Fine force touch based explosive-disassembling robot capable of being remotely operated

A remote operation and refined technology, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the hidden dangers of operator's personal safety, cannot guarantee the correct operation of the bomb disposal process, cannot reflect the size of the contact force, etc. Safety hazard, reducing impact, reducing the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

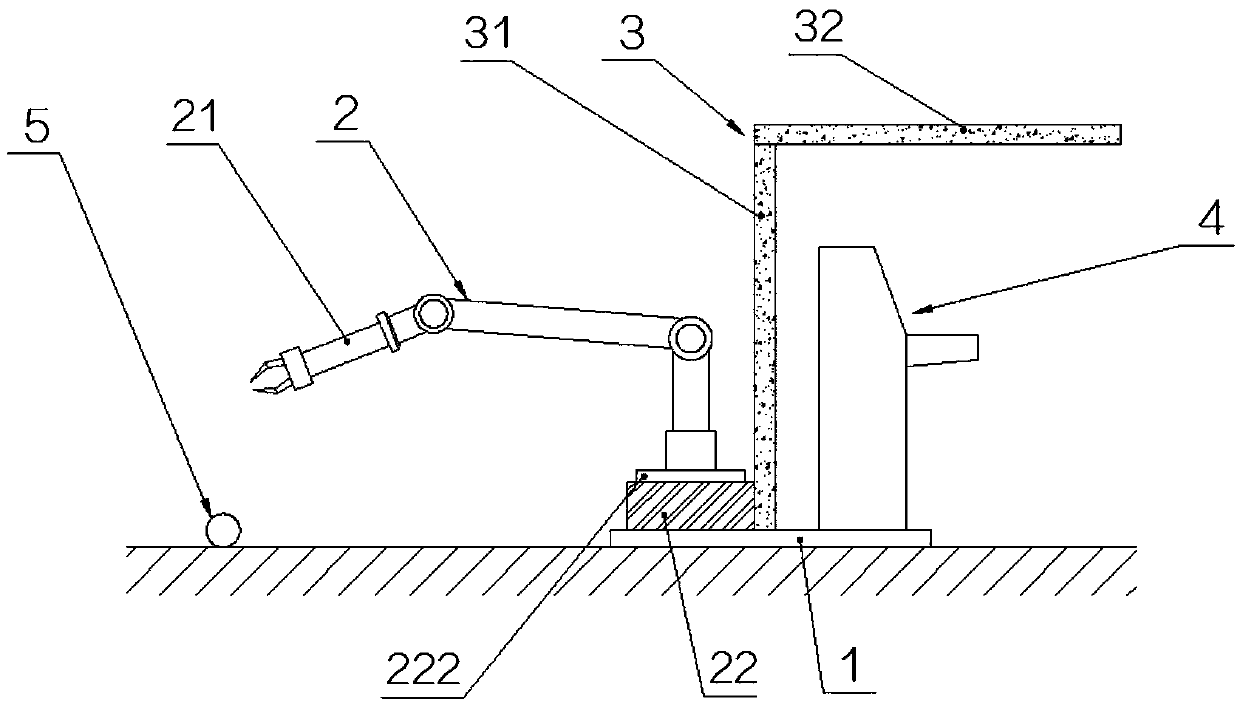

[0024] Such as Figure 1-3 As shown, a remote-operated bomb disposal robot based on refined haptics includes a base plate 1 on which a manipulator bomb disposal mechanism 2, an isolation protection mechanism 3, and an on-site operating platform 4 are fixed. The manipulator The bomb disposal mechanism 2 and the on-site operation platform 4 are respectively located on both sides of the isolation protection mechanism 3;

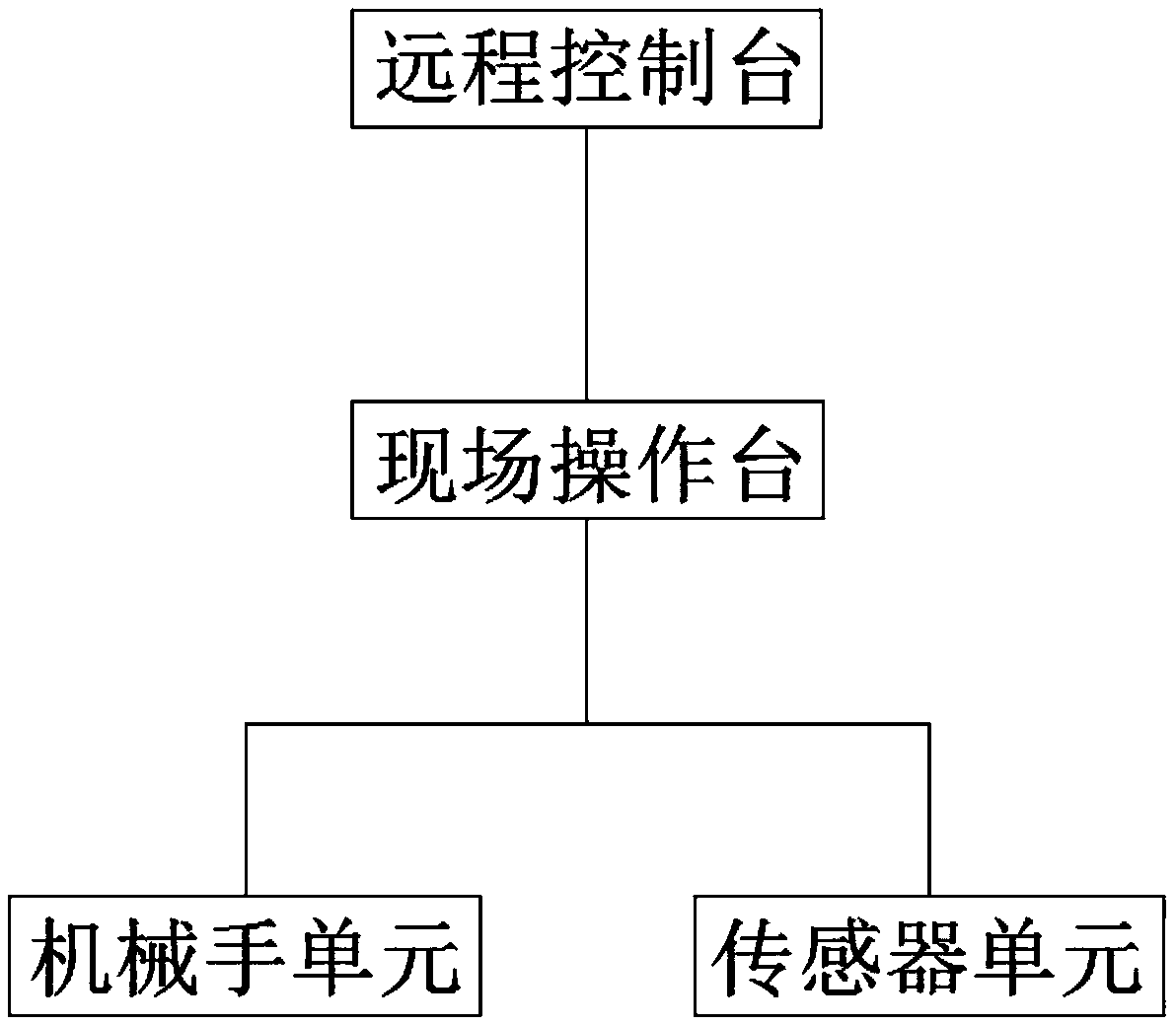

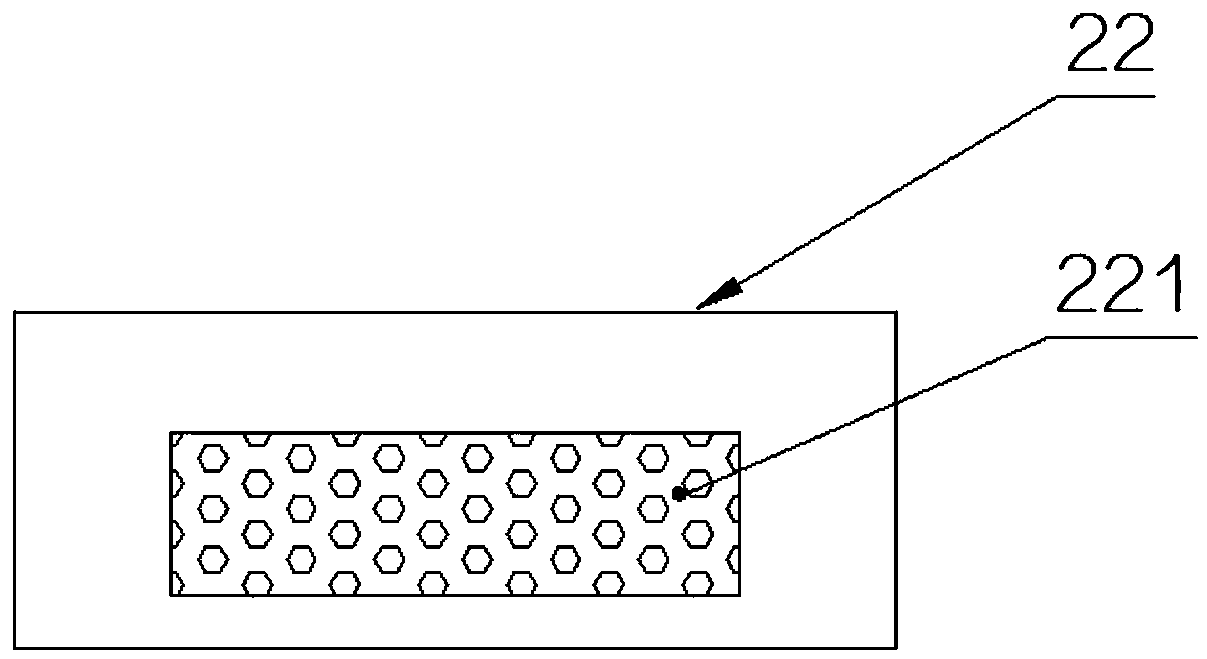

[0025] The manipulator bomb disposal mechanism 2 includes a manipulator unit 21 and a sensor unit, the manipulator unit 21 and the sensor unit are electrically connected to the field operation table 4, and the sensor unit is fixedly installed on the manipulator unit 21;

[0026] The on-site operation console 4 is provided with a touch display screen, and the on-site operation console 4 is connected to a remote console through wireless com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com