Reusable carrier rocket core first-stage rocket body recycling power system

A technology of power system and launch vehicle, which is applied to the power supply system of space navigation vehicle, the guidance device of space navigation vehicle, etc., can solve the problems such as the inability to exert the thrust advantage of the launch vehicle engine and the loss of engine thrust, so as to reduce the difficulty and cost of research and development. Significant progress, highlighting the effect of substantive features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to clearly illustrate the technical characteristics of this solution, the following will describe this solution through specific implementation modes and in conjunction with the accompanying drawings.

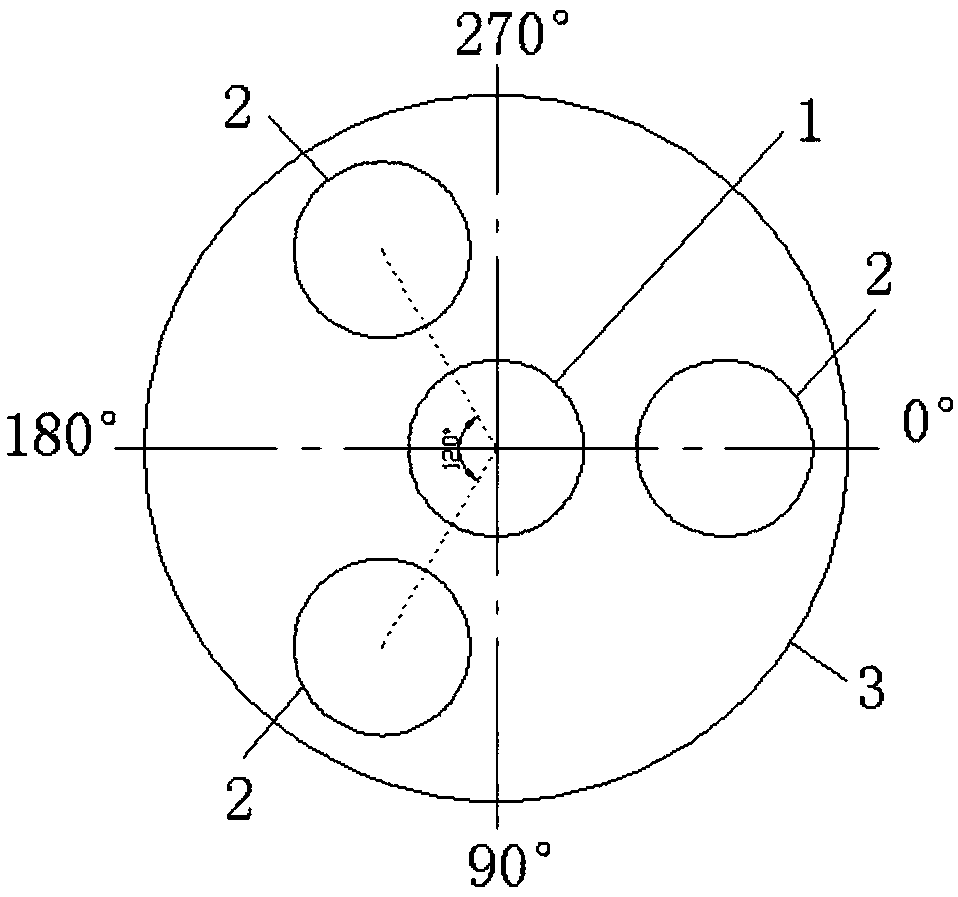

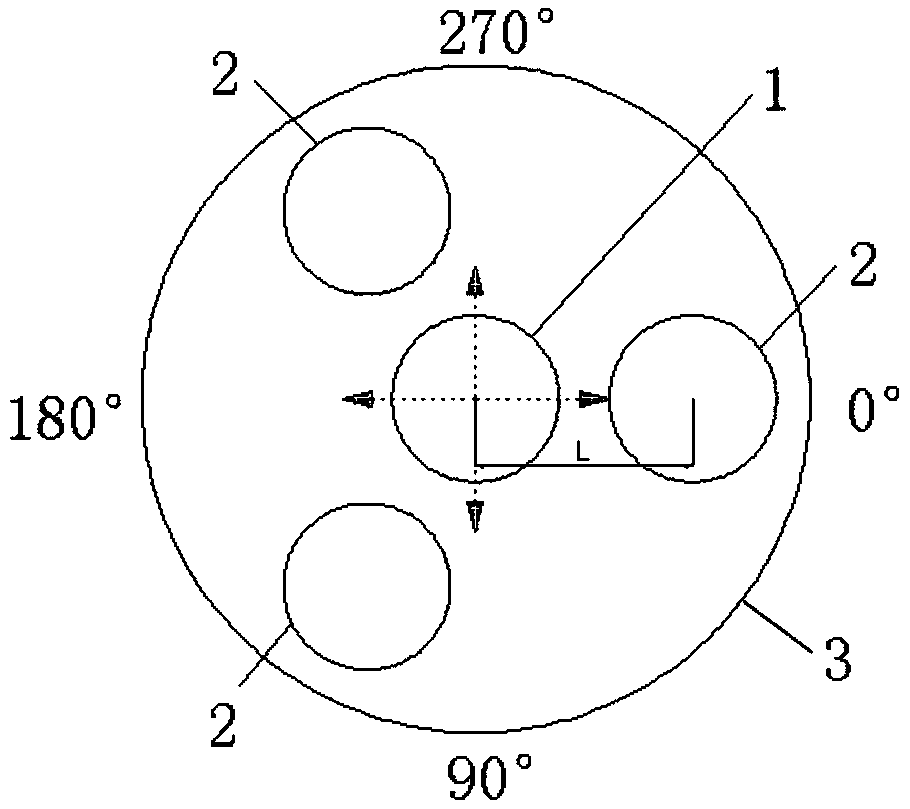

[0022] A reusable launch vehicle core first-stage rocket body recovery power system, as shown in the figure, it includes an intermediate engine 1 and three circumferential engines 2 installed on the core first-stage rocket body 3, the intermediate engine 1 and three circumferential engines 2 are liquid oxygen methane engines. The middle engine 1 is a swing engine, and the axis of the middle engine 1 coincides with the axis of the core first-stage arrow body 3. Three circumferential engines 2 are evenly arranged along the circumference of the middle engine 1. The middle engine 1 and the three The thrust directions of the circumferential engines 2 are all parallel to the axis of the core first-stage rocket body 3, that is, the middle engine 1 and the three circumf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com