Additive manufacturing and subtractive manufacturing composite machining equipment

A technology of compound processing, adding and subtracting materials, applied in the field of metal 3D printing, can solve the problems of thermal deformation of the base, disordered air circulation, large focal length, etc., achieve strong thermal deformation resistance, prevent metal powder, and solve the effect of circulating filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

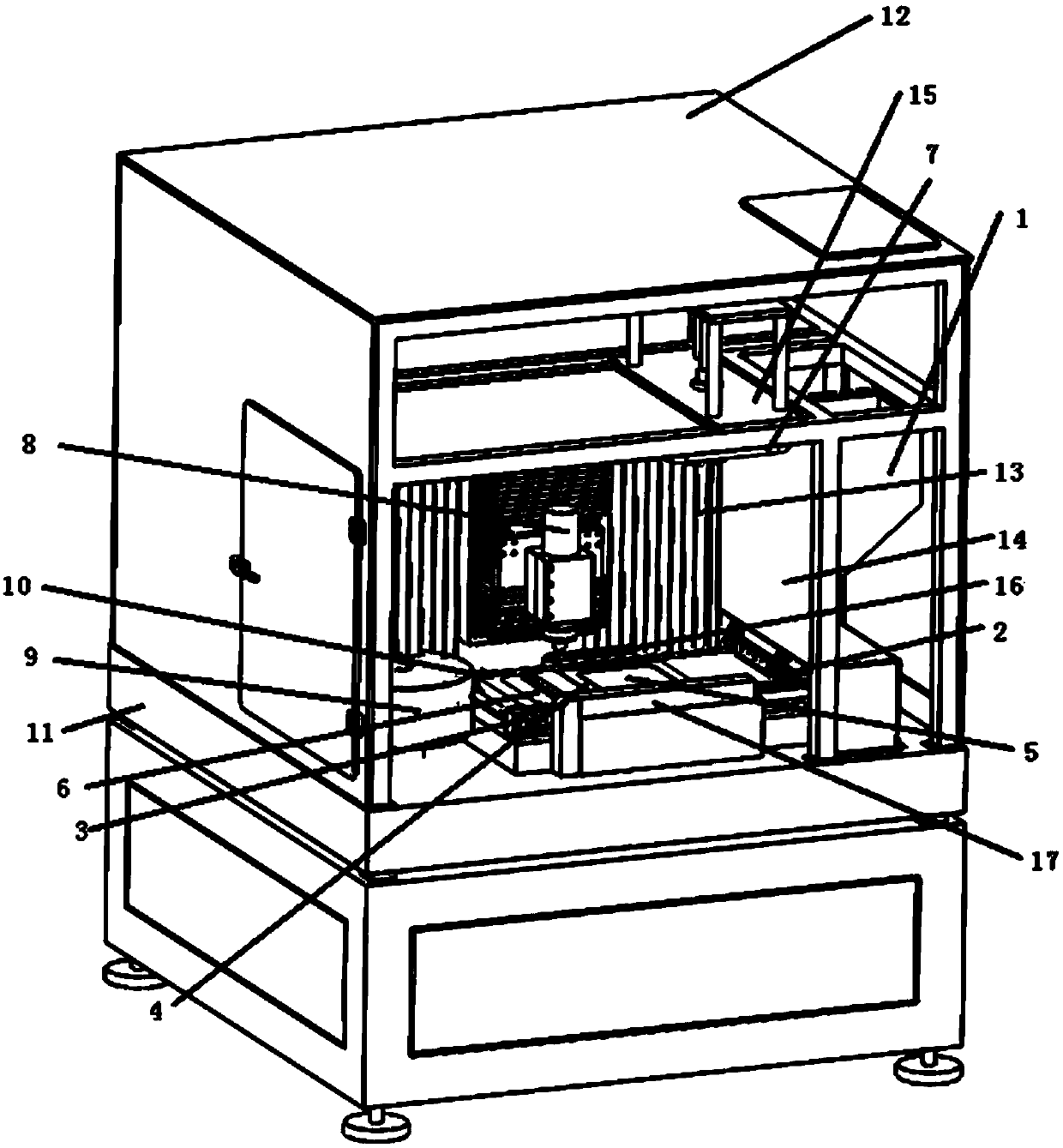

[0021] refer to figure 1 and figure 2 , in one embodiment, an additive and subtractive composite processing equipment, including a sealed chamber 12 and an additive manufacturing device and a subtractive manufacturing device that are located in the sealed chamber 12 together, and the additive manufacturing device includes The upper powder feeding mechanism 1, the powder spreading mechanism 2, the powder spreading mechanism driving module 3, the laser 7, the laser lifting mechanism 15 and the molding chamber 4, the upper powder feeding mechanism 1 is arranged above the powder spreading mechanism for Quantitative powder feeding to the powder spreading mechanism 2, the powder spreading mechanism driving module 3 is coupled to the powder spreading mechan...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap