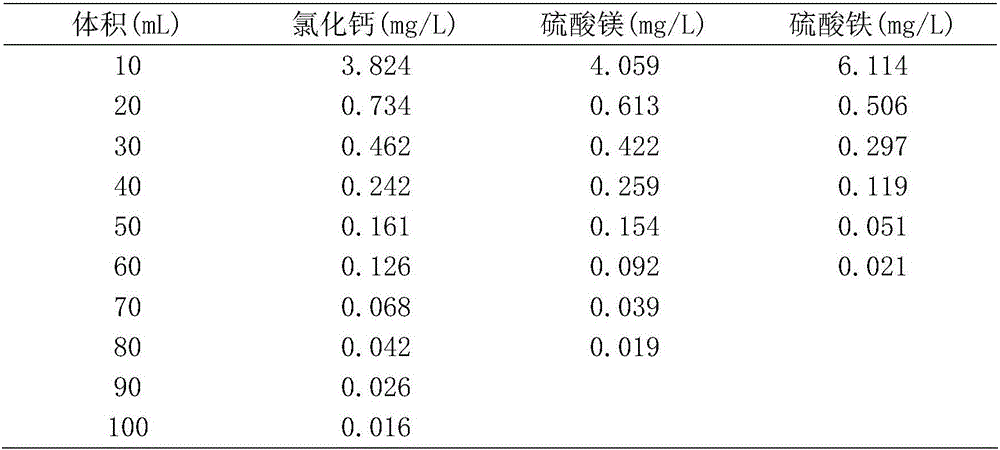

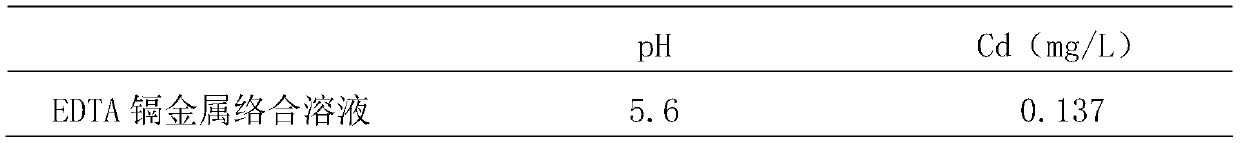

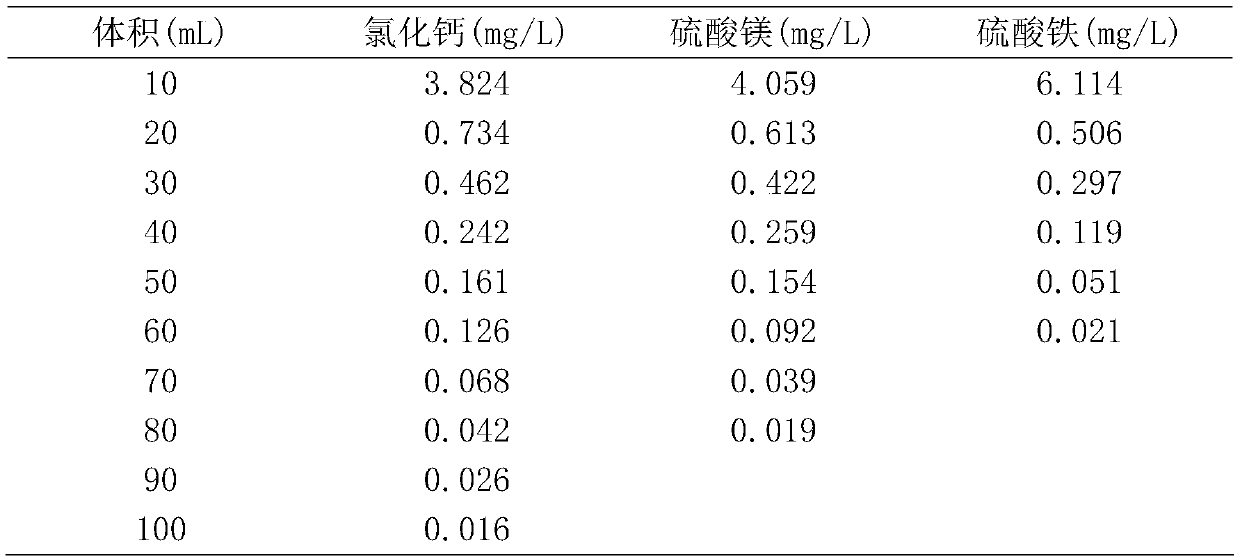

Method for recycling EDTA metal complex and regenerating chlorine type anion exchange resin by utilizing metallic salt solution

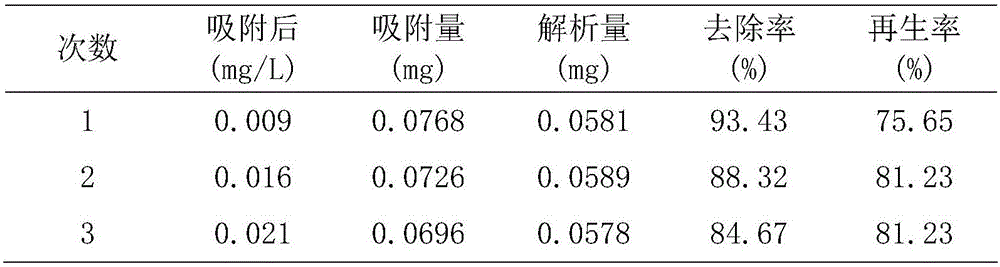

ActiveCN106732832AGood regeneration performanceHigh recovery rateOrganic compound preparationIon-exchanger regenerationChemistryAbsorption effect

The invention relates to a method for recycling an EDTA metal complex and regenerating chlorine type anion exchange resin by utilizing a metallic salt solution. The method comprises the following steps: utilizing the chlorine type anion exchange resin to absorb an EDTA cadmium metal complex; taking the chlorine type anion exchange resin loaded with the EDTA cadmium metal complex as a treating object; selecting the metallic salt solution as a regenerating agent; dynamically regenerating the absorbed chlorine type anion exchange resin; treating the regenerated solution; and recycling EDTA and metal cadmium. After the treatment according to the method, the EDTA cadmium metal complex in a complex solution can be effectively recycled, and after the resin is reused for several times, the resin still has a better absorption effect, so that convenience is brought to the future large-scale test, a certain treatment time and cost are reduced, and the secondary pollution to the environment caused by the EDTA metal complex solution can be reduced.

Owner:HUNAN AGRICULTURAL UNIV

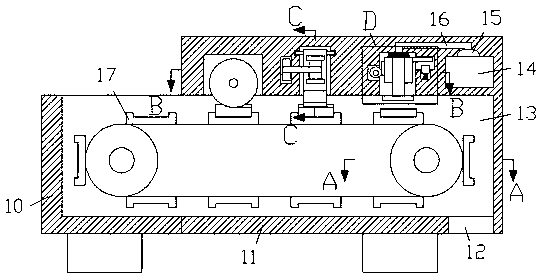

Self-cleaning numerical control machine tool

InactiveCN108994659AEasy to cleanEasy to operateMaintainance and safety accessoriesPressesElectric machineryEngineering

The invention discloses a self-cleaning numerical control machine tool. The self-cleaning numerical control machine tool comprises a machine tool shell, wherein a first shell is fixed to the outer wall of one side of the machine tool shell by virtue of a bolt, a motor is fixed to the side wall of the first shell by virtue of a bolt, a square hole is formed in a position, which is close to the first shell, of the side wall of the machine tool shell, a rubber roller is movably connected to the inner wall of the first shell by virtue of a bearing, nylon bristles which are distributed at equal intervals are clamped on the side wall of the rubber roller, a slope board is fixed to the outer wall of one side, which is far from the first shell, of the machine tool shell by virtue of a bolt, baffles are respectively fixed to both sides of the slope board by virtue of bolts, and two telescopic flat rods are fixed to a position, which is close to the top end of the rubber roller, of the outer wall of one side of the machine tool shell. According to the self-cleaning numerical control machine tool, processing scraps of the machine tool can be blown to move to one side, so that the scraps are conveniently cleaned and collected, and the self-cleaning numerical control machine tool has the advantages of simplicity in operation, high degree of automation and cleanliness and is favorable for improving the working efficiency and improving the environment of a machine tool processing station.

Owner:滁州立特机械加工有限公司

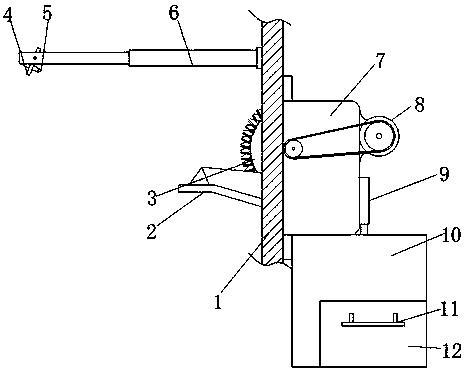

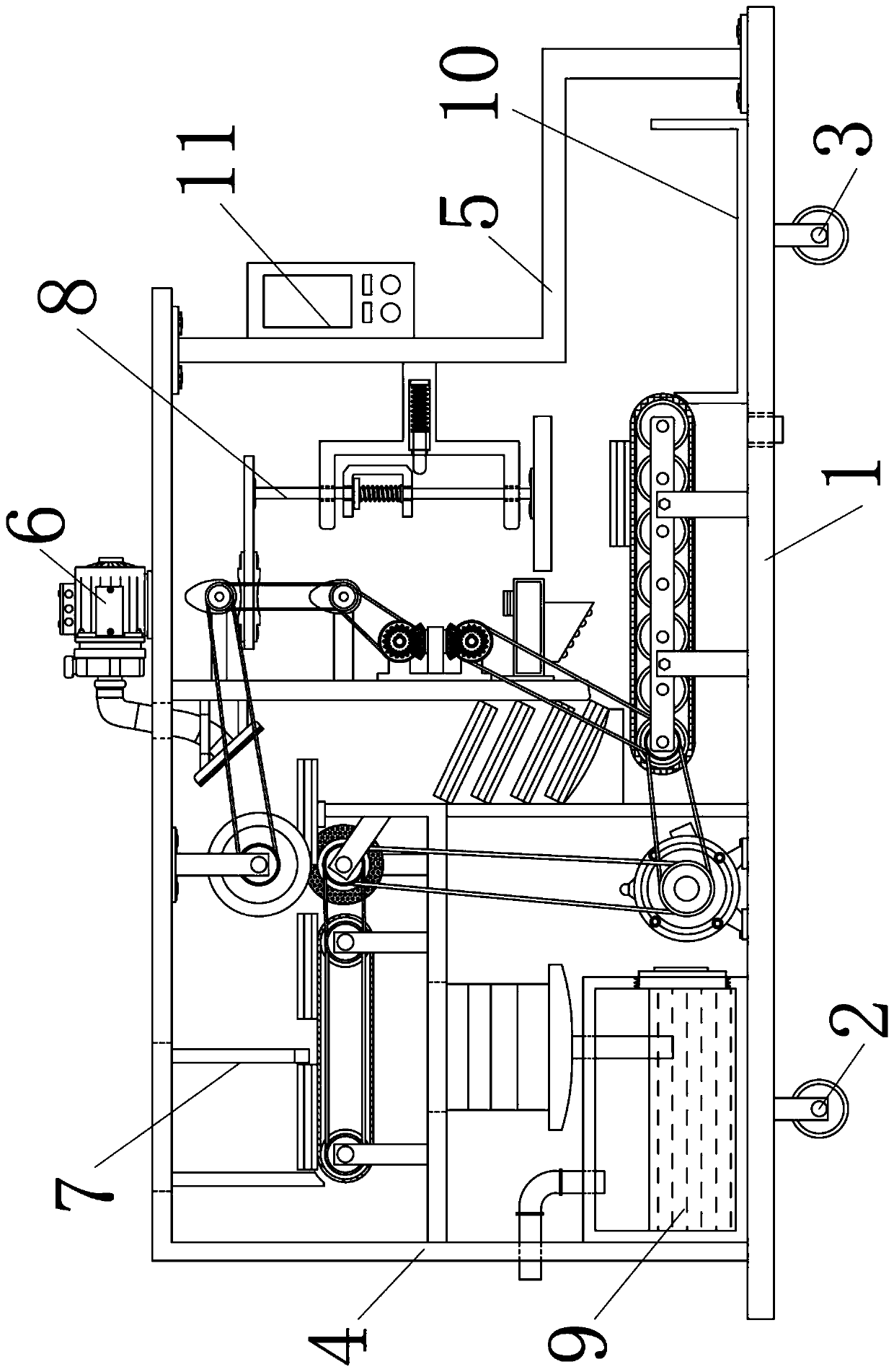

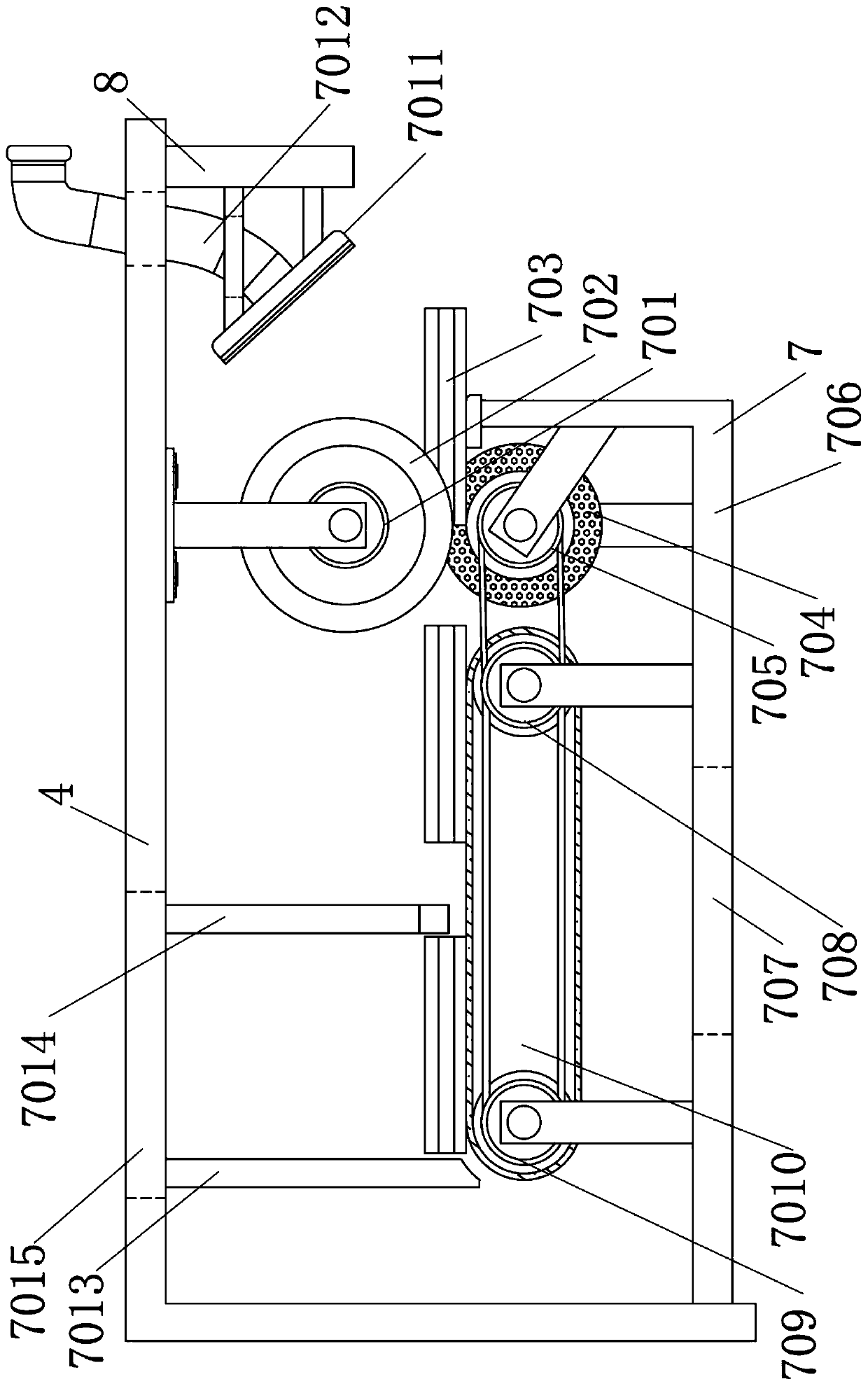

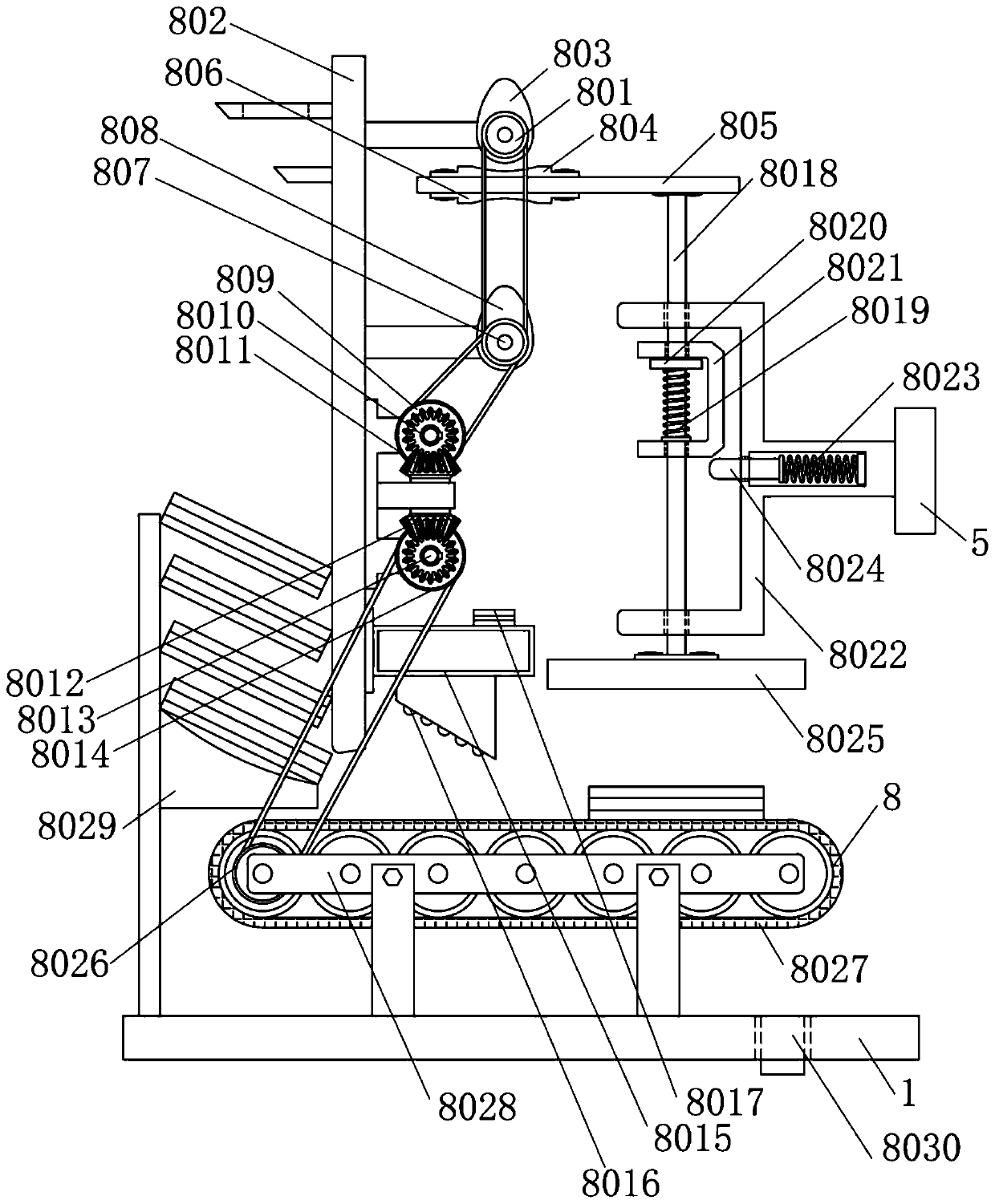

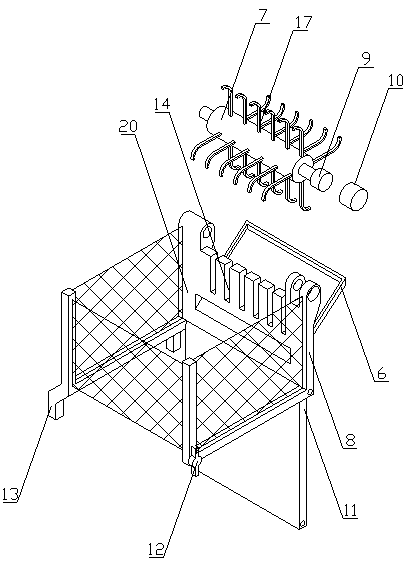

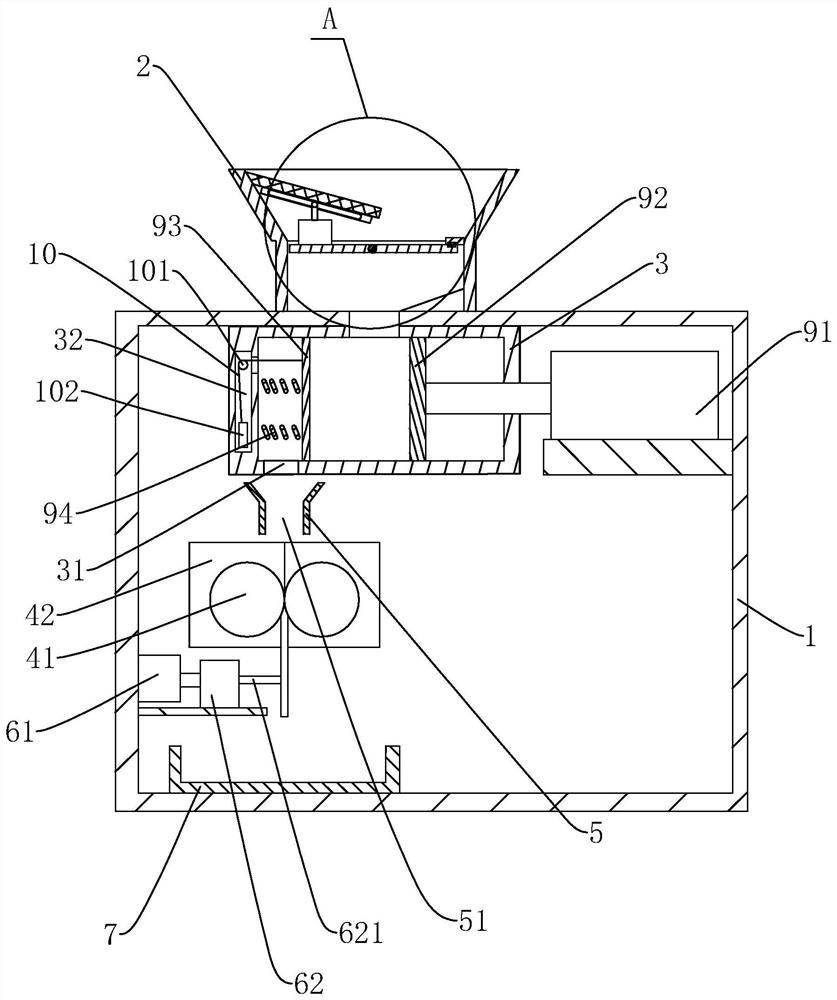

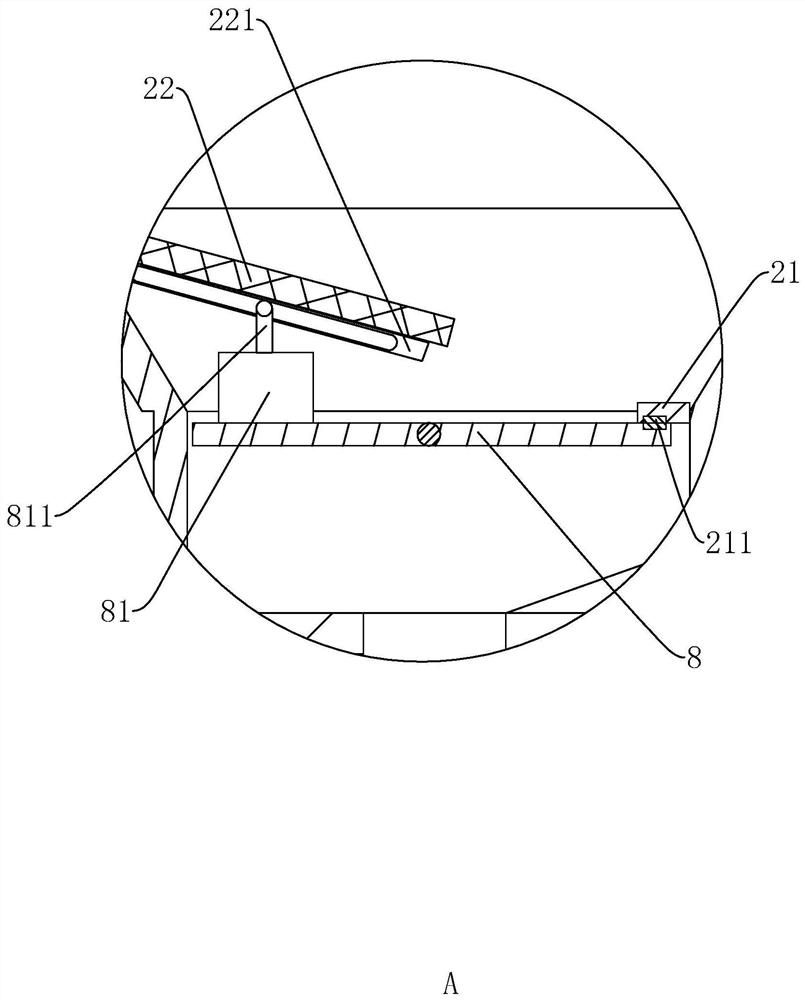

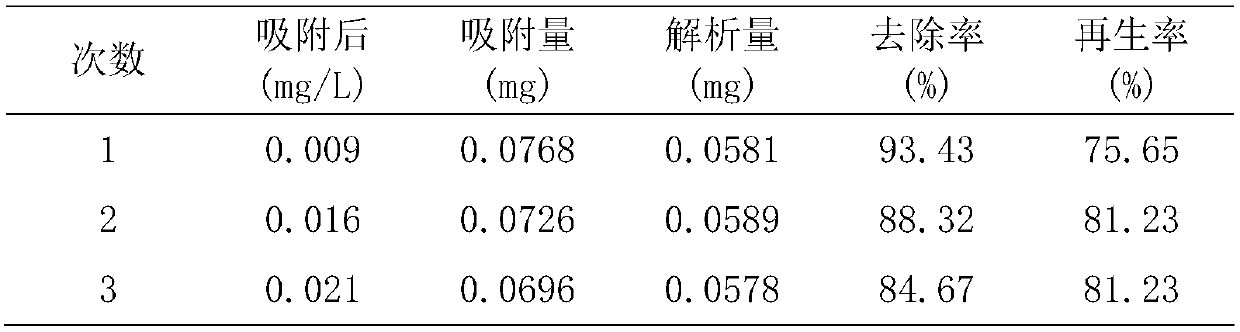

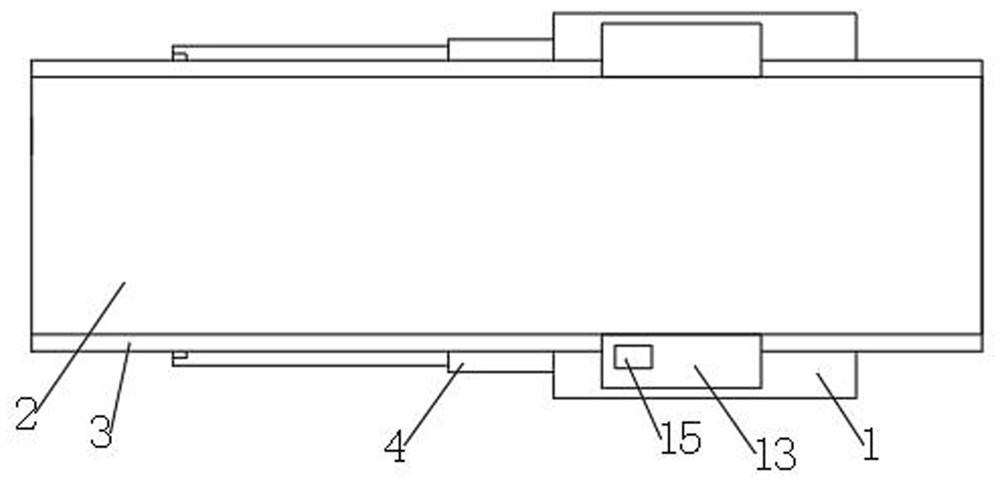

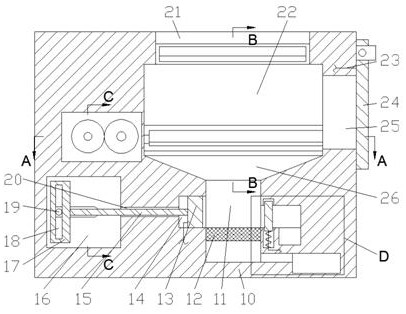

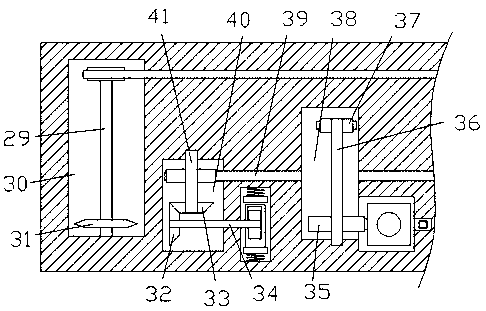

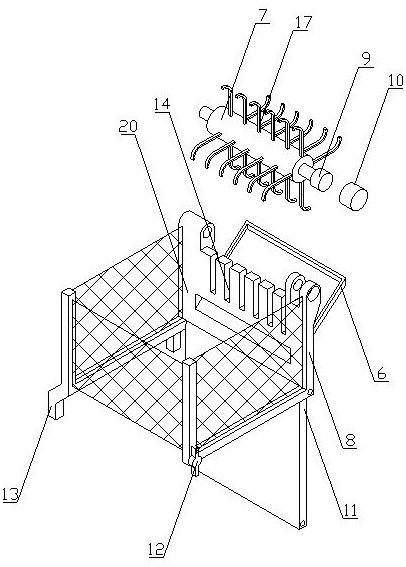

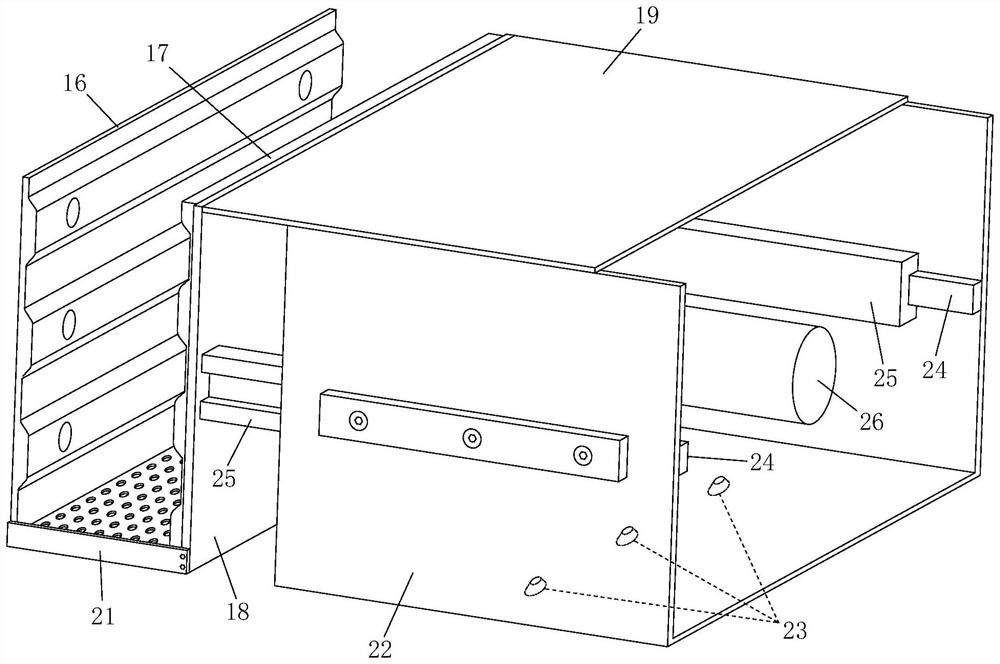

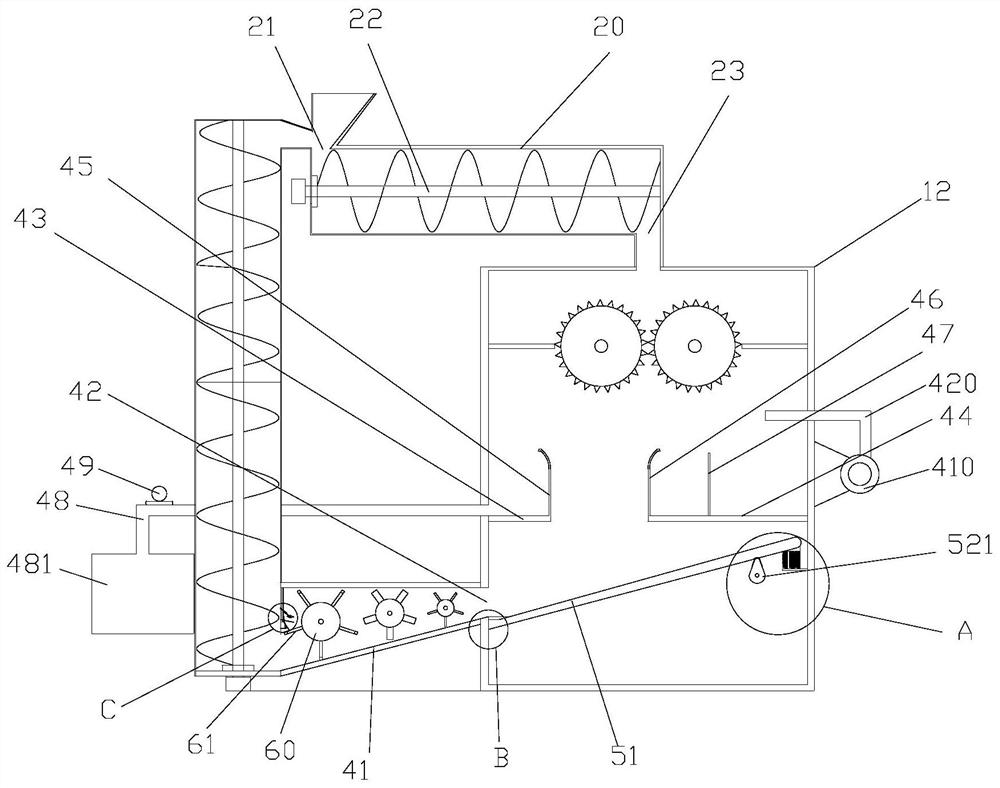

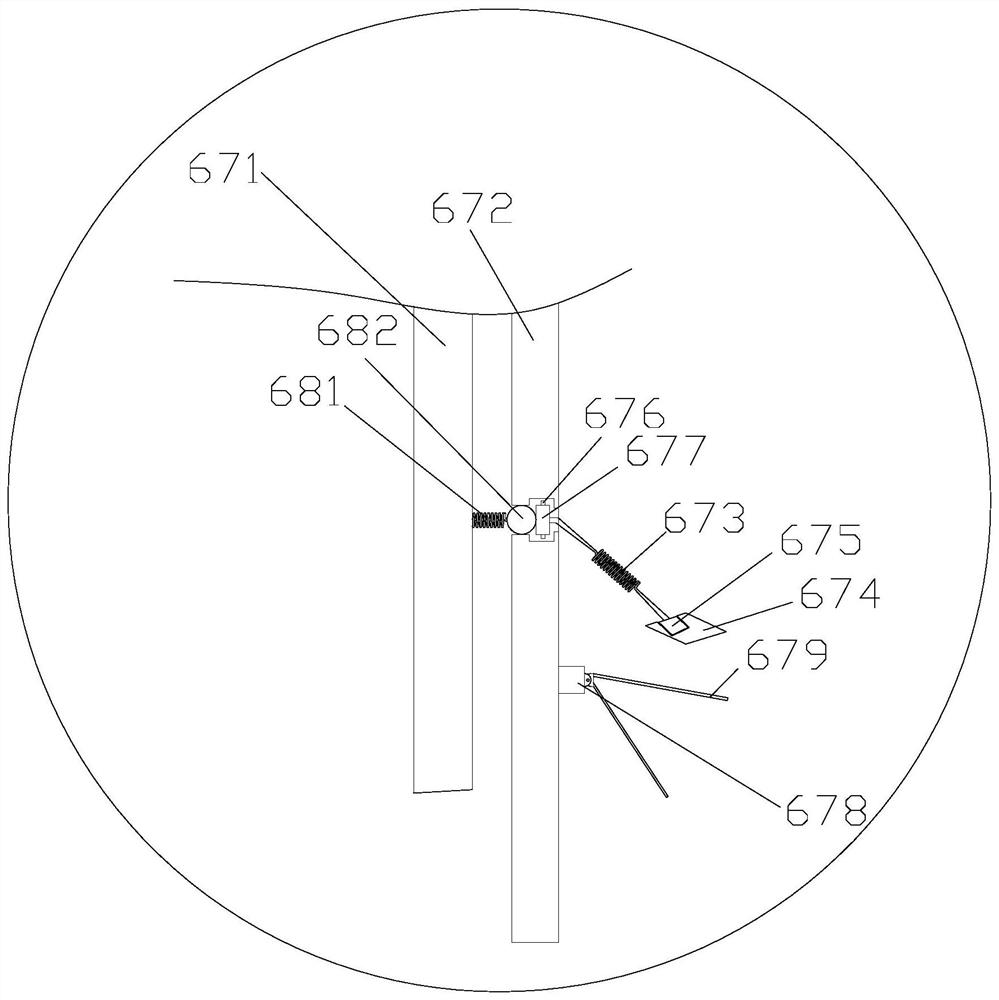

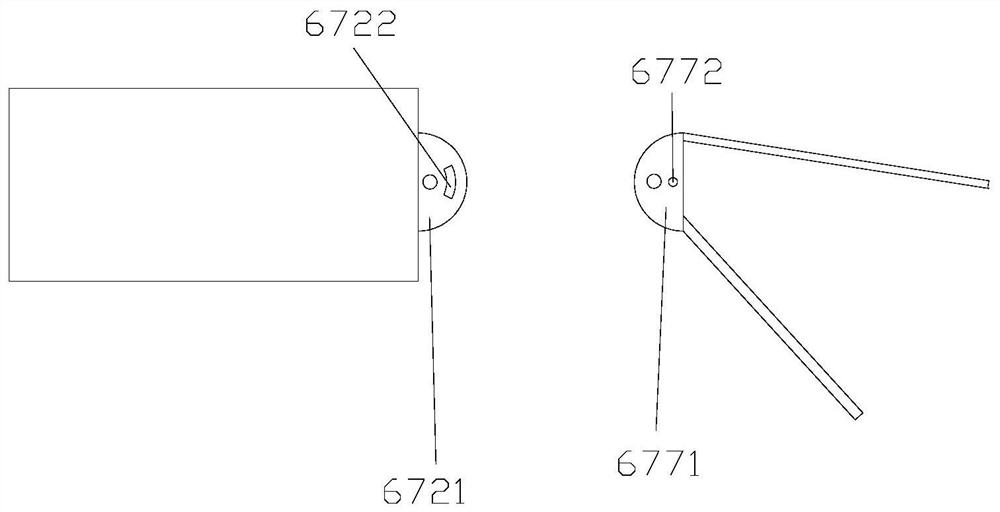

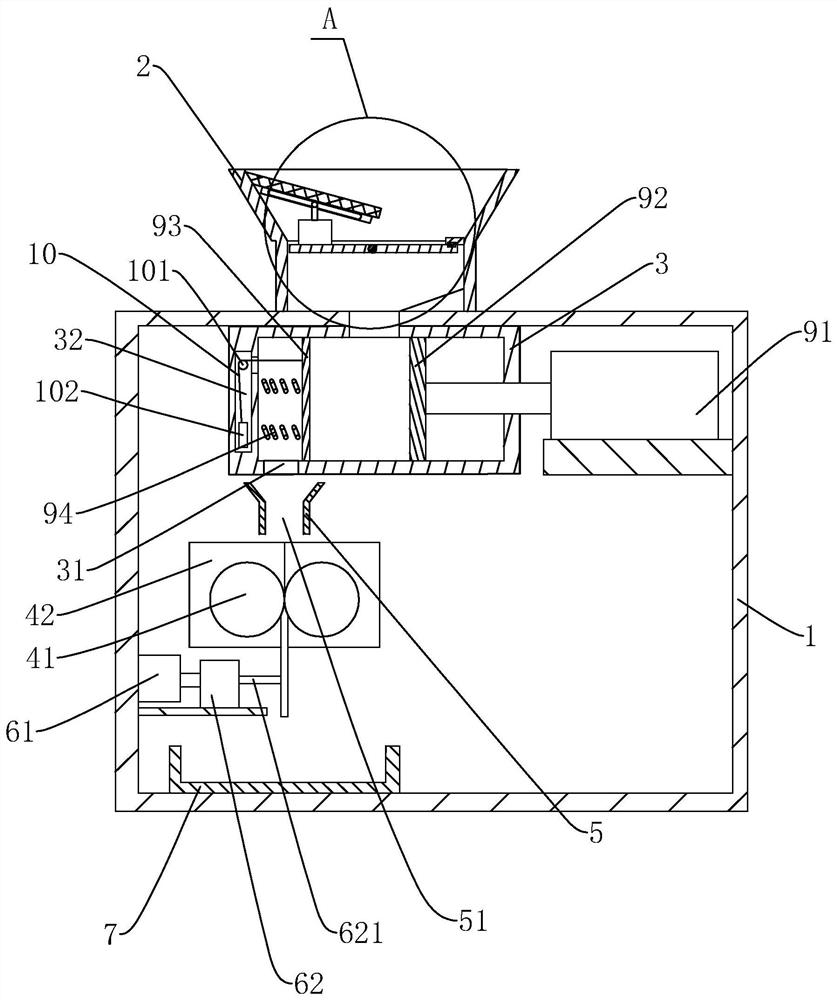

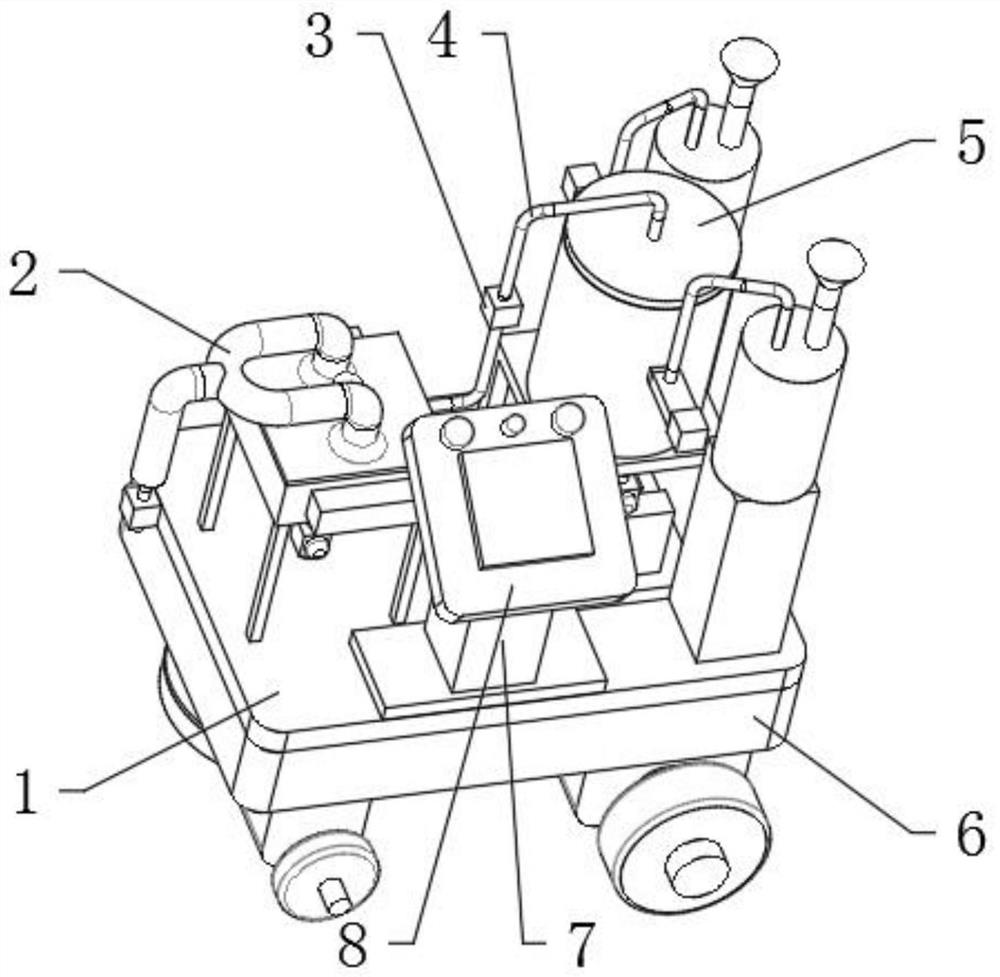

Dust-free recycling pretreatment device for tiles

ActiveCN111530533AGood for healthFacilitate subsequent recyclingUsing liquid separation agentGrinding machinesPre treatmentAir pump

The invention relates to a dust-free processing device, in particular to a dust-free recycling pretreatment device for tiles. The technical problem to be solved is to provide the dust-free recycling pretreatment device for the tiles. The dust-free recycling pretreatment device for the tiles comprises a bottom plate, a first wheel, a second wheel, a supporting frame, a first connecting plate, an air pump, an algae removing mechanism, a crushing mechanism, a dust removing mechanism and a collecting basket, wherein the first wheel is arranged at the left portion of the bottom end of the bottom plate, the second wheel is arranged on the right portion of the bottom end of the bottom plate. According to the device, the dust-free tile treatment is achieved, algae on the surface of the tiles are removed, and the tiles are roughly crushed, so that the subsequent tile recycling process is simplified, and obtained raw materials do not contain impurities; and through dust-free treatment, the situation that dust generated during tile treatment leaves the device, so that the environment is damaged, the health of workers and nearby residents is damaged is avoided.

Owner:三明星硕信息科技有限公司

River channel sewage outlet solid waste filtering device

ActiveCN110565770AEasy to cleanAvoid cloggingFatty/oily/floating substances removal devicesSewerage structuresSewageConveyor belt

The invention discloses a river channel sewage outlet solid waste filtering device and discloses a waste filtering device for intercepting solid wastes in sewage and transferring the wastes into a waste storage basket for centralized placement through matching of a conveyor belt and a separating roller. The river channel sewage outlet solid waste filtering device is characterized in that two fixedframes are arranged at the two ends of a connecting seat respectively; two conveying wheels are arranged on the two fixed frames respectively; the two ends of shafts on the conveying wheels are connected with the fixed frames through bearings respectively; the two conveying wheels are connected through the conveyor belt; the middle part of the conveyor belt is a filter screen; the height of the conveyor belt is gradually reduced from one end to the other end; the two sides of the conveyor belt are provided with baffle plates respectively; the two ends of the baffle plates are connected with the two fixed frames respectively; the tops of the baffle plates extend upwards to be higher than the conveyor belt with some distance; a conveyor belt motor is arranged on the connecting seat; a motorshaft on the conveyor belt motor is connected with the shaft on one of the conveying wheels; and the waste storage basket is arranged on one side of the conveyor belt.

Owner:徐州中知知识产权服务有限公司

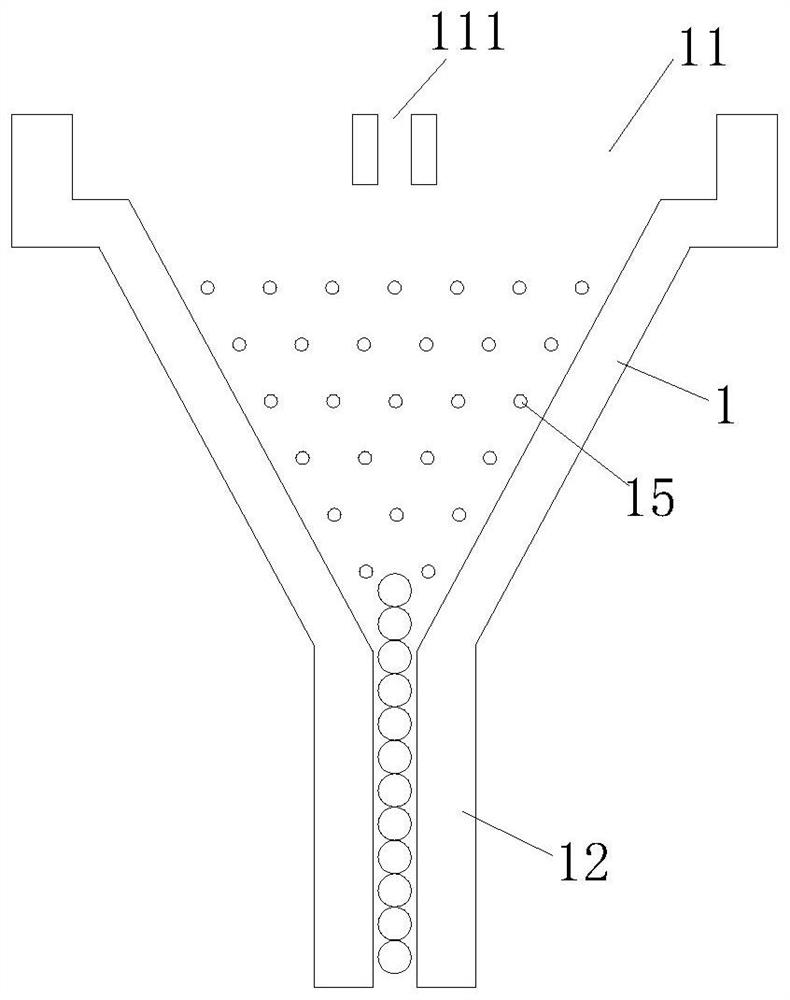

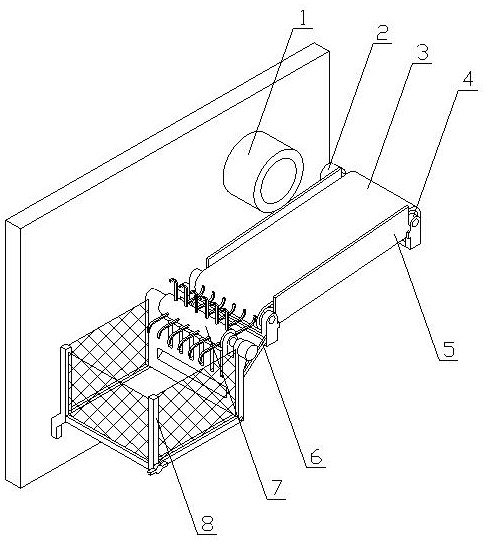

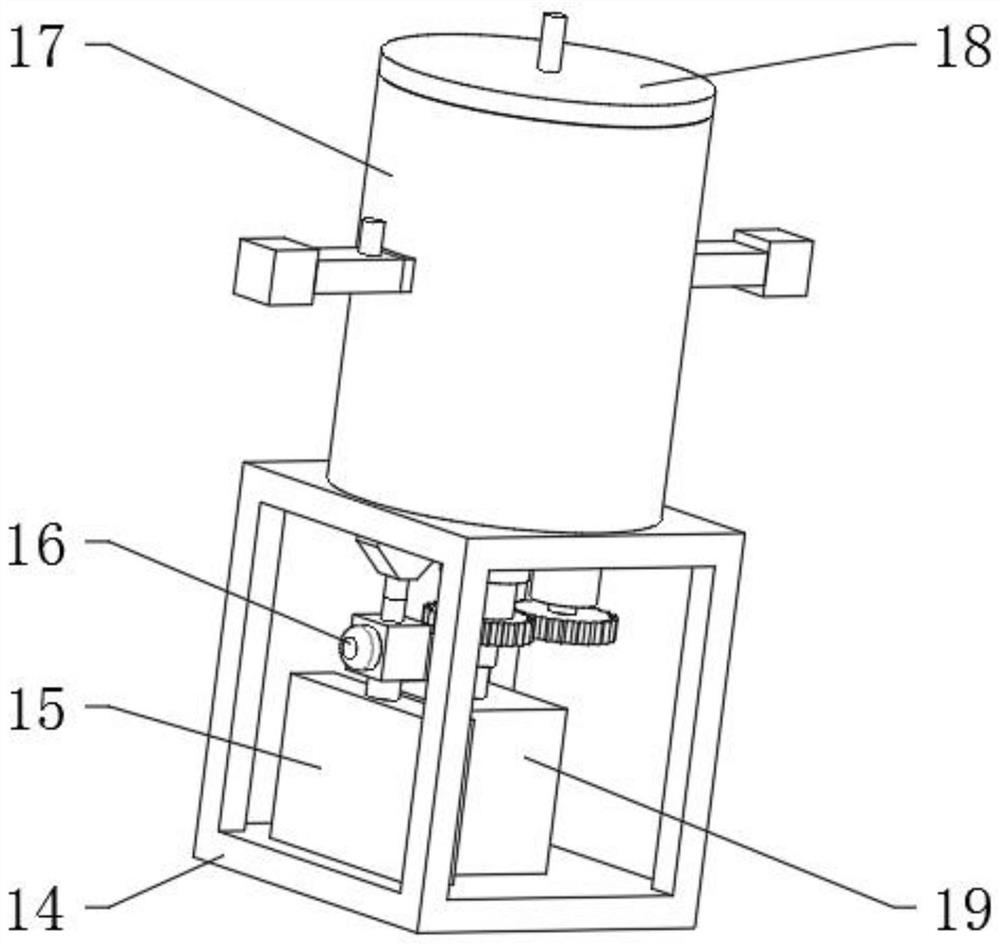

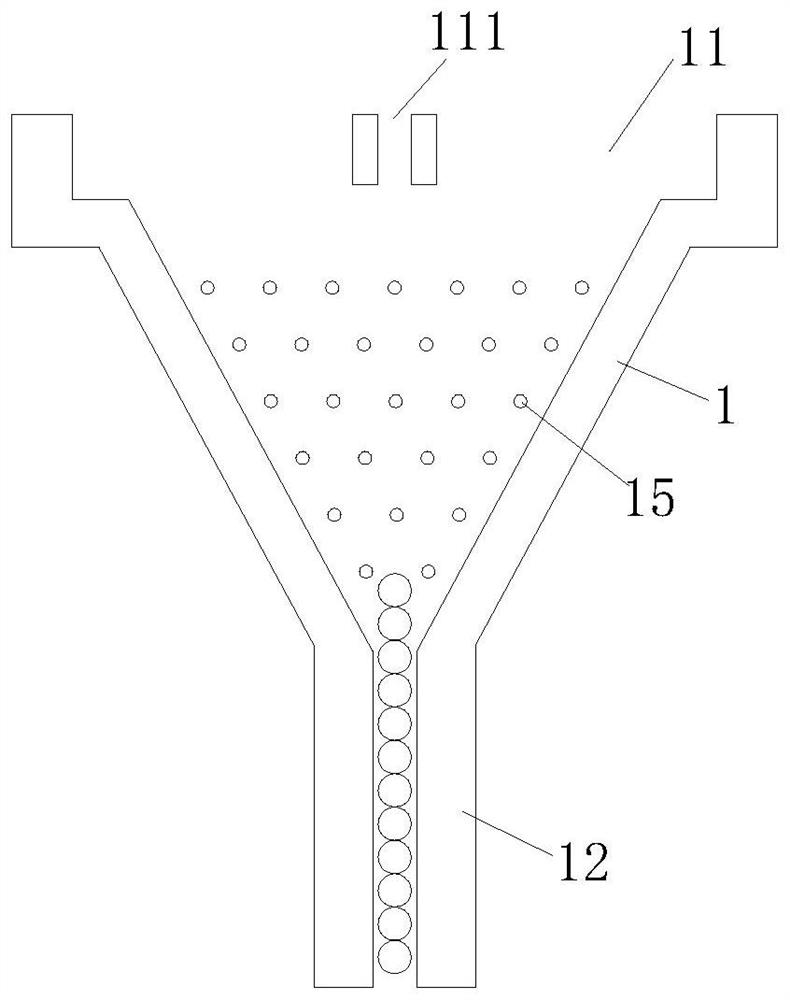

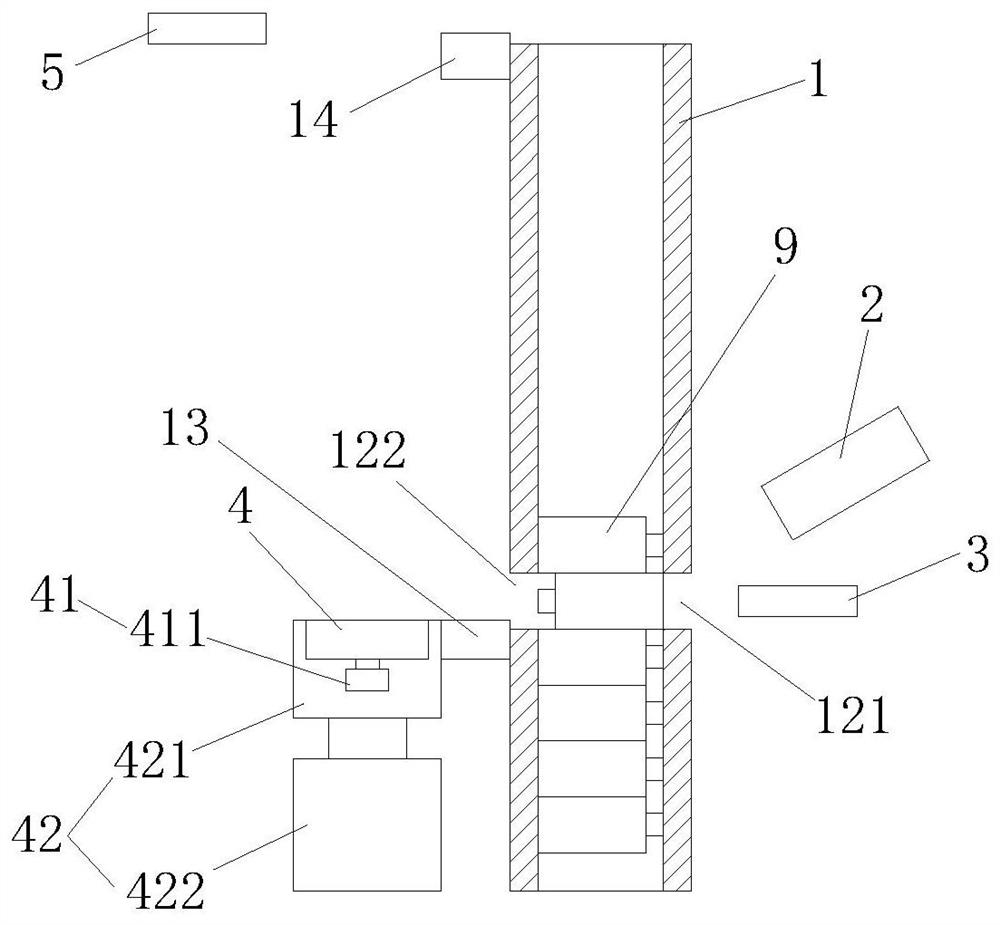

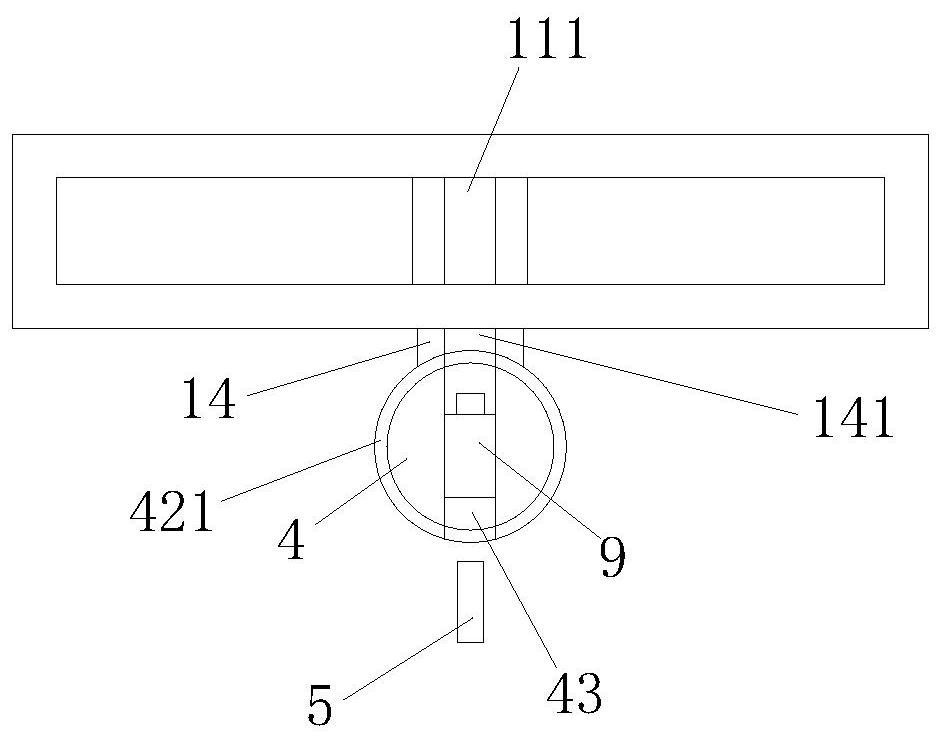

Screening device for lithium battery recycling based on machine vision

The invention discloses a screening device for lithium battery recycling based on machine vision. The screening device comprises a screening box, a feeding hole is formed in the upper end of the screening box, a discharging channel is arranged at the lower end of the screening box, a detection window is arranged on the discharging channel, an industrial camera is arranged on one side of the detection window, an ejection mechanism for pushing lithium batteries with unqualified positions out of the discharging channel is further arranged on one side of the detection window, and a discharging opening for allowing the lithium batteries with unqualified positions to pass through is formed in one side, opposite to the ejection mechanism, of the discharging channel. According to the screening device for lithium battery recycling based on machine vision, the lithium batteries in the discharging channel are visually detected, in cooperation with the ejection mechanism, the lithium batteries with unqualified positions are removed from the discharging channel, and therefore the directions of positive electrodes and negative electrodes of the lithium batteries sent out from the discharging channel are kept consistent, and follow-up recycling treatment is facilitated.

Owner:马鞍山海森控电气有限公司

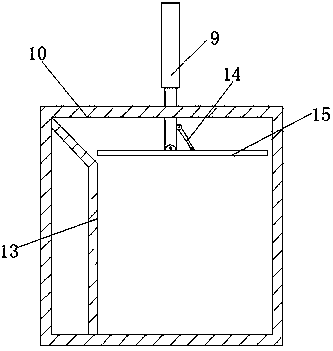

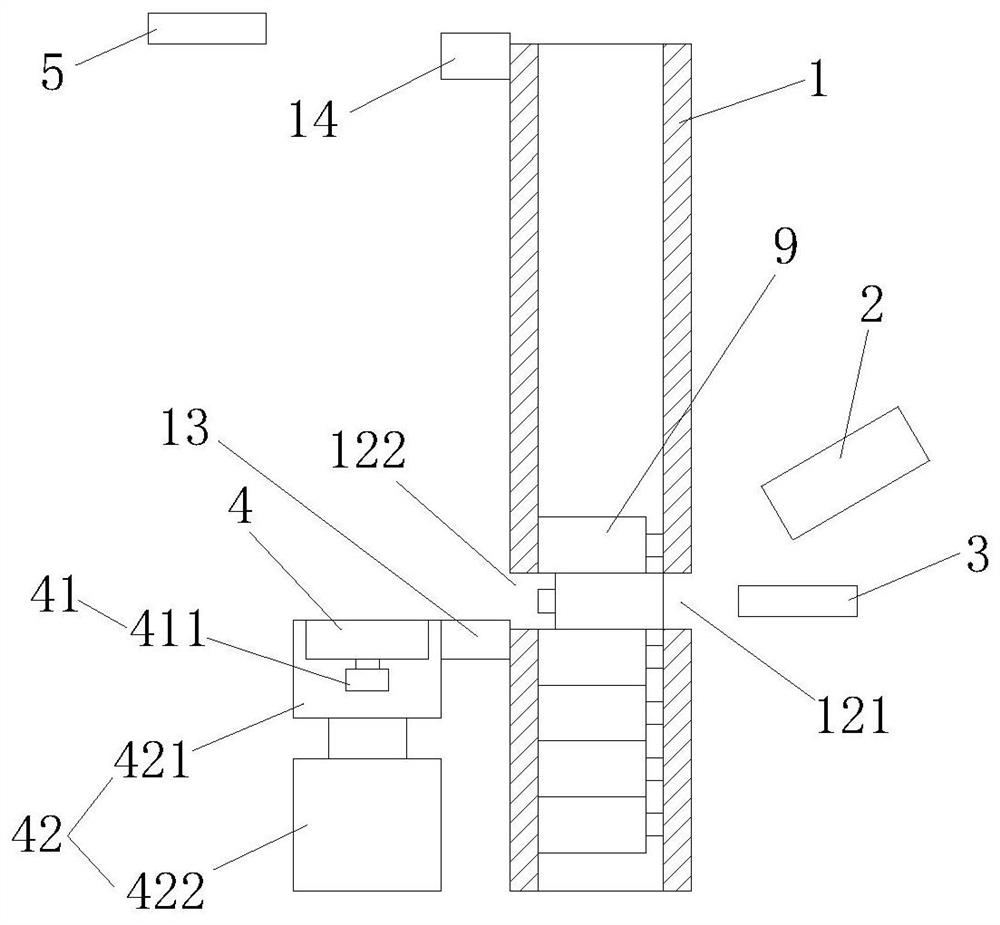

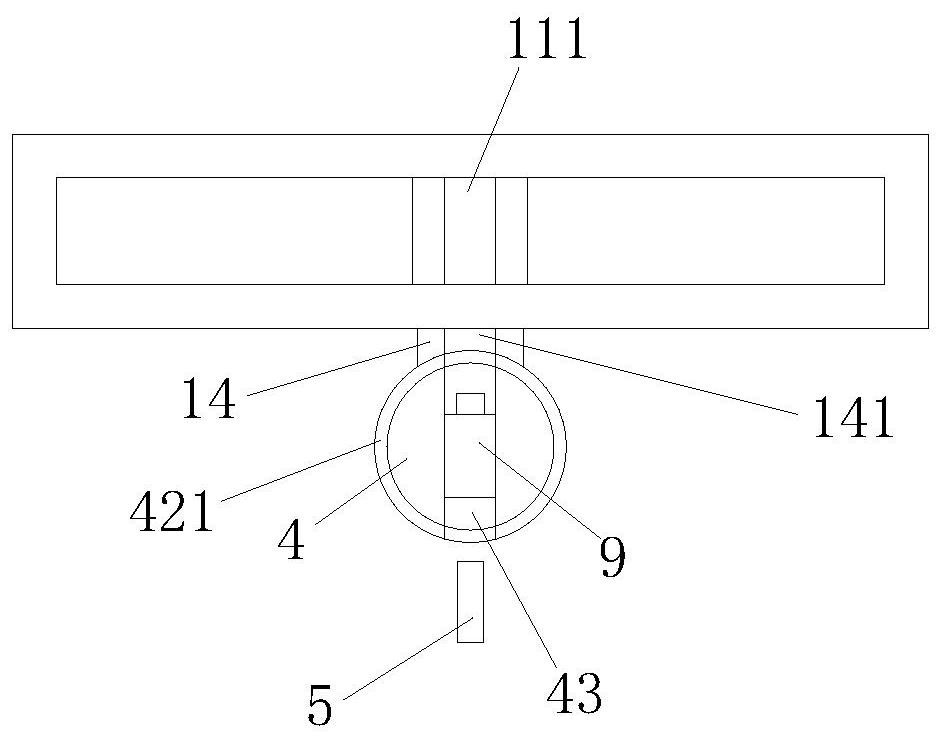

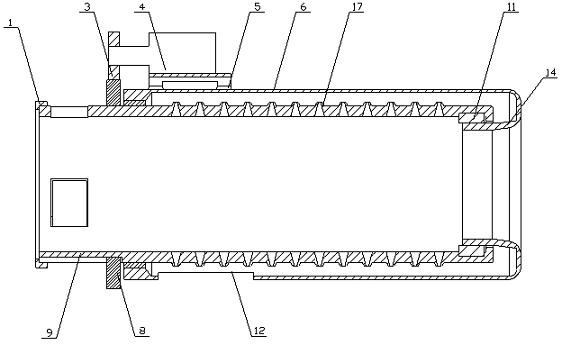

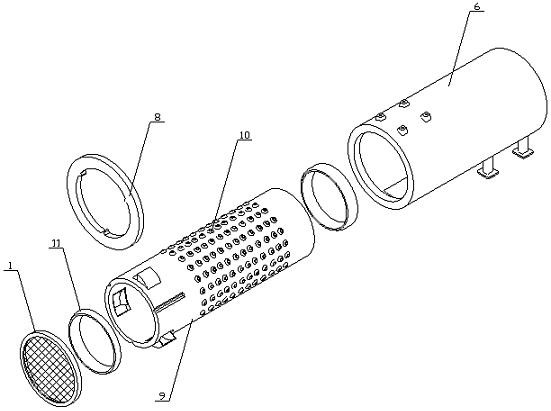

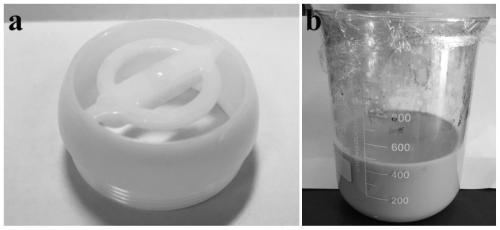

Wastewater introducing structure of sewage treatment system

ActiveCN110448949AAvoid cloggingFacilitate subsequent recyclingTreatment involving filtrationMoving filtering element filtersWastewaterSewage

The invention discloses a wastewater introducing structure of a sewage treatment system. According to the introducing structure, waste in sewage is separated by cooperation of an inner rotary pipe andan outer shell pipe, the waste is pushed to a shield cover through flow assisting pieces, and then the waste is discharged to a solid waste box through a guide shell for storage. The structure is characterized in that the top of the solid waste box has an open structure, one end of the outer shell pipe is placed on the solid waste box, a supporting frame is placed at the bottom of the other end of the outer shell pipe, the supporting frame is composed of an upper part and a lower part, and the two parts are hinged; and the other end of the outer shell pipe is bent reversely towards the interior of the outer shell pipe to form a sewage inlet pipe, one end of the inner rotary pipe is placed in the outer shell pipe and is connected with the sewage inlet pipe through a supporting bearing, theother end of the inner rotary pipe passes out from one end of the outer shell pipe, and the supporting bearing is arranged between the inner rotary pipe and the other end of the outer shell pipe, andthe shield cover is placed on the other end of the inner rotary pipe and is located above an opening of the solid waste box.

Owner:彭素荣

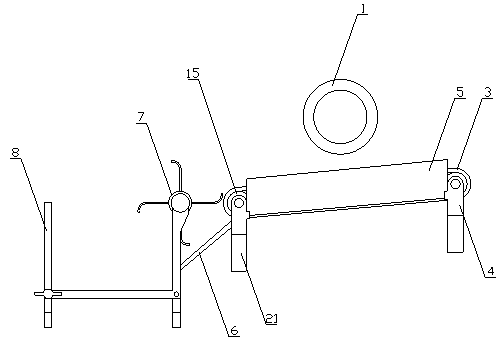

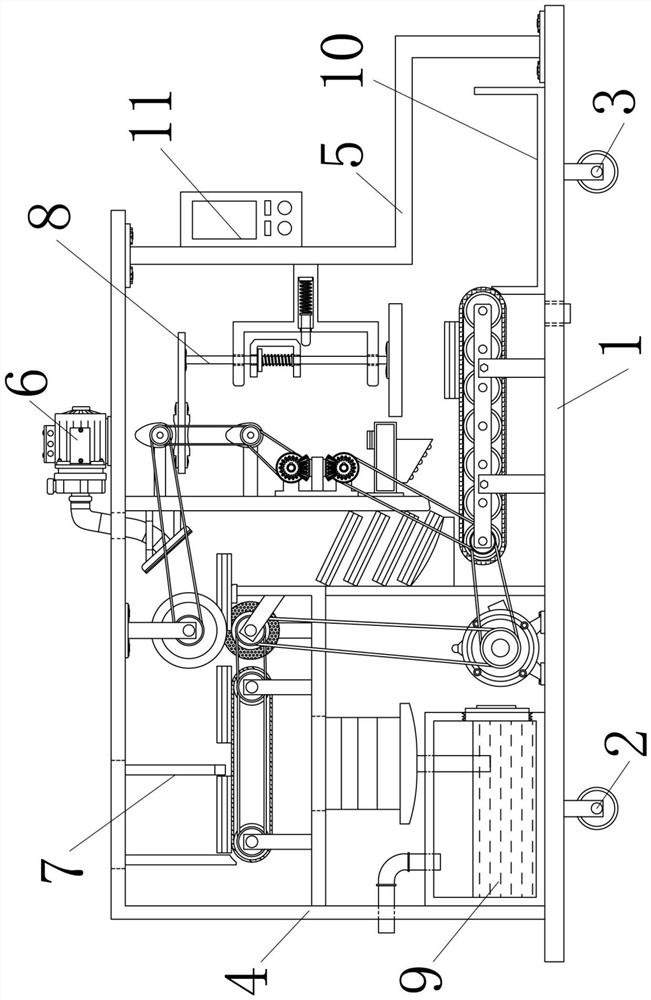

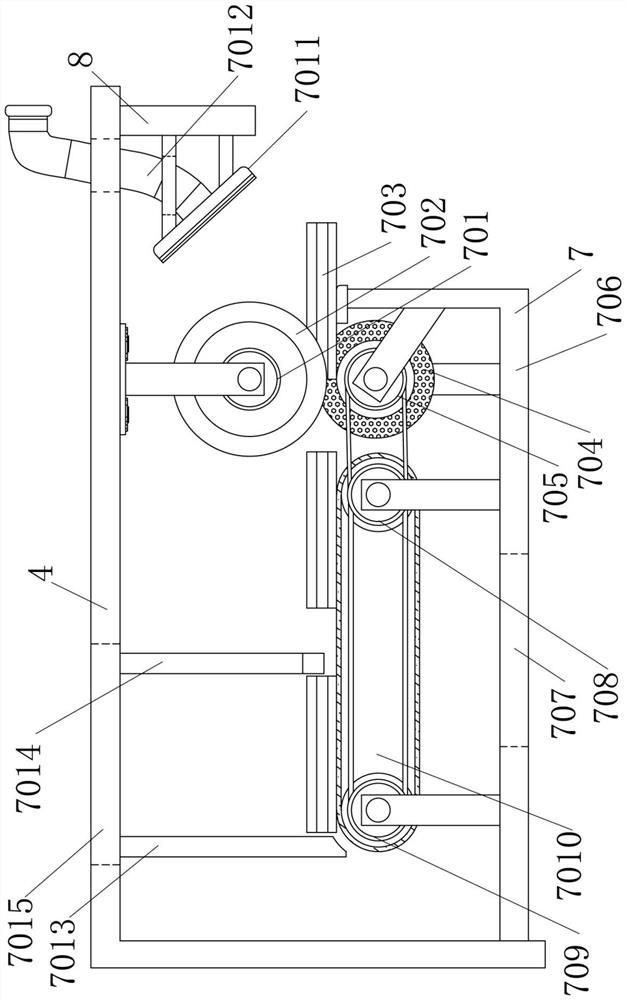

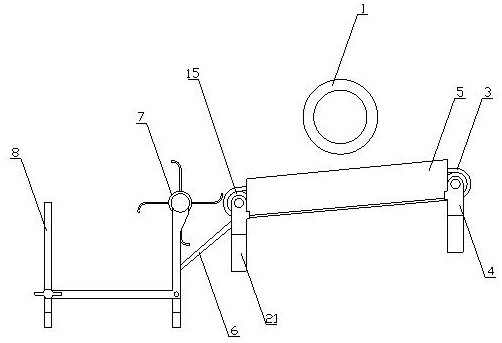

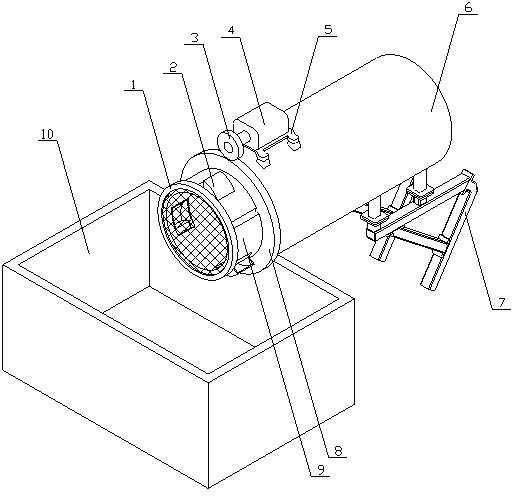

Steel belt cutting and recycling device

The invention relates to the technical field of steel belt recycling, and aims to provide a steel belt cutting and recycling device. The steel belt cutting and recycling device comprises a box body, wherein the box body comprises a collecting device, an extruding device, a rolling device and a cutting device which are sequentially arranged from top to bottom; the collecting device comprises a feeding hopper; an extruding chamber is arranged on the box body and below the feeding hopper; the extruding device comprises an extruder; a sliding pressure plate which is arranged in the extruding chamber in a sliding mode is arranged at the output end of the extruder; the sliding pressure plate is used for dividing the extruding chamber into a left part and a right part; a material outlet is formedin the bottom of the extruding chamber; the rolling device comprises two groups of extruding rollers; the two extruding rollers are positioned below the material outlet; the cutting device comprisesa cutting machine; a cutting knife is arranged on the cutting machine; and the cutting knife is positioned below the extruding rollers. According to the steel belt cutting and recycling device provided by the invention, after rim charges of a steel belt are cut off, the rim charges are collected and then are treated in a centralized mode, so that potential safety hazards caused by rim charge accumulation are prevented, and meanwhile, the rim charges are conveniently recycled.

Owner:温州日正金属材料有限公司

A tile dust-free recycling pretreatment device

ActiveCN111530533BGood for healthFacilitate subsequent recyclingUsing liquid separation agentGrinding machinesAir pumpEnvironmental engineering

The invention relates to a dust-free processing device, in particular to a tile dust-free recycling pretreatment device. The technical problem to be solved by the present invention is to provide a dust-free recovery and pretreatment device for tiles. A tile dust-free recycling pretreatment device, including a bottom plate, a first wheel, a second wheel, a support frame, a first connecting plate, an air pump, an algae removal mechanism, a crushing mechanism, a dust removal mechanism and a collection basket; the bottom end of the bottom plate is left The first wheel is arranged on the upper part; the second wheel is arranged on the right part of the bottom end of the bottom plate. The invention achieves dust-free treatment of tiles, removes the algae on the surface of the tiles and roughly breaks the tiles, which is beneficial to simplify the subsequent process of recycling tiles, and the obtained raw materials do not contain impurities; dust-free treatment avoids the need to process tiles The dust generated when leaving the device will damage the environment and damage the health of the staff and nearby residents.

Owner:三明星硕信息科技有限公司

Utilize metal salt solution to reclaim EDTA metal complex and regenerate the method for chlorine type anion exchange resin

ActiveCN106732832BFacilitate subsequent recyclingOrganic compound preparationIon-exchanger regenerationCadmium CationIon-exchange resin

The invention relates to a method for recycling an EDTA metal complex and regenerating chlorine type anion exchange resin by utilizing a metallic salt solution. The method comprises the following steps: utilizing the chlorine type anion exchange resin to absorb an EDTA cadmium metal complex; taking the chlorine type anion exchange resin loaded with the EDTA cadmium metal complex as a treating object; selecting the metallic salt solution as a regenerating agent; dynamically regenerating the absorbed chlorine type anion exchange resin; treating the regenerated solution; and recycling EDTA and metal cadmium. After the treatment according to the method, the EDTA cadmium metal complex in a complex solution can be effectively recycled, and after the resin is reused for several times, the resin still has a better absorption effect, so that convenience is brought to the future large-scale test, a certain treatment time and cost are reduced, and the secondary pollution to the environment caused by the EDTA metal complex solution can be reduced.

Owner:HUNAN AGRICULTURAL UNIV

Pitching rotating steel bridge for ship lock

ActiveCN112323611BHigh strengthReduce load-bearing deformationBridge structural detailsRoad cleaningMarine engineeringBridge deck

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Method for dissociation of optical recording medium base plate and its film material

InactiveCN100400186CSimple costFacilitate subsequent recyclingSolid waste disposalFilm materialAbsorbed energy

The present invention discloses a method for dissociating optical recording medium base plate and its film material. The optical recording medium is placed in the electromagentic wave environment, the concentrated every of the electromagnetic wave can be used to break the film material layer of optical recording medium, and can make the film material layer absorb energy and quickly be separated from other layer so as to make the base plate material be separated from film material layer.

Owner:FAR EAST COLLEGE

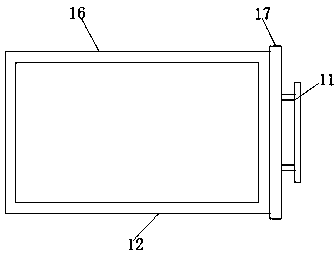

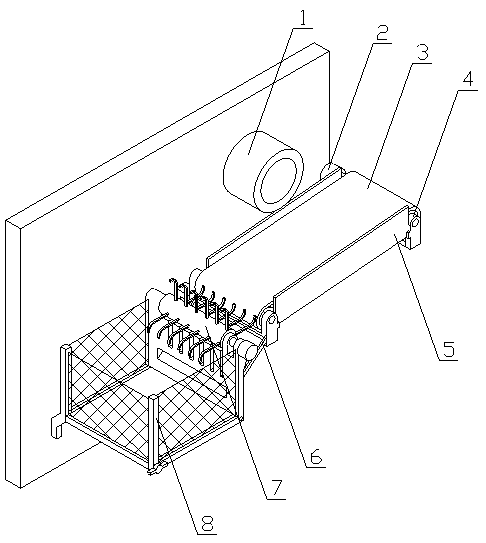

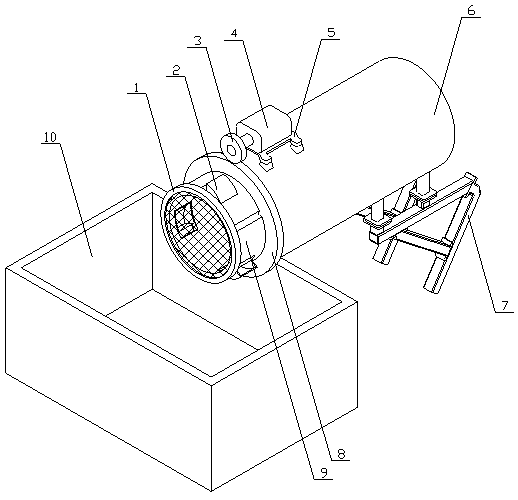

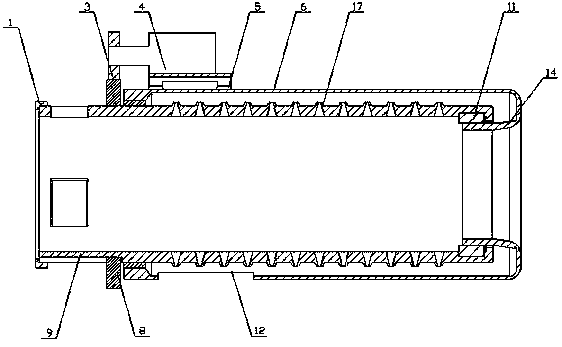

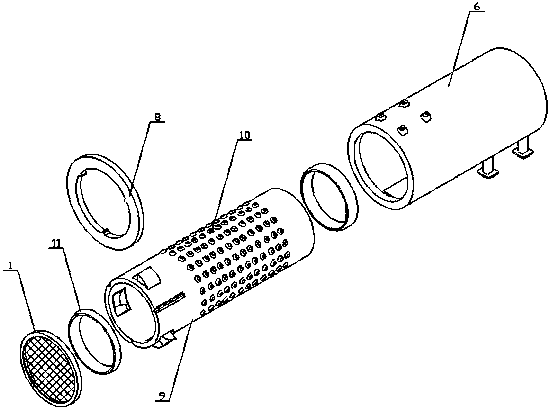

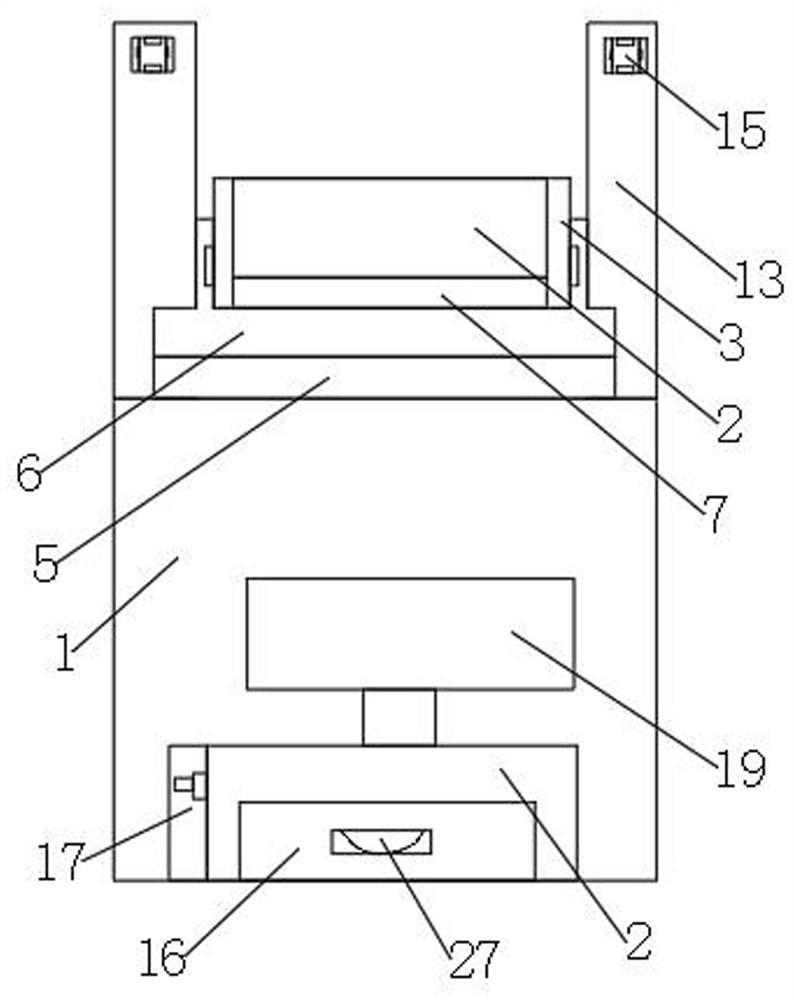

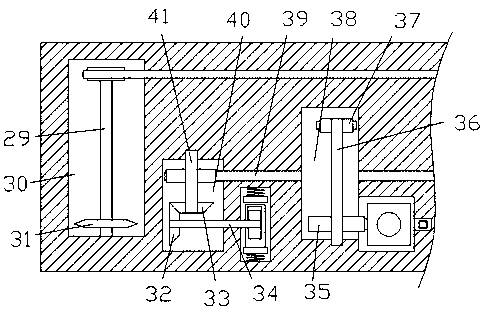

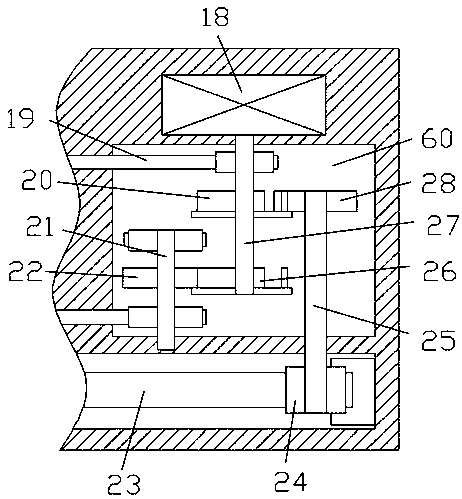

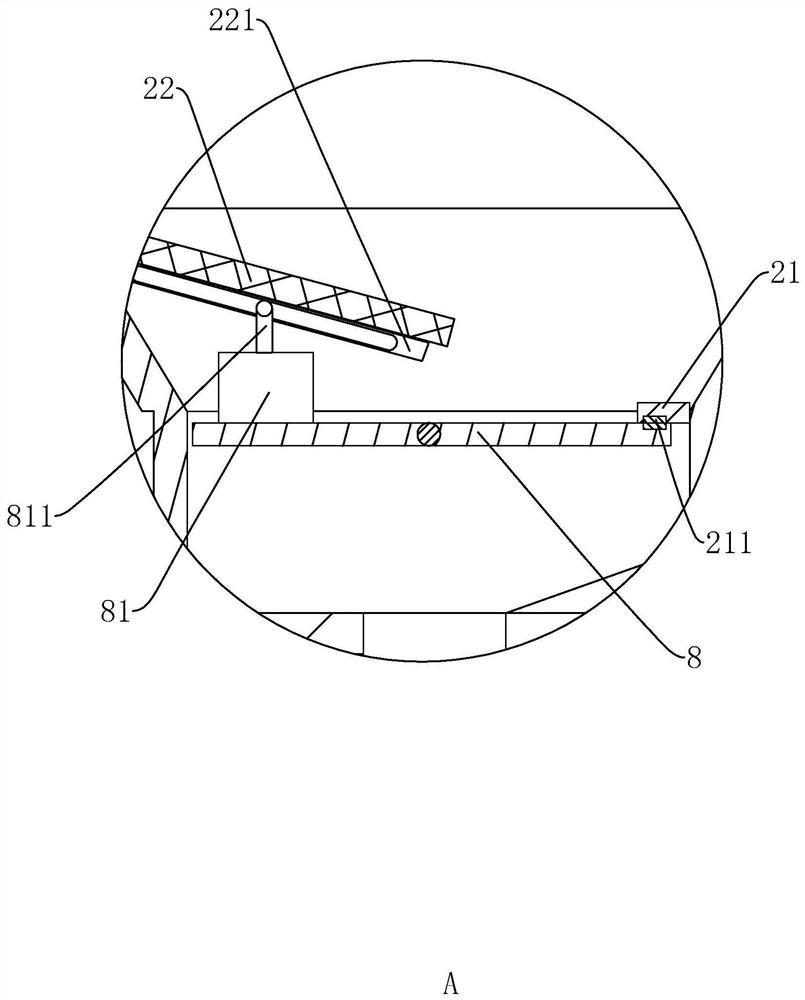

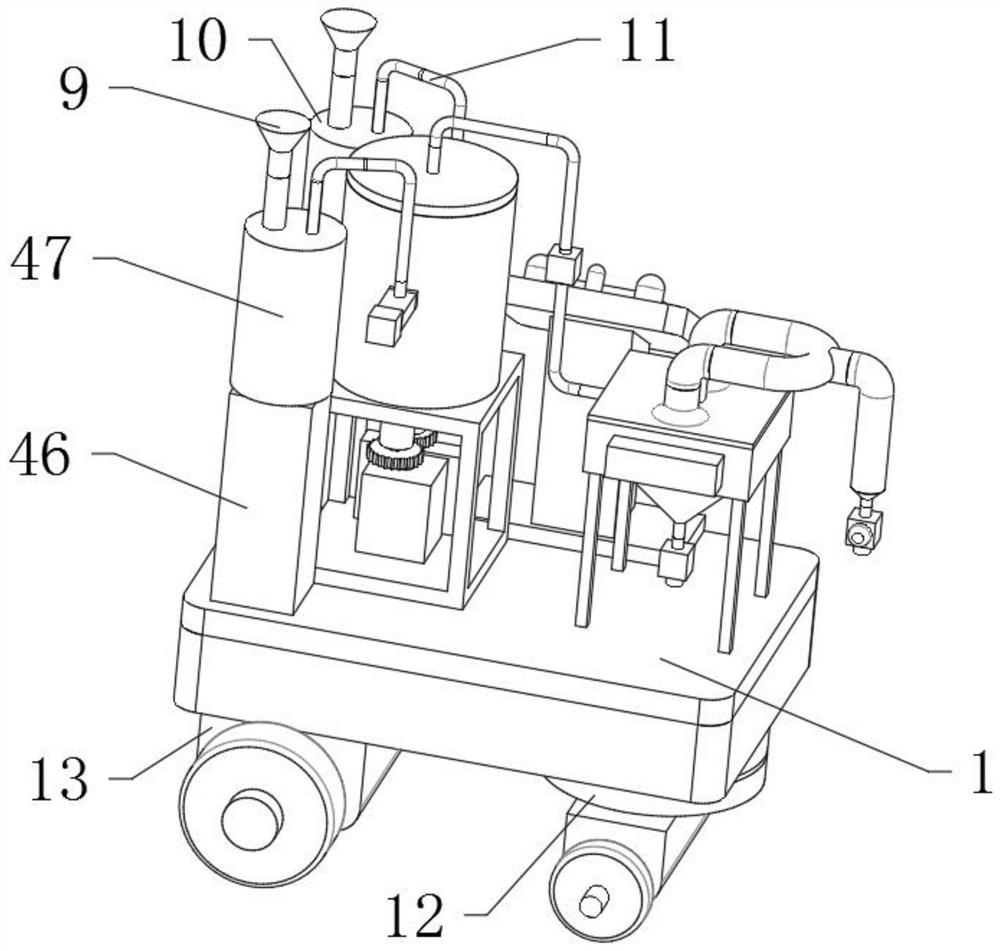

A kind of waste battery recycling pretreatment device

ActiveCN111029678BHealth effectsFacilitate subsequent recyclingReclaiming serviceable partsWaste accumulators reclaimingMetallic enclosureLiquid storage tank

The invention discloses a waste battery recovery pretreatment device, which comprises a main body box, wherein the left end surface of the main body box is fixedly connected with a feeding box, a working cavity extending leftwards into the feeding box is formed in the main body box, the working cavity is opened upwards in the feeding box, the tail end of the right side of the lower end wall of theworking cavity downwards communicates with a metal shell outlet with a downward opening, and a power distribution cavity is formed in the rear side of the working cavity. According to the invention,the pretreatment of a waste battery can be automatically completed by placing the waste battery into a fixed seat, so that the adverse effects of the interior of the battery to the health of an operator are prevented; and the solid-liquid separation of the waste battery is completed through cutting, opening and liquid suction, the mercury-containing liquid is stored in a liquid storage tank, and the metal shell is discharged out of the main body box through the metal shell, so that the subsequent recovery treatment is facilitated while the influence of heavy metals on the external environmentis prevented, and the recycling cost is reduced.

Owner:中创新海(天津)认证服务有限公司

Lathe auxiliary device with functions of workpiece falling prevention and waste treatment

InactiveCN112643399AAffect the filtering effectAvoid scratchesMetal working apparatusMaintainance and safety accessoriesReciprocating motionEngineering

The invention relates to the related field of metal cutting, and discloses a lathe auxiliary device with the functions of workpiece falling prevention and waste treatment. The lathe auxiliary device comprises a main box body, and a working cavity is formed in the main box body; a collecting cavity communicates with the lower end wall of the working cavity, and a filtering cavity communicates with the lower end wall of the collecting cavity; a push plate cavity communicates with the left end wall of the filtering cavity; a cleaning push plate is connected with the interior of the push plate cavity in a sliding fit mode, and a sliding plate cavity is formed in the left side of the push plate cavity; when a workpiece is cut, cutting components in cutting fluid are filtered out through a sieve plate; meanwhile, cuttings remaining on the sieve plate are continuously cleaned through reciprocating motion of the cleaning push plate, and therefore the situation that the sieve plate is blocked and consequently the filtering effect is influenced is avoided; the workload of waste treatment is reduced; the cutting efficiency is improved, and meanwhile the cutting fluid and the cuttings are separated, thereby facilitating subsequent recycling treatment; the production cost is reduced; after a workpiece is cut, a buffer plate is moved so that the workpiece falls onto the buffer plate, and the situation that the workpieces directly falls and is damaged is avoided; and meanwhile, the surface of the workpiece is prevented from being scratched.

Owner:南京晋亿达智能技术有限公司

A method for recycling valuable metals in waste circuit boards

The invention discloses a method for recycling valuable metal in a waste circuit board. The method includes the following steps that the waste circuit board is subject to smashing and reselection to prepare multi-metal powder; a dilute acid solution is added into the multi-metal powder, agitation leaching is carried out, filtering is carried out, and leaching slag I and leaching liquid I are obtained; an acid solution is added into the leaching slag I according to the liquid-solid mass ratio of the acid solution to the leaching slag I being 10-40:1, then an oxidizing agent is added, agitation leaching is carried out, filtering is carried out after leaching is finished, and leaching slag II and leaching liquid II are obtained; the leaching liquid II is subject to cyclone electrodeposition to obtain cathode copper and an after-electrolysis solution; alkali and a reducing agent are added into the leaching slag II, smelting is carried out under the condition that the temperature ranges from 400 DEG C to 600 DEG C, water leaching is carried out, filtering is carried out, and lead bullion containing precious metal and leaching liquid III are obtained; and the leaching liquid III is purified and is subject to evaporation and concentration to obtain a concentrated alkali solution and sodium stannate crystals. According to the method for recycling the valuable metal in the waste circuit board, the procedure is short, the efficiency is high, the cost is low, cleanness is achieved, and pollution is avoided.

Owner:广西自贸区西江资源循环科技产业股份有限公司

Waste battery recovery pretreatment device

ActiveCN111029678AHealth effectsFacilitate subsequent recyclingReclaiming serviceable partsWaste accumulators reclaimingMetallic enclosureLiquid storage tank

The invention discloses a waste battery recovery pretreatment device, which comprises a main body box, wherein the left end surface of the main body box is fixedly connected with a feeding box, a working cavity extending leftwards into the feeding box is formed in the main body box, the working cavity is opened upwards in the feeding box, the tail end of the right side of the lower end wall of theworking cavity downwards communicates with a metal shell outlet with a downward opening, and a power distribution cavity is formed in the rear side of the working cavity. According to the invention,the pretreatment of a waste battery can be automatically completed by placing the waste battery into a fixed seat, so that the adverse effects of the interior of the battery to the health of an operator are prevented; and the solid-liquid separation of the waste battery is completed through cutting, opening and liquid suction, the mercury-containing liquid is stored in a liquid storage tank, and the metal shell is discharged out of the main body box through the metal shell, so that the subsequent recovery treatment is facilitated while the influence of heavy metals on the external environmentis prevented, and the recycling cost is reduced.

Owner:中创新海(天津)认证服务有限公司

A device for filtering solid waste at river channel sewage outlet

ActiveCN110565770BEasy to cleanAvoid cloggingFatty/oily/floating substances removal devicesSewerage structuresAgricultural engineeringSewage outfall

Owner:徐州中知知识产权服务有限公司

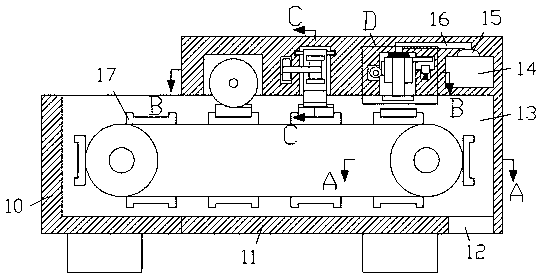

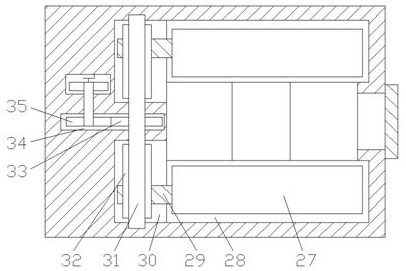

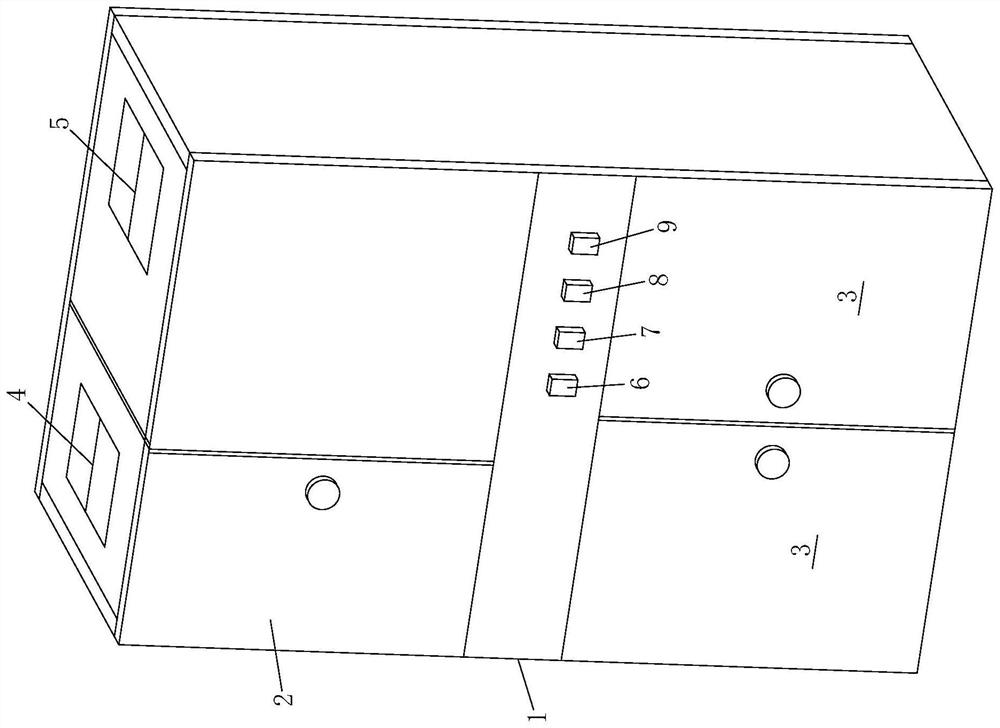

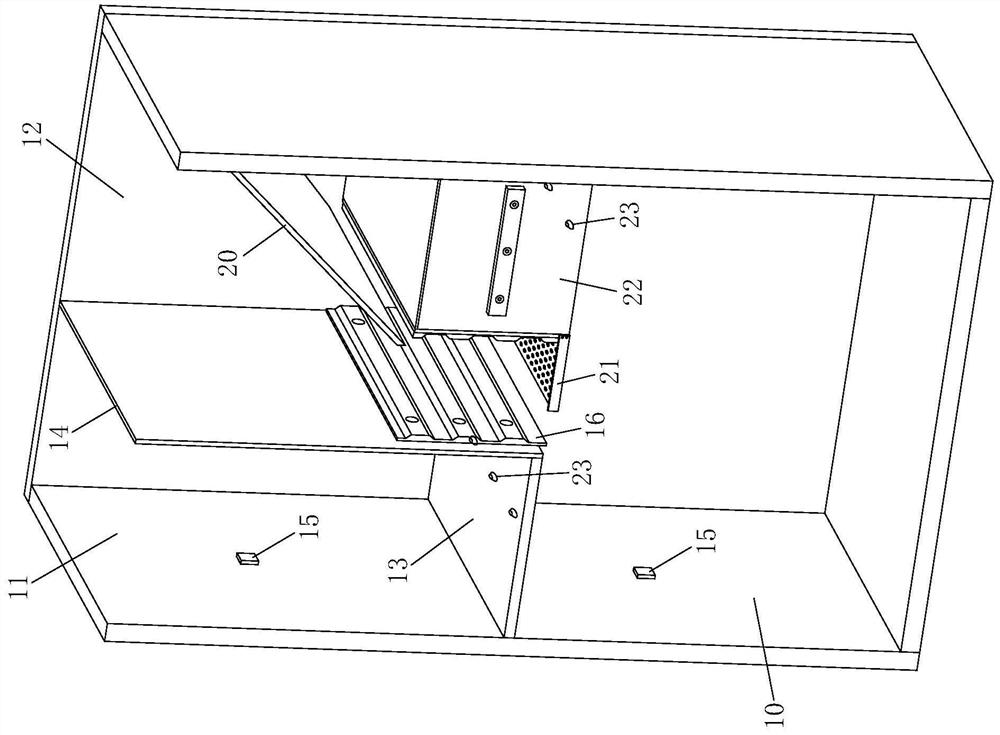

Paper cup and paper box recycling machine

ActiveCN114671158AEasy to recycleReduce workloadRefuse receptaclesRefuse cleaningManufacturing engineeringIndustrial engineering

A paper cup and paper box recycling machine is characterized in that a transverse partition plate and a vertical partition plate are arranged in a cabinet, an inner cavity of the cabinet is divided into a plastic part collecting box, a paper part collecting box and a paper part storage box by the transverse partition plate and the vertical partition plate, and a top panel of the cabinet is provided with a plastic part feeding port and a paper part feeding port corresponding to the plastic part collecting box and the paper part collecting box; a front panel of the cabinet is provided with a single door and a double door corresponding to the plastic part collection box and the paper part storage box; a paper flattening device is arranged at the bottom of the paper collecting box and comprises a static pressure plate and a movable pressing plate assembly, the static pressure plate is arranged on the lower portion of the vertical partition plate, the movable pressing plate assembly comprises an installation box fixed to the inner wall of the cabinet, a sliding rail is arranged on a side panel of the installation box, a sliding rod is arranged on the sliding rail in a sliding fit mode, and the front end of the sliding rod is fixed to a bearing plate. A movable pressing plate right facing the static pressing plate is arranged on the front side face of the bearing plate, and a driving mechanism of the movable pressing plate is arranged in the mounting box. The paper cup and paper box flattening and compacting device facilitates follow-up recycling treatment, reduces the workload, flattens and compacts paper cup and paper boxes conveniently, saves the storage space and facilitates environment cleaning.

Owner:浙江庞度环保科技股份有限公司

A waste textile processing device

ActiveCN109304234BLimit the range of rotationLarge rotationCleaning using toolsGrain treatmentsForeign matterIndustrial engineering

The invention discloses a device for treating waste textiles, which includes a crushing box, a feeding mechanism, a crushing mechanism, a screening mechanism and a recycling mechanism. The crushing mechanism includes two intermeshing crushing rollers located in the crushing box and a device that drives the crushing rollers to rotate. Driving component, the screening mechanism is located below the crushing roller. The screening mechanism includes an air selection component, a separation component for separating textiles, and a collection component for collecting textiles. The present invention can use the winnowing component to remove the particles in the crushed textiles. Foreign matter is separated to facilitate the subsequent recycling of waste textiles.

Owner:安徽智时代科技有限公司

A steel strip cutting recovery device

The invention relates to the technical field of steel strip recycling, and aims to provide a steel strip cutting and recycling device, which includes a box body, and the box body includes a collection device, an extrusion device, a rolling device, and a cutting device arranged sequentially from top to bottom , the collection device includes a feed hopper; the box body is provided with an extrusion chamber below the feed hopper, the extrusion device includes an extruder, and the output end of the extruder is provided with a sliding device arranged on the extruder The sliding pressing plate in the pressing chamber, the sliding pressing plate divides the pressing chamber into left and right parts, and the bottom of the pressing chamber is provided with a material outlet; the rolling device includes two sets of squeezing rollers, Located below the material outlet; the cutting device includes a cutting machine, the cutting machine is provided with a cutting knife, and the cutting knife is located below the extrusion roller; the present invention collects the edge material after the edge material of the steel strip is cut off The centralized treatment prevents the potential safety hazards caused by the accumulation of side materials, and at the same time facilitates the recycling of side materials.

Owner:温州日正金属材料有限公司

Fluorine adsorption material as well as preparation method and application thereof

PendingCN113893827AHigh selectivityImprove adsorption capacityOther chemical processesWater contaminantsCarboxylic acidSilica gel

The invention provides a fluorine adsorption material and a preparation method and application thereof. The preparation method comprises the following steps: (1) activating silica gel, mixing the activated silica gel with an organic solution of amino silane, and conducting reacting to obtain amino silane modified silica gel; and (2) carrying out acidification reaction on the amino silane modified silica gel and polycarboxylic acid in an acidic solution, adding a metal mixture to carry out chelation reaction, and carrying out alkali liquor treatment to obtain the fluorine adsorption material. The fluorine adsorption material is an adsorbent with high adsorption capacity, high selectivity, easy regeneration capacity and high cyclicity, and can be effectively used for treating fluorine-containing wastewater.

Owner:JIANGSU HELPER FUNCTIONAL MATERIALS

A sewage treatment system wastewater introduction structure

ActiveCN110448949BAvoid cloggingFacilitate subsequent recyclingTreatment involving filtrationMoving filtering element filtersWater treatment systemWastewater

A waste water introduction structure of a sewage treatment system disclosed in the present invention discloses a method of isolating garbage in sewage through the cooperation of the inner spiral pipe and the outer shell pipe, and pushes the waste to the baffle through the auxiliary flow sheet, and then discharges it to the solid state through the guide shell. The introduction structure for storage in the dustbin is characterized in that the top of the solid waste bin is an open structure, one end of the shell pipe is placed on the solid waste bin, and the support frame is placed at the bottom of the other end of the shell pipe, and the support frame is composed of The upper and lower parts are composed of two parts, and the two parts are hinged. The other end of the outer casing pipe is reversely bent into the outer casing pipe to form a sewage inlet pipe. One end of the inner spiral pipe is placed in the outer casing pipe and connected to the sewage inlet pipe through a support bearing. , the other end of the inner spiral tube passes through one end of the outer shell tube, a support bearing is placed between the inner spiral tube and the other end of the outer shell tube, the shield is placed on the other end of the inner spiral tube, and is located at the mouth of the solid waste bin above.

Owner:彭素荣

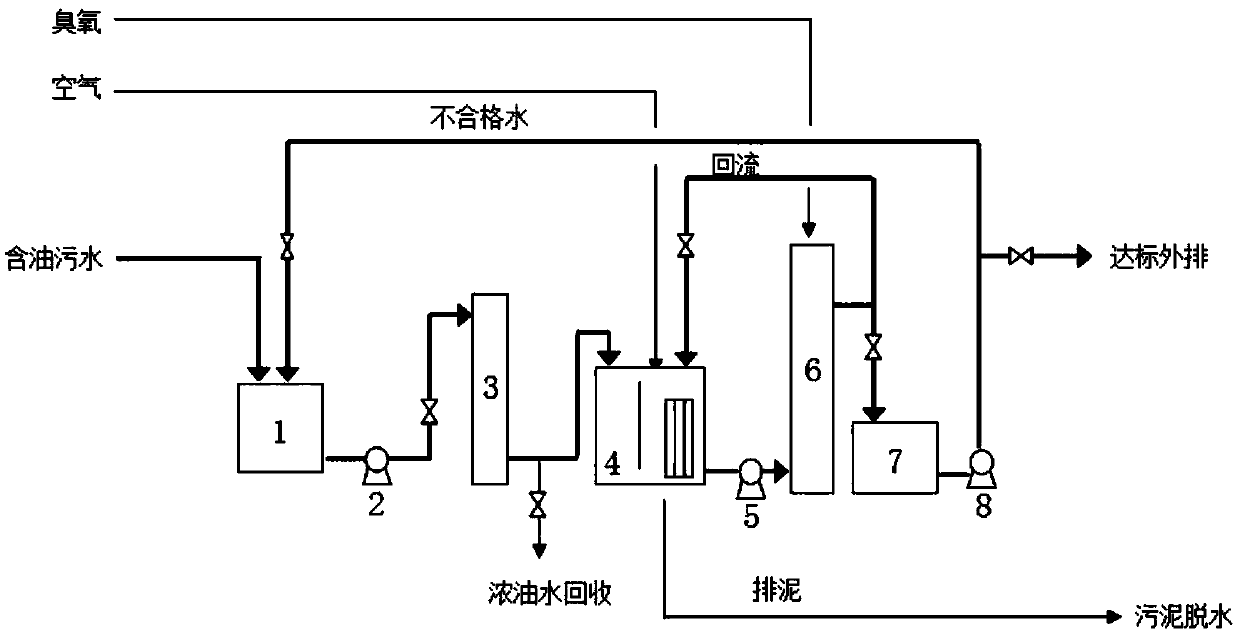

Finished oil depot sewage treatment system and sewage treatment method thereof

InactiveCN108033636ARemove comprehensivelyEfficient removalWater contaminantsTreatment involving filtrationTherapeutic effectPetroleum

The invention discloses a finished oil depot sewage treatment system and a sewage treatment method thereof. The finished oil depot sewage treatment system comprises a regulating reservoir and a ceramic-based functional membrane device which are connected, wherein a water inlet of the regulating reservoir is connected with oily sewage; a water outlet of the ceramic-based functional membrane deviceis respectively connected with a thick oily water recovery device and an integrated membrane bio-reactor; the integrated membrane bio-reactor is provided with an air inlet connected with air and a sludge outlet connected with a sludge dewatering device; a water outlet of the integrated membrane bio-reactor is connected with a catalytic ozonation tower; the catalytic ozonation tower is provided with an ozone inlet connected with ozone; a water outlet of the catalytic ozonation tower is respectively connected a reflux inlet of the integrated membrane bio-reactor and a clean water basin; and a water outlet of the clean water basin is respectively connected with a water return inlet of the regulating reservoir and a clean water discharge pipeline. The finished oil depot sewage treatment systemand the sewage treatment method thereof disclosed by the invention have the advantages of effectively removing petroleum and COD pollutants, enhancing the treatment effect, realizing up-to-standard discharge of oil-gas depot sewage, and facilitating recovery of thick oil.

Owner:CNOOC ENERGY TECH & SERVICES +2

A surface treatment method for abs plastic electroplating

The invention discloses a surface treatment method for ABS plastic electroplating. A one-step swelling-coating graphene oxide secondary-reduction process is adopted; a uniform and continuous conductive layer is directly formed on the surface of an ABS product; the using of heavy metal salts and precious metals is avoided, the technical process and cost are largely reduced; the surface treatment method is simple and efficient and is easy to perform; the operability is high, the cost is low, and the surface treatment method is suitable for industrial large-scale production and application and has an important application value.

Owner:HUAQIAO UNIVERSITY +1

A conductive surface treatment method before electroplating of abs plastics

The invention discloses a conductive surface treatment method before electroplating of ABS plastics, which uses the excellent conductivity and film-forming properties of graphene microchips to directly coat graphene coatings on the surface of plastic products by certain means to endow insulating ABS. Plastic surfaces have a certain conductivity. The ABS plastic coated with a graphene conductive layer on the surface prepared by the method of the present invention can be directly electroplated, which saves complex and cumbersome procedures such as roughening, sensitization, activation, and chemical plating in the traditional process, and is safer, more environmentally friendly, The method is simple and easy, and greatly shortens the technological process and cost, and is suitable for industrialized electroplating of ABS plastics of different shapes and sizes, and has important practical application value. The graphene conductive layer coated on the ABS plastic surface by the method of the invention is uniform and continuous, has good adhesion, and can be directly electroplated.

Owner:HUAQIAO UNIVERSITY +1

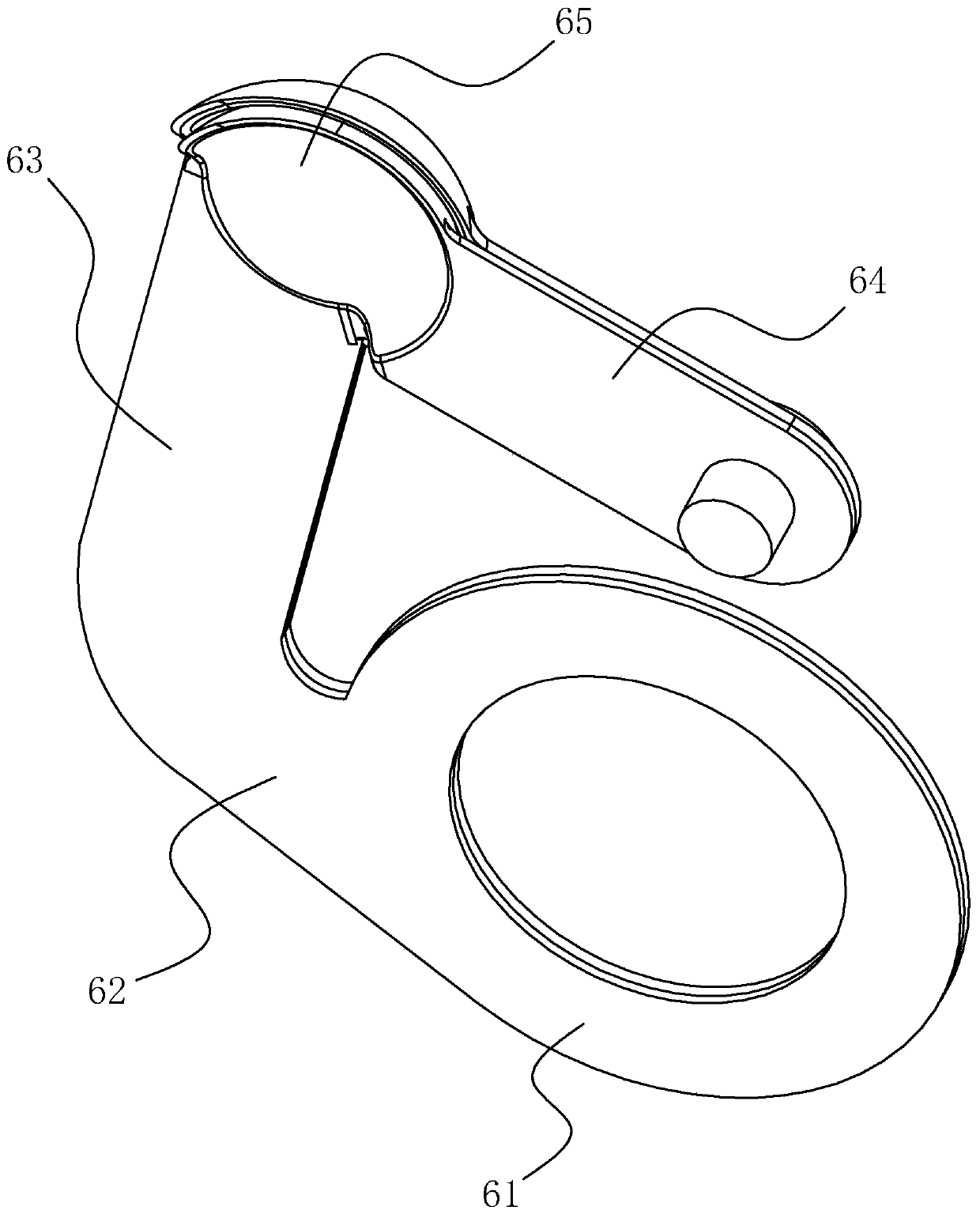

A thermostat safety device

ActiveCN109216110BAchieve meltingGuaranteed cooperationHeating/cooling contact switchesThermal switch detailsTemperature controlThermostat

The invention discloses a temperature control safety device, A thermosensitive switching device the technical scheme mainly comprises an upper fuse plate and a lower fuse plate fixed on an insulatingring frame of the thermostat and connected with a temperature control device of the thermostat, and a fixing piece fixed to the lower end of the insulating ring frame and a stopper, wherein the stopper comprises a thermally conductive metal sleeve clamped to the fixing sheet and provided with an upper end opening, a hot melt filled in the heat conductive metal sleeve and a jacking rod inserted inthe heat conductive metal sleeve for jacking the lower fuse and the upper fuse, wherein the bottom end part of the heat conductive metal sleeve is communicated with the outside of the heat conductivemetal sleeve, and the bottom end of the stopper is in contact with the electric heating work piece; The temperature control safety device has the effect of convenient installation and fixation.

Owner:厦门升明电子有限公司

Movable simple water purifying device for decentralized domestic sewage

InactiveCN112875958AEasy to useFacilitate subsequent recyclingTreatment involving filtrationMultistage water/sewage treatmentSewageSewage treatment

The invention discloses a movable simple water purifying device for decentralized domestic sewage, and relates to the technical field of sewage treatment. The problem that water body filtering dirt cannot be discharged in time is solved. The device specifically comprises a bottom plate, a distillation assembly and a purification assembly are fixedly connected to the outer wall of the top of the bottom plate, a filtering assembly is arranged in the purification assembly, and the purification assembly comprises a frame and a generation cylinder. By arranging the purification assembly and the filtering assembly, a lifting air cylinder is started, a middle shaft is contracted and pulled back, the filtering assembly is driven to descend along a generation barrel, after reaction liquid medicine is added and stands, water in the generation barrel fully reacts, dirt and floating objects are generated, and the filtering assembly descends to separate and clean the water and the dirt; and dirt can be piled into the lower portion of the generation cylinder, follow-up recycling treatment is facilitated, furthermore, a cross plate can rotate to drive a brush plate to clean the filtering assembly, and it can be guaranteed that the filtering assembly is used for a long time.

Owner:夏维坤

Screening device for lithium battery recycling based on machine vision

The invention discloses a screening device for recycling lithium batteries based on machine vision, which comprises a screening box; a feeding port is arranged at the upper end of the screening box; a discharge channel is provided at the lower end of the screening box; Detection window; one side of the detection window is provided with an industrial camera; one side of the detection window is also provided with an ejection mechanism that pushes the unqualified lithium battery out of the discharge channel; the discharge channel is in contact with the ejector On the opposite side of the mechanism, there is a discharge port for the passage of unqualified lithium batteries. The screening device for recycling lithium batteries based on machine vision of the present invention uses visual detection of lithium batteries in the discharge channel and cooperates with the ejection mechanism to remove unqualified lithium batteries from the discharge channel, so that the lithium batteries in the discharge channel can be removed from the discharge channel. The direction of the positive and negative poles of the lithium batteries sent out by the channel is consistent, which is convenient for subsequent recycling.

Owner:马鞍山海森控电气有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com