Antistatic and environmentally friendly fabric and preparation method thereof

An antistatic and antistatic layer technology, applied in the field of fabrics, can solve the problems that fabrics cannot be used in special occasions, have a single function, and do not have antistatic properties, so as to improve health, improve waterproof performance, and improve antistatic performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

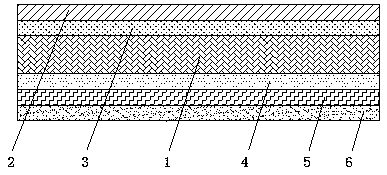

[0027] see figure 1 , an antistatic environmentally friendly fabric, comprising a base fabric layer 1, a fireproof layer 2, an antistatic layer 3, a waterproof layer 4, a health care layer 5 and a breathable layer 6, the base fabric layer 1 is woven by interlacing warp threads and weft threads, and the warp threads Linen fiber is used, soybean fiber is used for the weft, and the top of the base fabric layer 1 is connected with an antistatic layer 3 through environmentally friendly acrylic glue, which can effectively improve the antistatic performance of the fabric. The antistatic layer 3 is woven by interlacing warp and weft. And the warp yarn is mixed with cotton yarn and 5D chenille yarn, and the mass ratio of cotton yarn and 5D chenille yarn is 6:4, the weft yarn is mixed with conductive fiber and nylon, and the mass ratio of conductive fiber and nylon is 3.5:6.5, and The top of the antistatic layer 3 is connected with the fireproof layer 2 through an environment-friendly a...

Embodiment 2

[0039] see figure 1, an antistatic environmentally friendly fabric, comprising a base fabric layer 1, a fireproof layer 2, an antistatic layer 3, a waterproof layer 4, a health care layer 5 and a breathable layer 6, the base fabric layer 1 is woven by interlacing warp threads and weft threads, and the warp threads Linen fiber is used, soybean fiber is used for the weft, and the top of the base fabric layer 1 is connected with an antistatic layer 3 through environmentally friendly acrylic glue, which can effectively improve the antistatic performance of the fabric. The antistatic layer 3 is woven by interlacing warp and weft. And the warp yarn is mixed with cotton yarn and 5D chenille yarn, and the mass ratio of cotton yarn and 5D chenille yarn is 6:4, the weft yarn is mixed with conductive fiber and nylon, and the mass ratio of conductive fiber and nylon is 3.5:6.5, and The top of the antistatic layer 3 is connected with the fireproof layer 2 through an environment-friendly ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com