Perforating device for furniture plate

A punching device and plate technology, which is applied to fixed drilling machines and other directions, can solve the problems of high working intensity, poor punching quality, and poor wedging, so as to ensure the processing quality and effect, improve processing efficiency, and improve product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

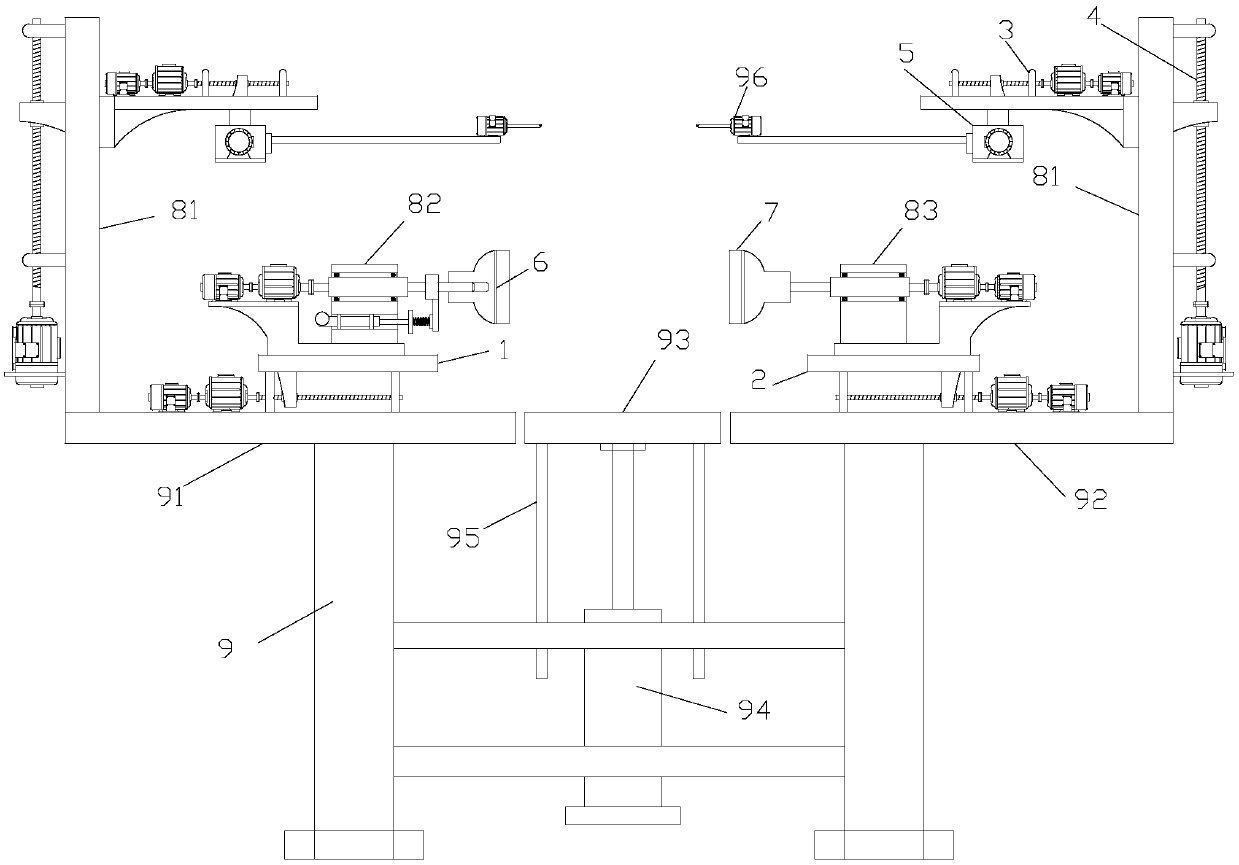

[0038] like figure 1As shown, the punching device for furniture panels described in this embodiment includes a left platen 91 and a right platen 92 on the frame 9, each of which is provided with a punching mechanism 81, and two punching Hole mechanism 81 is arranged oppositely, is provided with lifting plate 93 in the gap between left platen 91 and right platen 92, below lifting plate 93 is positioned at the lifting cylinder 94 that is used to drive lifting plate 93 lifting on frame 9, lifts Plate 93 below is also provided with the guide bar 95 that can pass through frame 9 lifts; The splint mechanism 83 is relatively arranged, and is characterized in that:

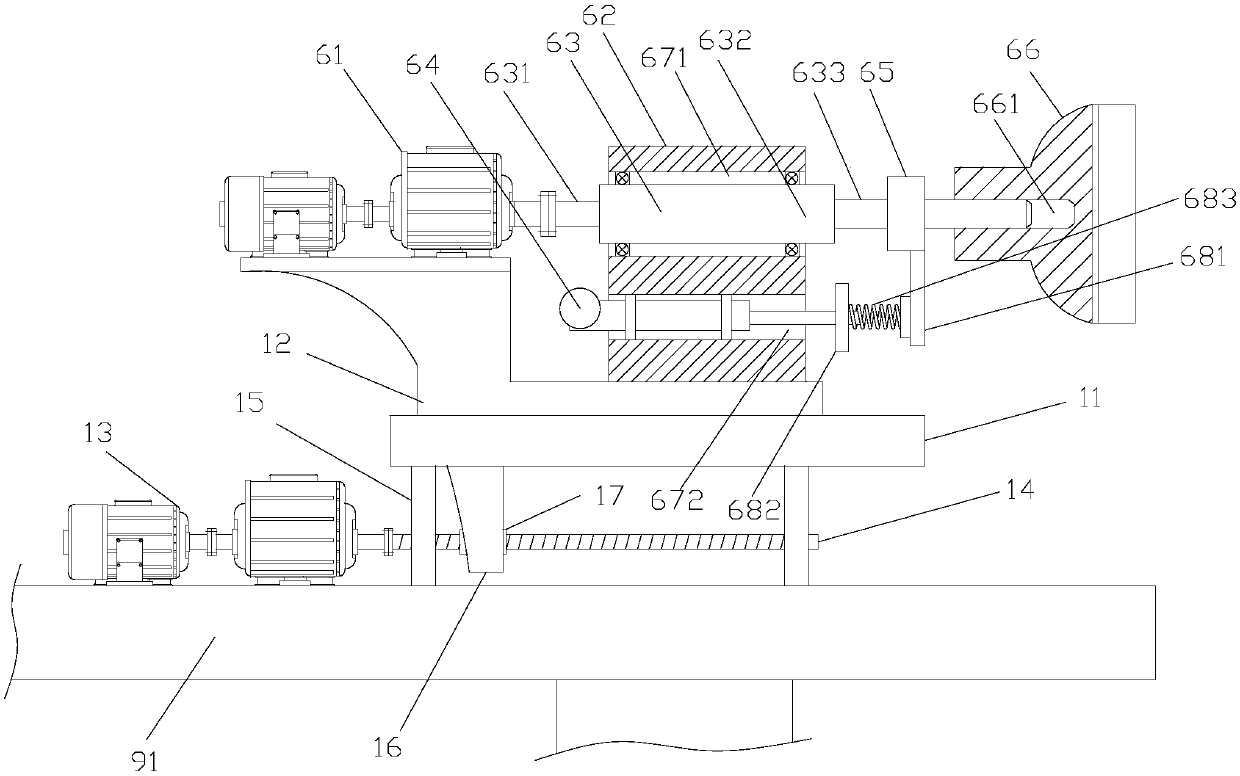

[0039] The left splint mechanism 82 includes a translation mechanism 1 and a movable splint mechanism 6;

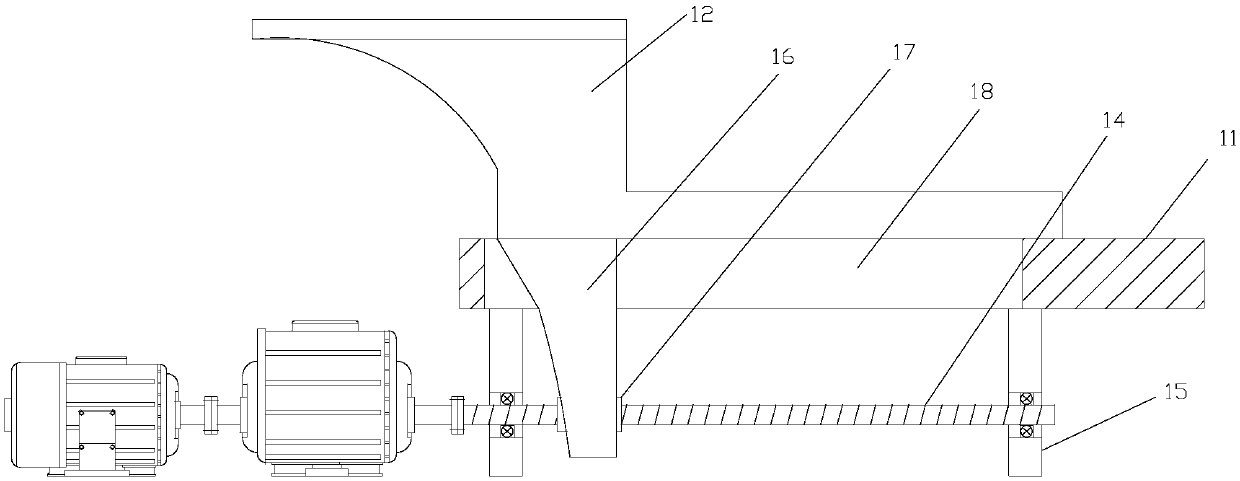

[0040] like image 3 , the translation mechanism-1 includes a base plate-11, a moving seat-12, a drive unit-13, a screw rod-14 and two bearing seats-15 at the front and rear; two bearing seats-15 are fixedly arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com