High efficiency flue gas purification device

A flue gas purification and high-efficiency technology, applied in gas treatment, electrostatic effect separation, chemical instruments and methods, etc., can solve problems such as air pollution, destruction of ecological balance, and human injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

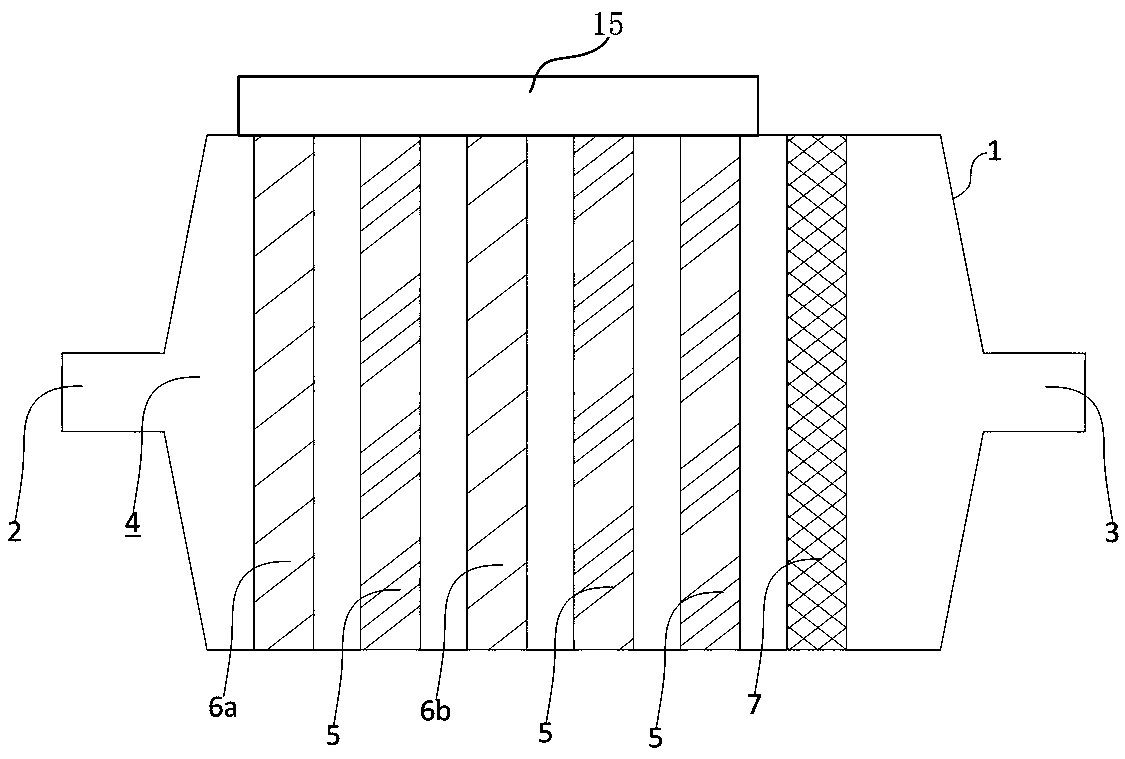

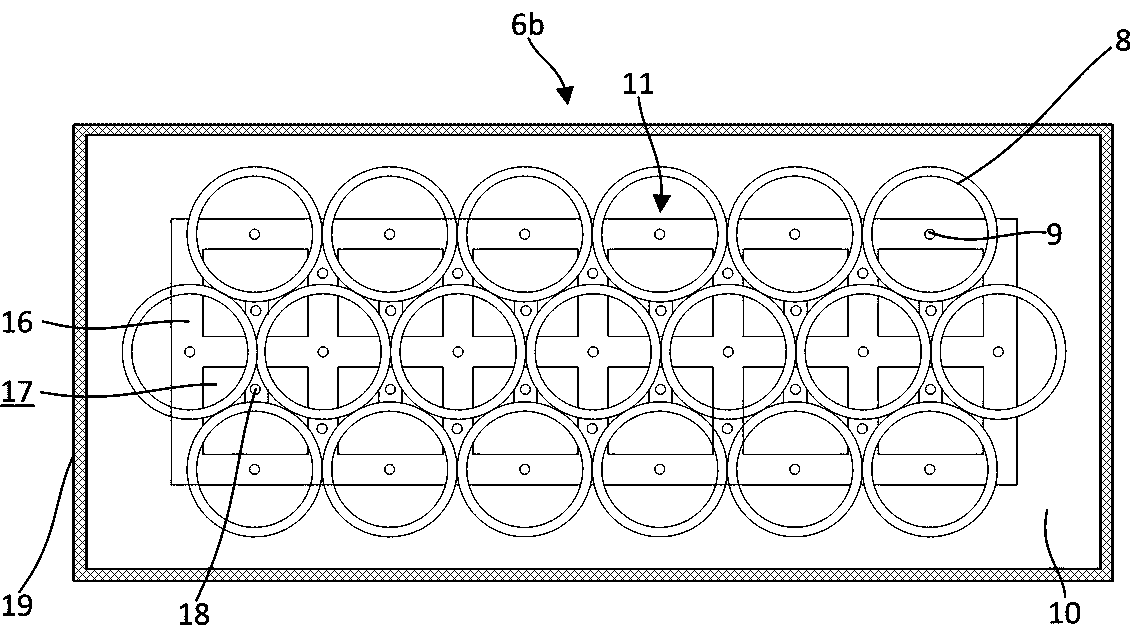

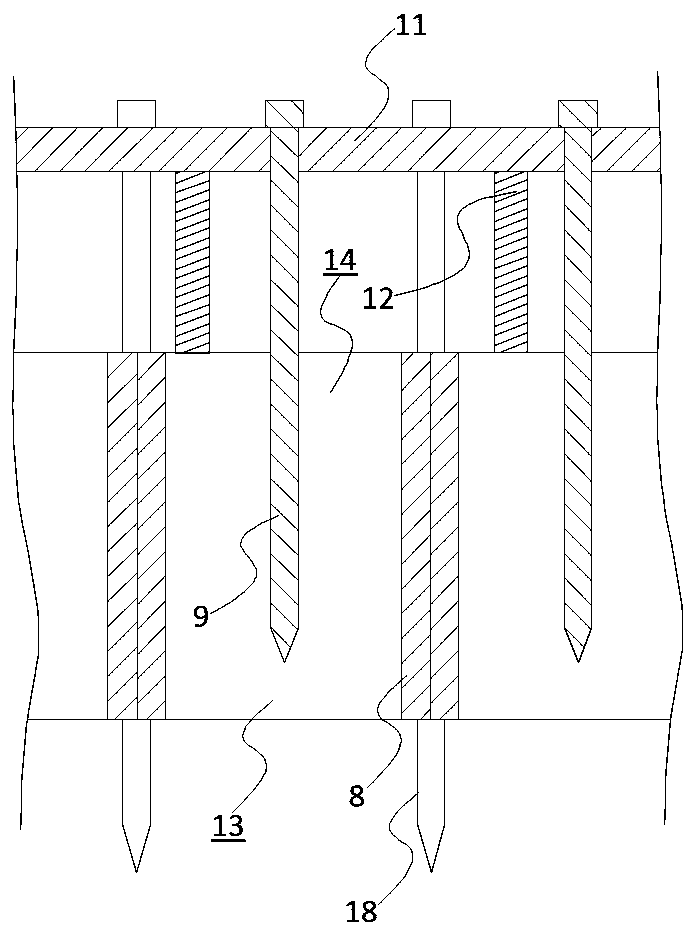

[0022] Example: such as figure 1 As shown, the high-efficiency flue gas purification device of this embodiment includes a housing 1 , a flue gas inlet 2 and a flue gas outlet 3 are opened at both ends of the housing 1 , and a flue gas passage 4 is inside the housing 1 . The number of high-voltage discharge modules is two, the number of plate-type dust collection modules 5 is three, and the two high-voltage discharge modules are respectively a high-voltage discharge module 6a and a high-voltage discharge module 6b. During the process of purifying the flue gas, the flue gas enters the interior of the housing 1 from the flue gas inlet 2, along the flue gas passage 4, the high-voltage discharge module 6a, the first plate-type dust collection module 5, the high-voltage discharge module 6b, the second plate-type dust collection module The dust collection module 5 , the third plate dust collection module 5 and the porous ceramic plate 7 are finally discharged from the flue gas outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com