Sleeve forming method

A sleeve and flange technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of cumbersome process flow, low production efficiency, low material utilization rate, etc., to reduce impact, improve material utilization rate, The effect of reducing the forming process and the undercarriage process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Wherein, the same parts use the same reference numerals.

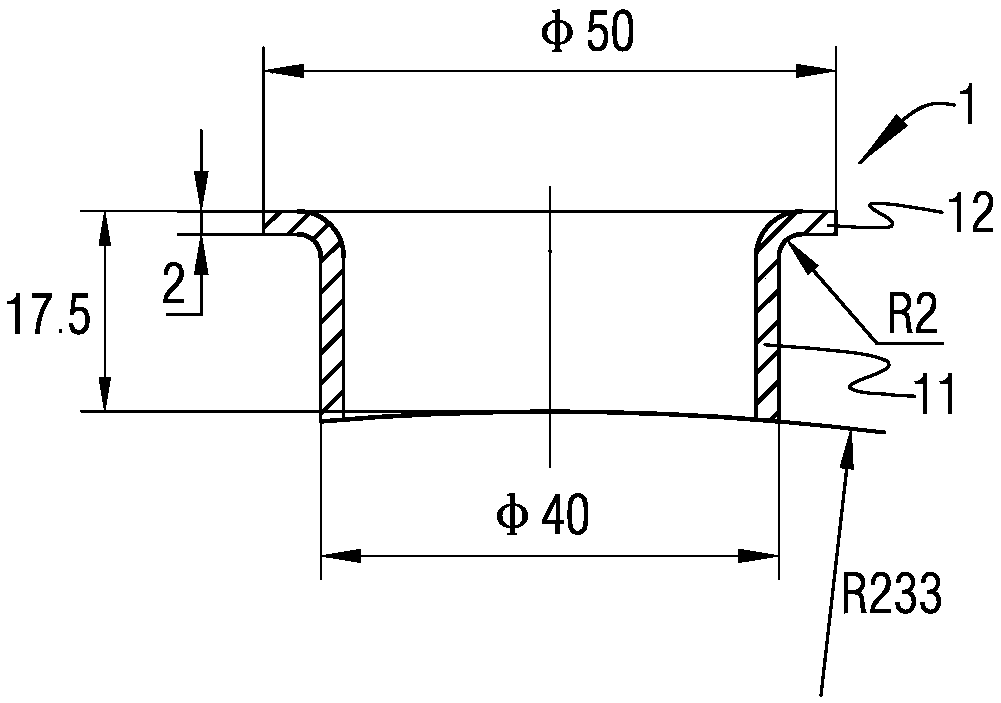

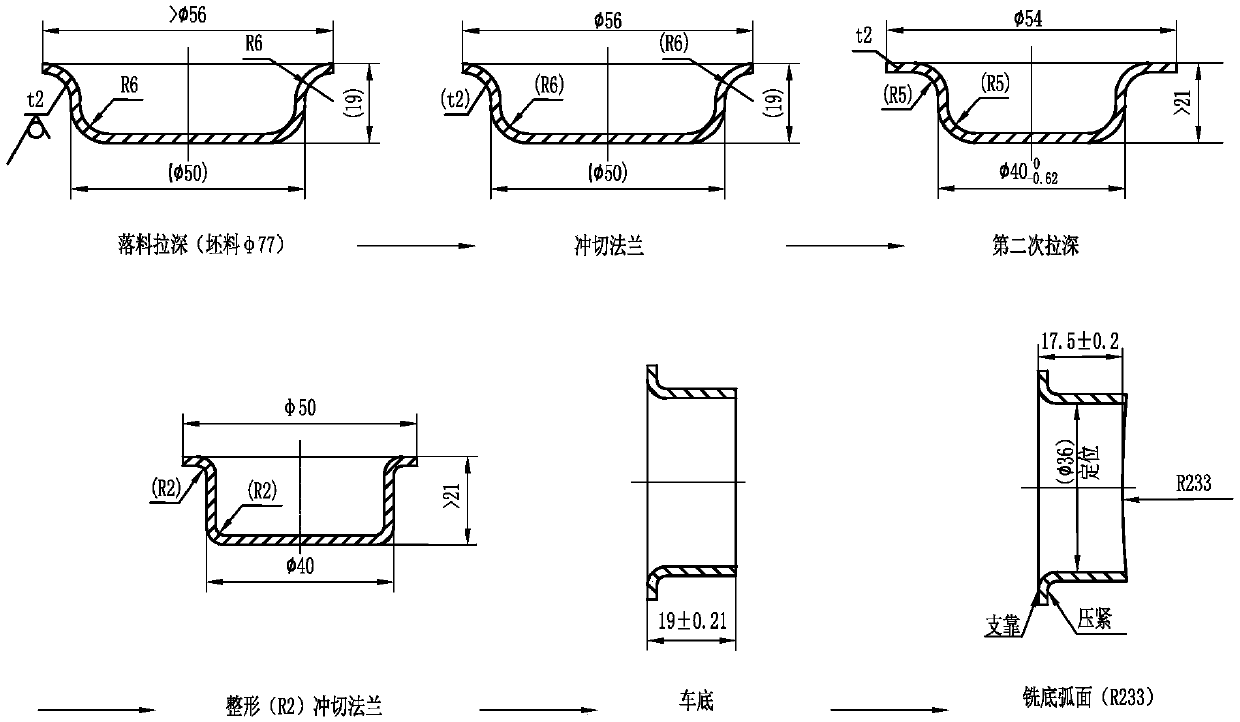

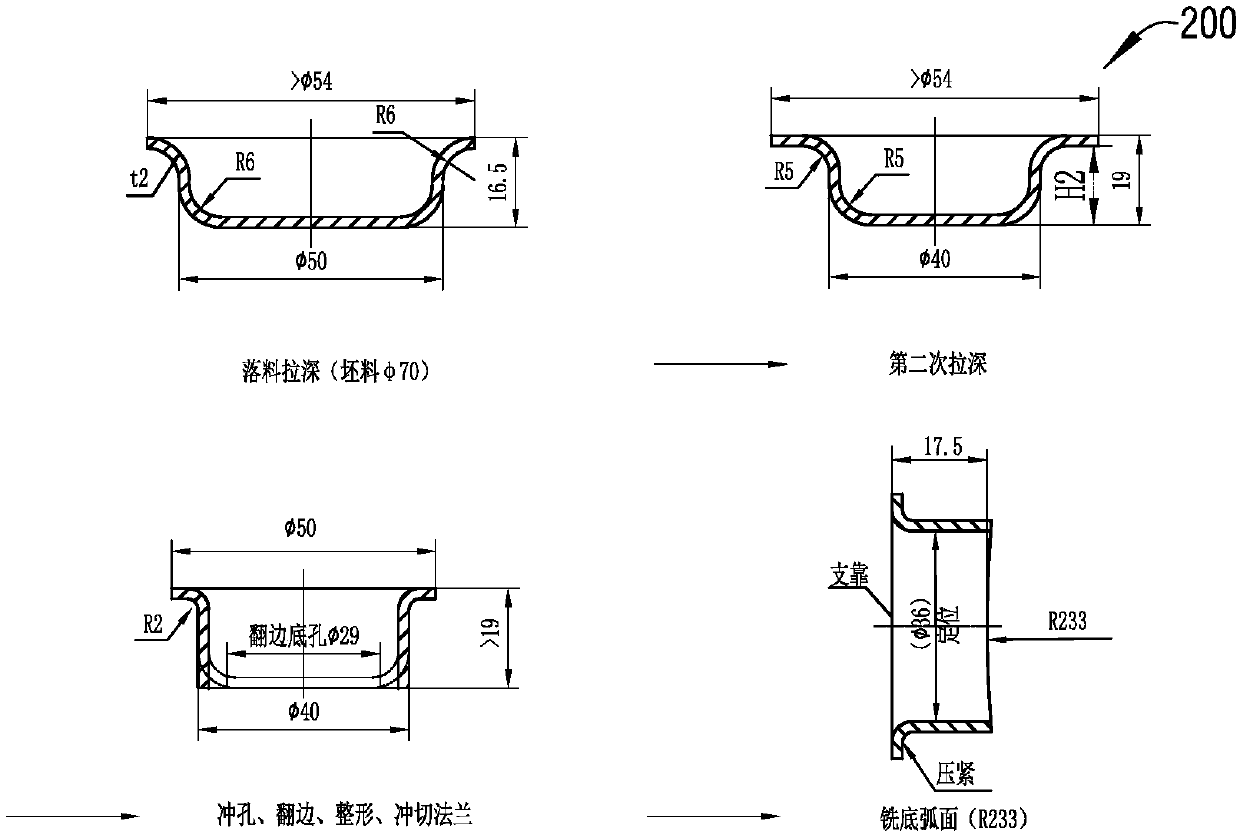

[0031] figure 1 is a schematic cross-sectional structural diagram of an engine sleeve; image 3 It is a schematic process flow diagram of a sleeve forming method according to a specific embodiment of the present invention; Figure 4 for image 3 A schematic cross-sectional structure diagram of the mold in step C of the method. exist Figure 4 In , the structure of the cutting edge is shown in the partial enlarged schematic diagram of A, see figure 1 , image 3 and Figure 4 As shown, the present invention provides a sleeve forming method for processing such as figure 1 As shown in the sleeve, the wall thickness of the sleeve 1 is 2mm, including a straight portion 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com