A Follower Mechanism for the Folding Cover of the Wing of a Carrier Aircraft

A technology of wing folding and follow-up mechanism, which is applied in the direction of wing adjustment, etc., can solve the problem that the flap flipping method is difficult to meet the requirements of carrier-based aircraft wing folding flaps, etc., and achieve the effect of simple mechanism and good structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

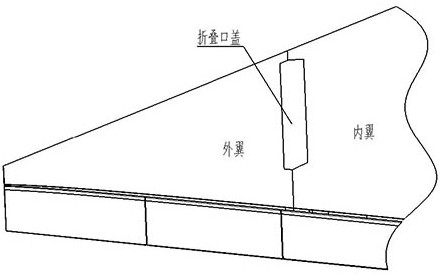

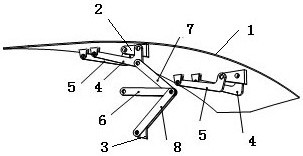

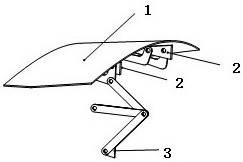

[0025] combined with Figure 1-3 As shown, a follower mechanism of a carrier-based aircraft wing folding cover, including a cover 1, an inner wing ear piece 2 fixedly installed on the inner wing, and an inner wing ear piece 3 fixedly installed on the inner wing And the link mechanism, the flap 1, the A inner wing lugs 2 and the B inner wing lugs 3 are connected to each other through the link mechanism, and the link mechanism includes a flip cover link mechanism and a follower link 6 mechanism, so The mouth cover 1 is connected with the A inner wing lug 2 through the flip cover linkage mechanism, and the B inner wing lug 3 is connected with the flip cover linkage mechanism through the follower link 6 mechanism.

[0026] The present invention is a follow-up mechanism for a wing folding flap 1 of a carrier-based aircraft. The flap 1 is flipped through a link mechanism, and the shape of the wing is a curved surface, and the folding rotation axis of the wing is arranged in the aero...

Embodiment 2

[0028] On the basis of the above-mentioned embodiments, this embodiment combines the attached Figure 1-3 As shown, further defined, the flip cover linkage mechanism includes a crank 4 and a rocker 5, the two ends of the crank 4 are respectively hinged to the port cover 1 and the A inner wing ear piece 2, and the two ends of the rocker 5 are respectively Hinged port cover 1 and A inner wing lug 2, the crank 4 and the rocker 5 are located on both sides of the A inner wing ear 2 and the hinge points do not coincide, the crank 4 and the rocker 5 on the port cover 1 The hinge points do not coincide. Wherein A inner wing lug 2 is fixed on the inner wing of the aircraft to provide support for the movement of the linkage mechanism, while the crank 4 and the rocker 5 are all hinged on the flap 1, and the hinge points do not coincide, while the other end of the crank 4 and the other end of the rocking bar 5 are hinged on the inner wing lug 2 of A but the hinge points do not coincide, ...

Embodiment 3

[0031] On the basis of the above-mentioned embodiments, this embodiment combines the attached Figure 1-3 As shown, further defined, the follower link 6 mechanism includes a follower link 6, a drive link 7 and a drive crank 84, and the two ends of the drive crank 84 are respectively hinged to the B inner wing ear piece 3 and the drive link 7. The other end of the transmission connecting rod 7 is hinged to the crank 4, and the end of the transmission crank 84 away from the B inner wing lug 3 is also hinged to the follower connecting rod 6. Wherein B inner wing lug 3 provides stable supporting force for follower link 6 mechanism, and follower link 6 is hinged at the hinge point of drive link 7 and drive crank 84, makes the small angle of follower link 6 The rotation can be converted into a large-angle rotation of the transmission link 7, and the other end of the transmission link 7 is hinged on the crank 4, so the large-angle rotation of the transmission link 7 drives the large-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com