Three-degree-of-freedom automatic fodder palletizing mechanism device with closed chain structure

A technology of structural form and mechanical device, which is applied in the field of automatic material palletizing mechanical device, can solve the problems of large cumulative error, small carrying capacity, and low precision of series manipulators, and achieve flexible and diversified motion trajectories, large carrying capacity, and improved dynamics. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

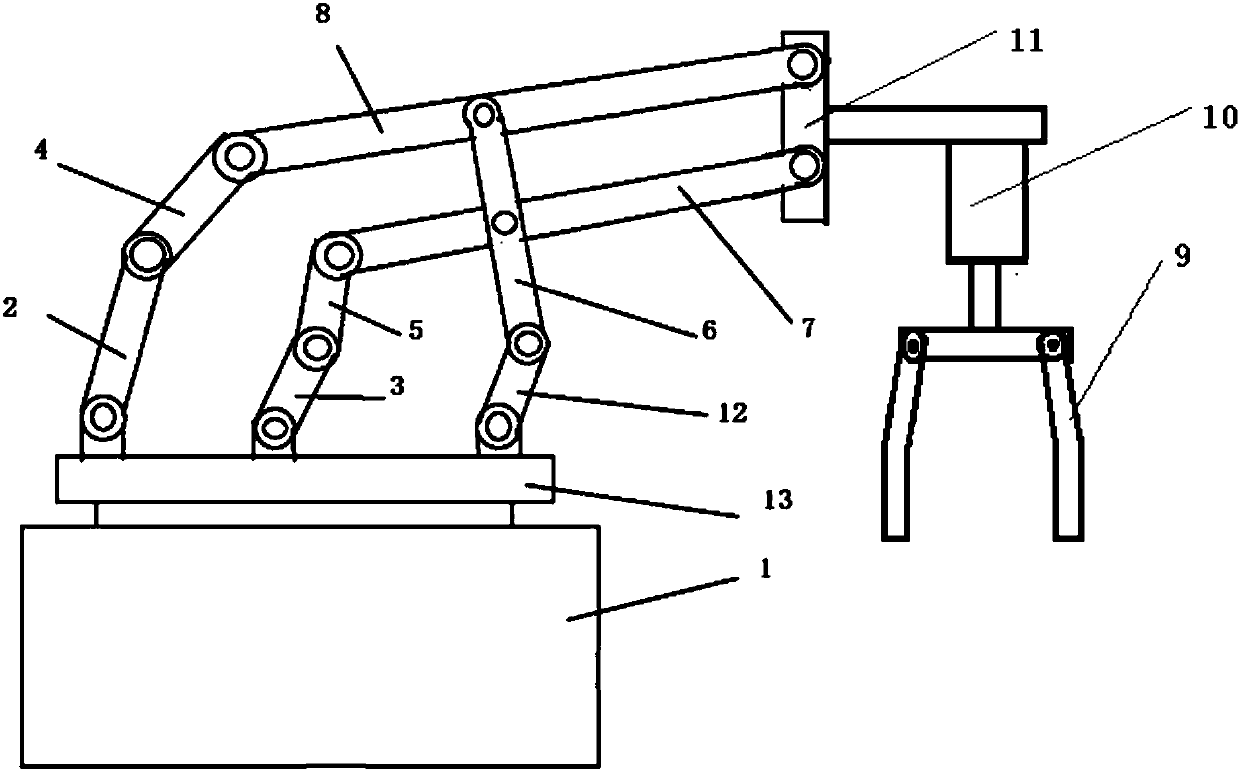

[0006] A three-degree-of-freedom feed automatic palletizing mechanism adopts a closed-chain structure, including: a base 1, a rotatable platform 13, a telescopic mechanism, a lifting mechanism, a pitching mechanism, and a wrist link 11, a wrist 10, and a claw 9. Telescoping mechanism comprises: the first active rod 2, the second connecting rod 4 and the first big arm 8; One end of the first active rod 2 is hinged on the rotatable platform 13, and one end of the second connecting rod 4 is connected with the first active rod 2 The other end of the first boom 8 is hinged with the other end of the second connecting rod 4 . The lifting mechanism includes a second active rod 3, a third connecting rod 5 and a second big arm 13; one end of the second active rod 3 is hinged on the rotatable platform 13, and one end of the third connecting rod 5 is connected to The other end is hinged, and one end of the second big arm 13 is hinged with the other end of the third connecting rod 5; the p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap