River channel sewage outlet solid waste filtering device

A sewage outlet and garbage technology, which is applied in the direction of sewage removal, water supply device, grease/oily substance/float removal device, etc., can solve problems such as pipeline blockage, failure to be discharged in time, affecting the interception effect of solid waste in sewage, etc. The effect of avoiding accumulation and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

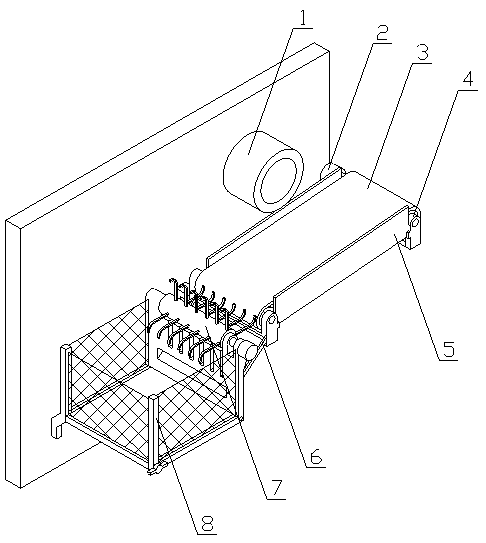

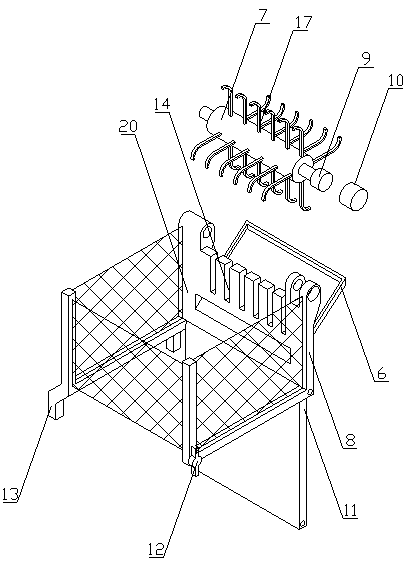

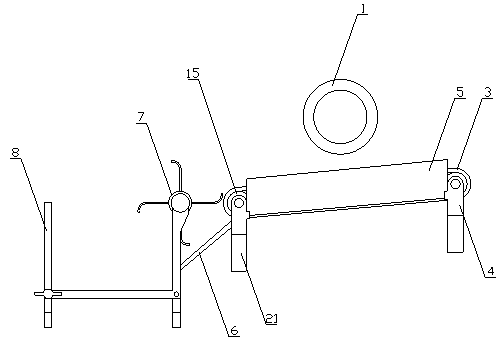

Embodiment 1

[0026]A solid waste filtering device for a river sewage outlet of the present invention is realized in the following way: a solid garbage filtering device for a river sewage outlet of the present invention consists of a conveyor belt (3), a motor (2), a conveyor belt (3), and a fixing frame (4 ), baffle (5), inclined plate (6), separation roller (7), garbage storage basket (8), separation roller motor (9), motor fixing case (10), bottom plate (11), lock valve ( 12), fixed seat (13), avoidance groove (14), conveying wheel (15), filter screen (16), hook claw (17), fixed plate (20) and connecting seat (21), two fixed The frame (4) is respectively placed on the two ends of the connecting seat (21), and the two conveying wheels (15) are respectively placed on the two fixed frames (4), and the two ends of the shaft on the conveying wheel (15) pass through the bearing It is connected with the fixed frame (4), and the two conveying wheels (15) are connected by a conveying belt (3). Th...

Embodiment 2

[0031] The difference between this embodiment and Embodiment 1 is that: a retaining net (18) is placed between two adjacent claws (17) in the same group on the separation roller (7); when in use, the retaining net (18) It can prevent solid waste from falling when the separation roller (7) is hooked up;

Embodiment 3

[0033] The difference between this embodiment and Embodiment 1 is: the hook (17) is equipped with a plurality of triangular teeth (19) equidistantly, and the width of the triangular teeth (19) gradually increases from top to bottom; when in use, The triangular teeth (19) increase the contact area with the solid waste and improve the hooking force;

[0034] The present invention also relates to an adaptive adjustment method for garbage transfer speed, which is characterized in that it includes the following steps: A. The flowmeter reads the sewage flow information in the sewage pipe (1); B. The signal converter converts After the data detected by the flowmeter is converted, it is sent to the data processor that has established a communication connection with itself, and the data processor performs data judgment according to the judgment rules, and performs data interaction with the controller. The flow detection data is verified according to the judgment rule, and step C is exe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com