Impregnating adhesive, impregnated bond paper and preparation method of veneer of impregnated bond paper

A technology of impregnating film paper and impregnating glue, which is applied in the field of wood processing, can solve the problems of easy cracking, high production cost, and complicated preparation process, and achieve the effect of not easy to stick, low cost, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

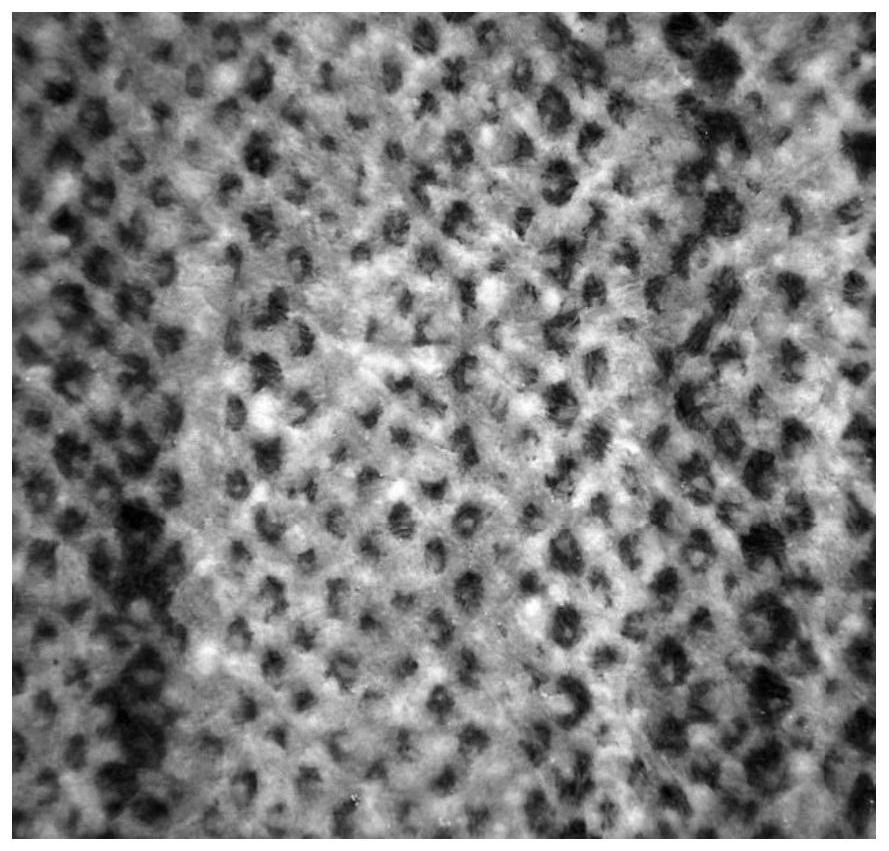

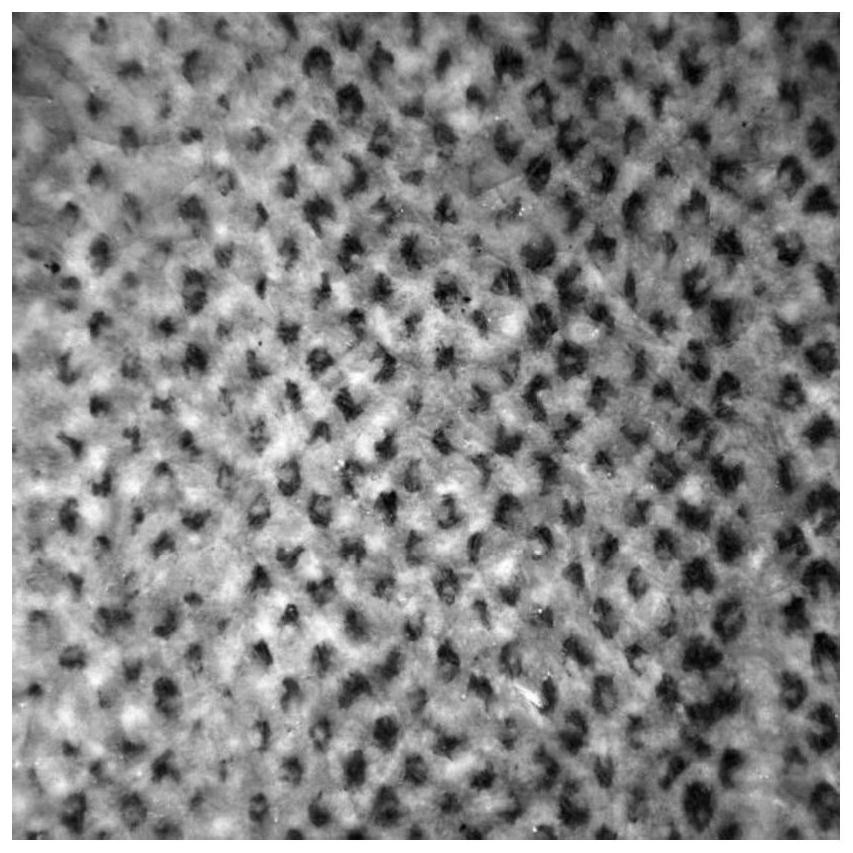

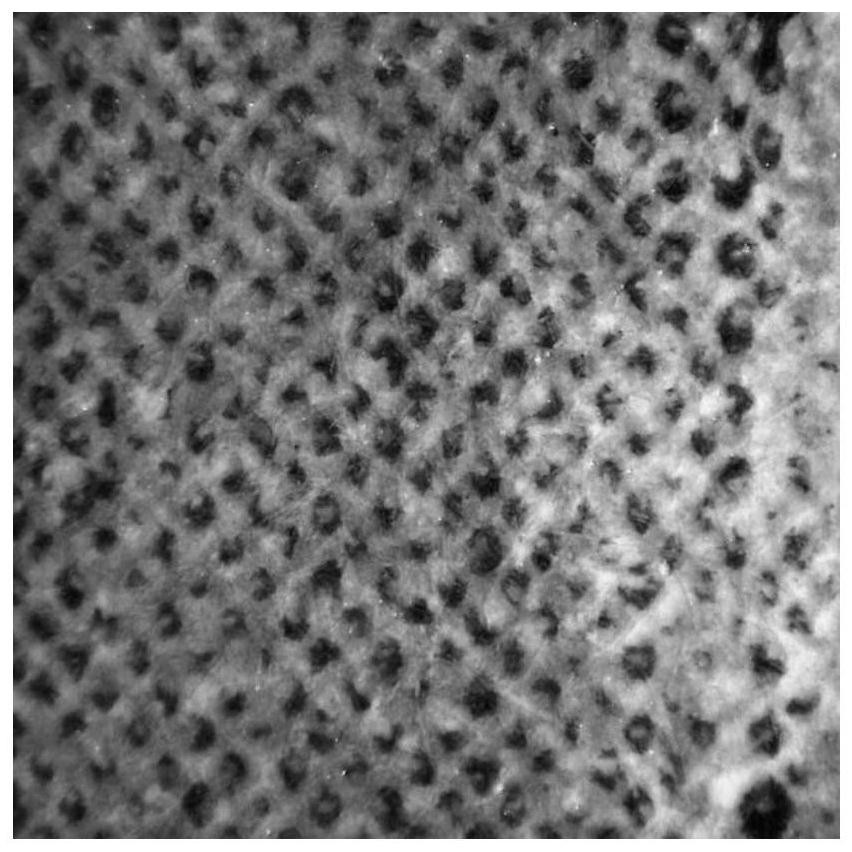

Image

Examples

preparation example Construction

[0038] The second aspect of the present invention provides a preparation method of impregnated adhesive film paper, said method comprising: first immersing the raw material paper in the urea-formaldehyde resin impregnating solution to obtain paper I, and then coating the impregnating glue described in the first aspect of the present invention Cloth on paper I, obtain impregnated adhesive film paper.

[0039] Among them, the impregnated film paper prepared by using urea-formaldehyde resin and the impregnated glue described in the first aspect of the present invention has the advantages of good flexibility, easy storage, and less likely to cause adhesion.

[0040] In a preferred embodiment, the present invention does not specifically limit the raw material paper, and any common raw material paper in the field can be used in the present invention.

[0041] In a preferred embodiment, the urea-formaldehyde resin impregnation solution includes urea-formaldehyde resin and water, wher...

Embodiment 1

[0068] 1) At room temperature, soak the raw paper in an aqueous solution of urea-formaldehyde resin (the weight-average molecular weight of the urea-formaldehyde resin is 700, and the mass content is 55%) for 40 seconds, then take it out, and dry it at 110° C. for 2 minutes to obtain paper I; The impregnation amount of urea-formaldehyde resin is 100g / m 2 ;

[0069] 2) Add 1g blocked isocyanate A, 0.005 organotin catalyst A, 2g caprolactam, 1g polyethylene glycol (weight average molecular weight 400) and 0.1g release agent A to 100g melamine-formaldehyde resin aqueous solution, stir evenly at room temperature, Obtain impregnation glue, adopt roll coating mode to impregnate glue coating on paper I, dry 3min at 110 ℃, obtain impregnation film paper; Wherein, the coating amount on impregnation film paper is 50g / m 2 ;

[0070] 3) Put the above-mentioned impregnated film paper on the blockboard, and press it under the conditions of 120° C. and 1 MPa for 7 minutes to obtain the imp...

Embodiment 2

[0072] 1) At room temperature, soak the raw paper in an aqueous solution of urea-formaldehyde resin (the weight-average molecular weight of the urea-formaldehyde resin is 900, and the mass content is 60%) for 45 seconds, then take it out, and dry it at 110° C. for 3 minutes to obtain paper I; The impregnation amount of urea-formaldehyde resin is 110g / m 2 ;

[0073] 2) Add 3g blocked isocyanate A, 0.015g organotin catalyst B, 1g caprolactam, 2g polyethylene glycol (weight average molecular weight 400) and 0.2g release agent A to 100g melamine formaldehyde resin aqueous solution, stir evenly at room temperature , to obtain the impregnation glue, adopt the roll coating method to apply the impregnation glue on the paper I, dry 3min at 110°C, and obtain the impregnation film paper; wherein, the coating amount on the impregnation film paper is 60g / m 2 ;

[0074] 3) Put the above-mentioned impregnated film paper on the blockboard, and press it under the conditions of 110° C. and 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com