Shell Extrusion Pressing Die

A casing and mold technology, applied in the field of casing extrusion hole pressing mold, can solve the problems of inconvenient removal of the casing, low work efficiency, inability to perform hole extrusion and pressing operation at the same time, etc., so as to prolong the service life and improve the The effect of working efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is further described in detail through specific implementation methods:

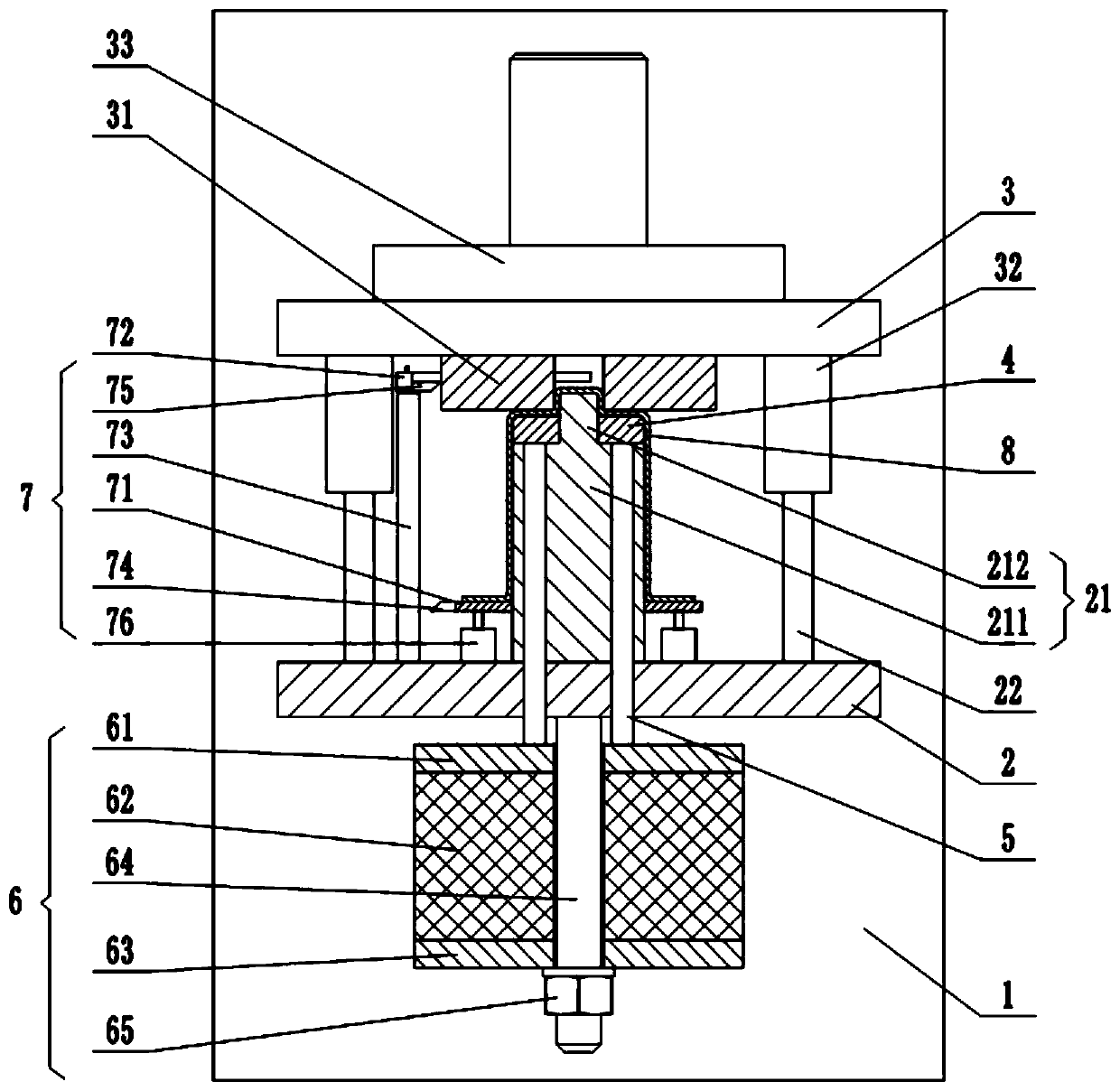

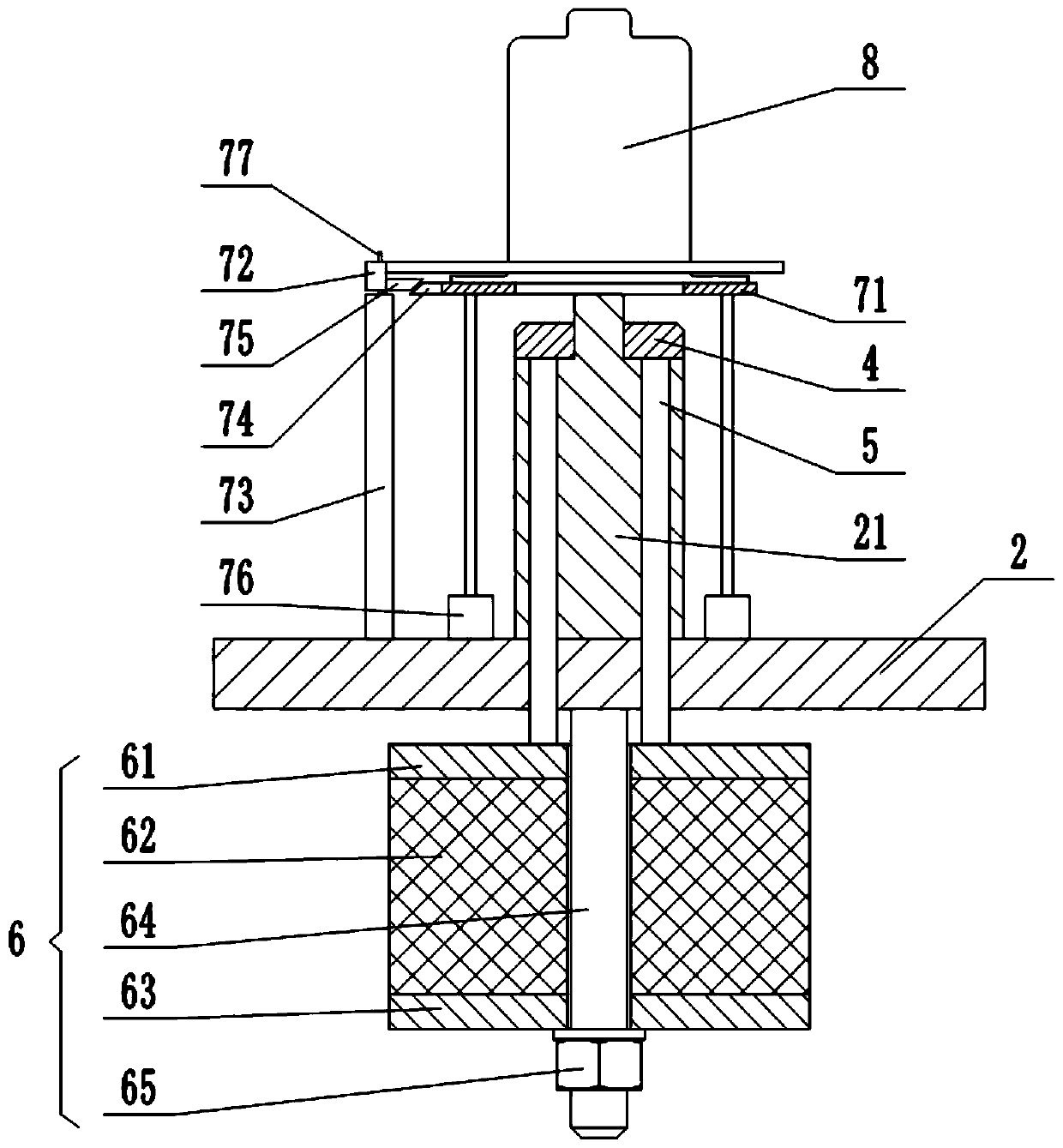

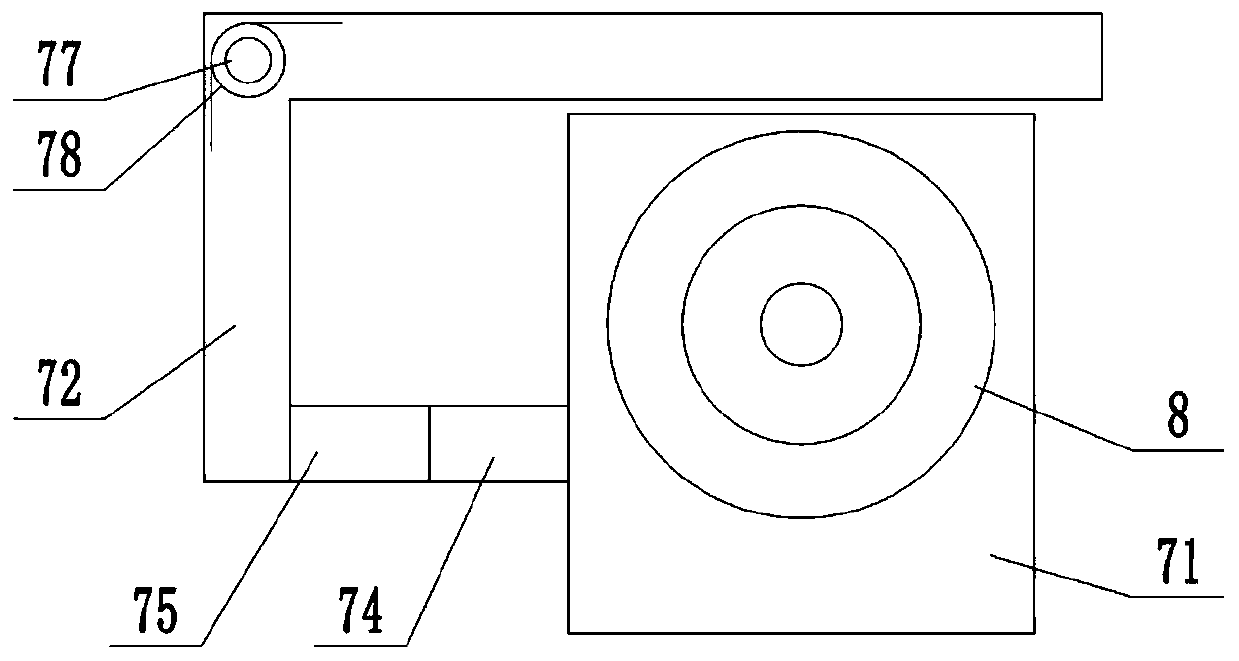

[0024] The reference signs in the accompanying drawings of the description include: frame 1, lower die base 2, punch 21, large diameter end 211, small diameter end 212, guide post 22, upper die base 3, die 31, guide sleeve 32, mold Handle 33, marking die 4, material return rod 5, elastic demoulding mechanism 6, first backing plate 61, elastic member 62, second backing plate 63, support rod 64, fixing bolt 65, pushing material unloading mechanism 7, unloading Material plate 71, push rod 72, pillar 73, first wedge bar 74, second wedge bar 75, cylinder 76, positioning pin 77, torsion spring 78, casing 8.

[0025] The embodiment is basically as figure 1 and figure 2 Shown: a casing extrusion die, including a frame 1, a fixed lower mold base 2 and a lower mold base 3 that can be close to or far away from the lower mold base 2 are arranged on the frame 1, specifically, the upper mold ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com