Pipe baking device used for pipeline construction

A technology of pipeline construction and pipe bending device, applied in the field of pipeline processing, can solve the problems of poor quality, high price of hydraulic simmering and bending machine, difficult handling on construction site, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

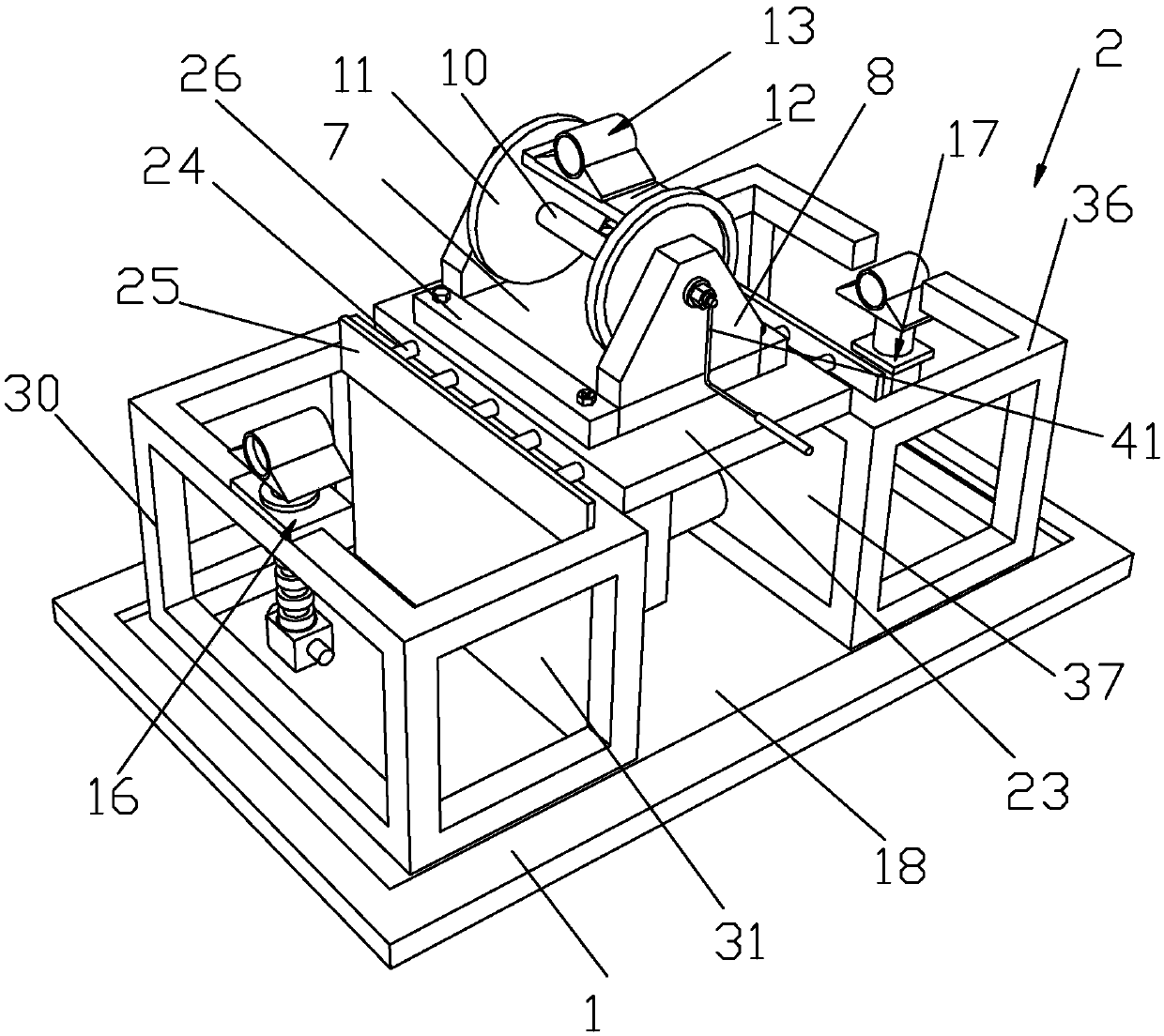

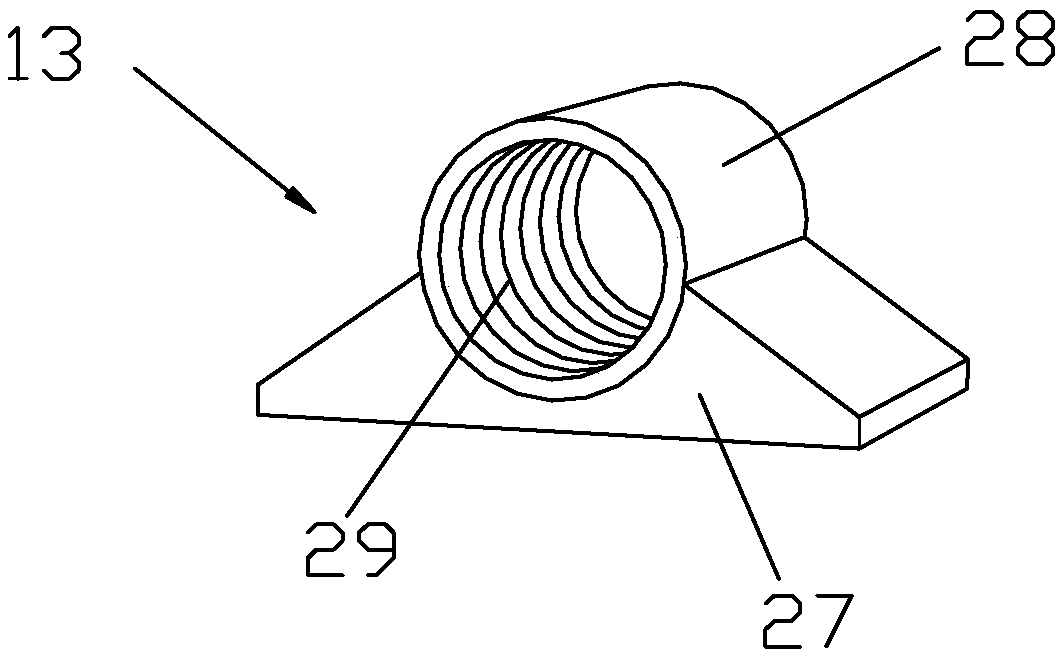

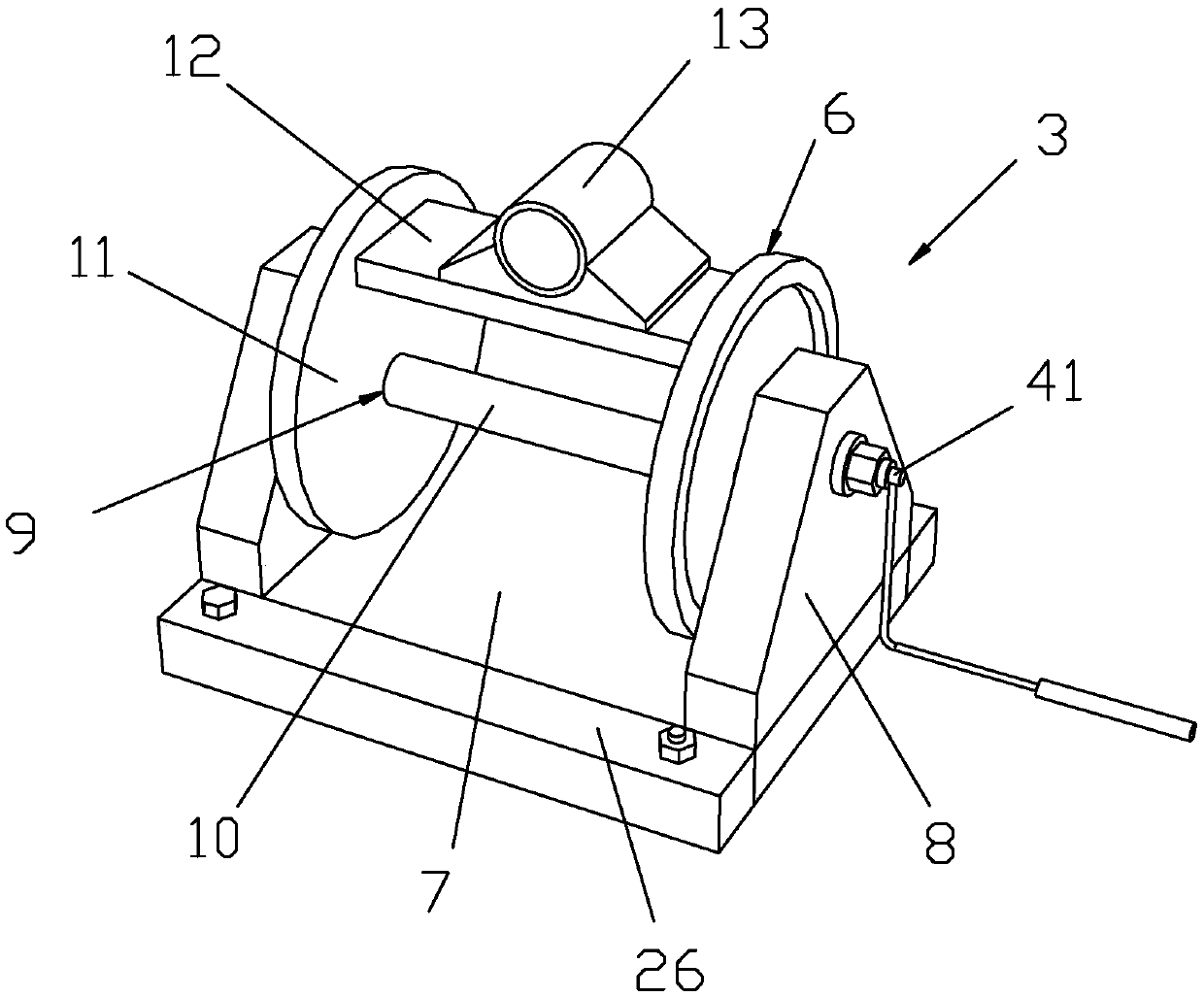

[0027] Such as Figure 1 to Figure 8 As shown, it is a pipe simmering device for pipeline construction of the present invention, including a workbench 1 and a simmering device 2, the simmering device 2 includes a pipe bending device 3 and a limiting device 4, and the pipe bending device 3 includes a mounting seat 5 and a bending device The tube bender 6, the tube bender 6 includes a bottom support plate 7, a lateral support plate 8 and a rotation mechanism 9, the rotation mechanism 9 includes a rotation shaft 10, a rotation disc 11 and a positioning plate 12, and the side support plate 8 is fixedly installed on the bottom support On both sides of the plate 7, a rotating shaft 10 is connected between the lateral support plates 8, and a rotating disc 11 is fixedly installed on both sides of the rotating shaft 10, and the rotating disc 11 is sleeved on the rotating shaft 10, and the rotating handle 41 passes through the lateral The support plate 8, the rotary handle 41 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com