Wastewater introducing structure of sewage treatment system

A sewage treatment system and wastewater technology, applied in water/sewage treatment, water/sludge/sewage treatment, filtration treatment, etc., can solve the problems of solid waste backlog, pipeline blockage, soil damage, etc. Easy to install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

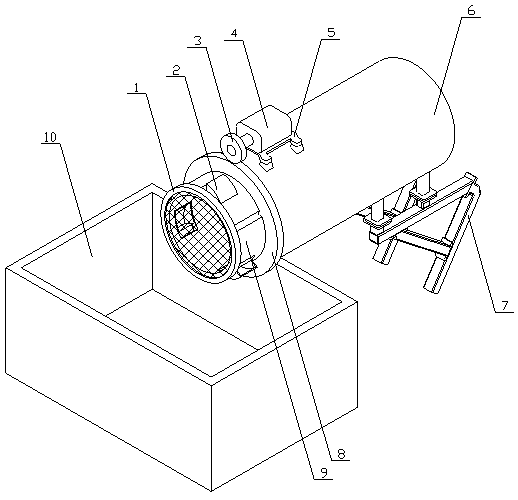

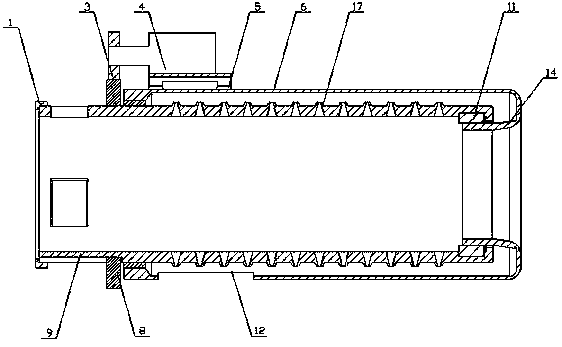

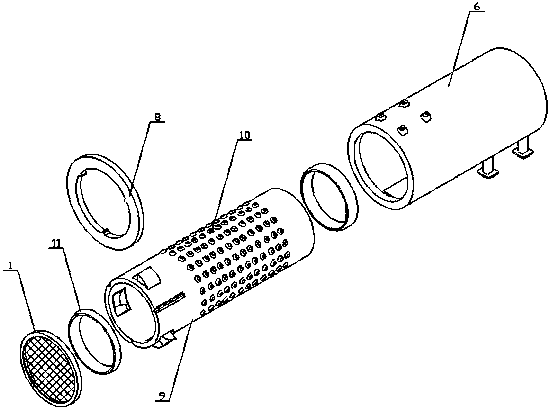

[0029] A waste water introduction structure of a sewage treatment system in the present invention is realized in the following way: a waste water introduction structure of a sewage treatment system in the present invention consists of a baffle (1), a guide shell (2), a drive gear (3), a motor (4), and a fixed Seat (5), shell pipe (6), support frame (7), driven gear (8), inner spiral pipe (9), solid waste bin (10), support bearing (11), drainage groove (12), It is composed of torsion spring (13), sewage inlet pipe (14), auxiliary flow plate (15), groove (16) and water hole (17). The top of the solid waste bin (10) is an open structure, and the outer shell One end of the pipe (6) is placed on the solid waste bin (10), and the support frame (7) is placed at the bottom of the other end of the shell pipe (6). The support frame (7) is composed of upper and lower parts, and the two parts are connected to each other Hinged, the other end of the shell tube (6) is reversely bent into th...

Embodiment 2

[0033] The difference between this embodiment and Embodiment 1 is: the guide shell (2) is a fan-shaped structure, and the guide shell (2) is provided with a garbage discharge port (18) facing the solid waste bin (10); , the garbage outlet (18) of the fan-shaped guide shell (2) is larger, which is convenient for garbage discharge, and the garbage outlet (18) faces the solid garbage bin (10), so that the garbage can be discharged directly along the garbage outlet under the action of centrifugal force In the solid waste bin (10), avoid discharge from other directions and fly away;

[0034] The present invention also relates to a self-adaptive adjustment method of the garbage conveying speed of the inner spiral pipe (9), which is characterized in that it comprises the following steps:

[0035] A. The flowmeter reads the sewage flow information in the sewage pipe;

[0036] B. The signal converter converts the data detected by the flowmeter and sends it to the data processor that h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com