Flexible normalization device

A correcting device and flexible technology, applied in the field of flexible correcting mechanical devices, can solve problems such as low adjustment accuracy, unstable work, screw correction failure, etc., to achieve self-adjustment and correction, good work stability, Reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

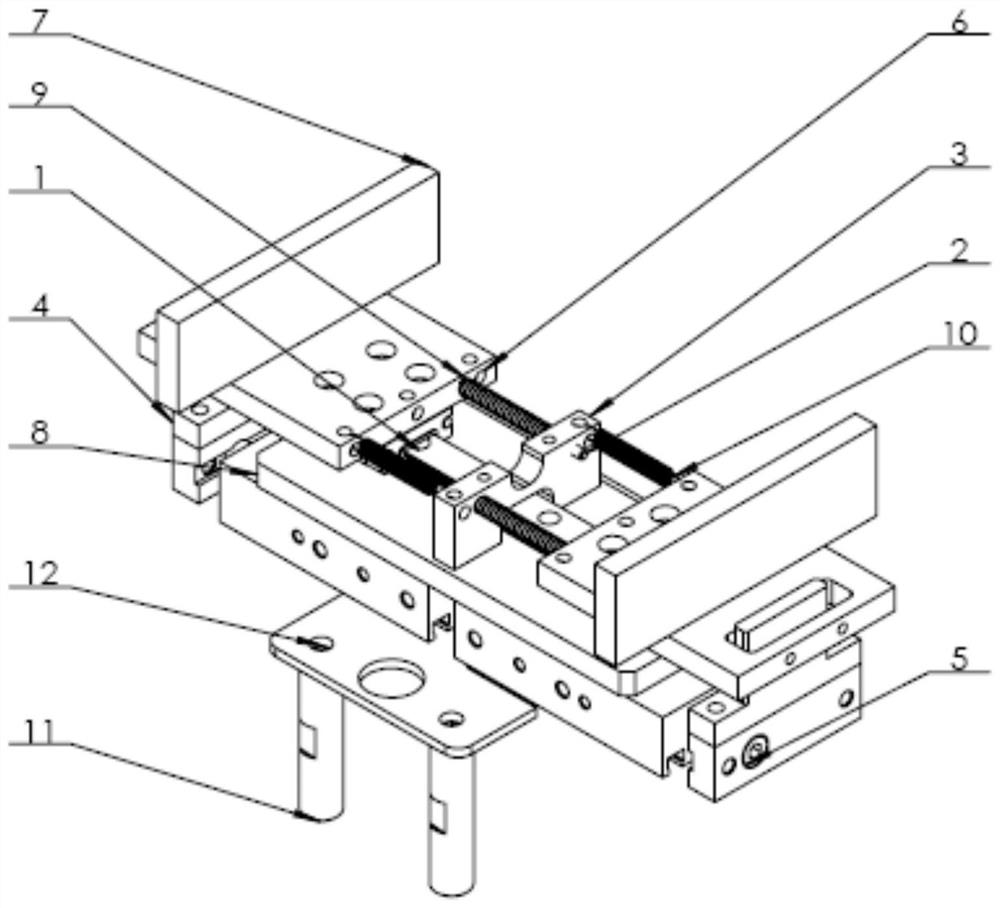

[0007] like figure 1 As shown, the present invention has a double slider guide rail 1, two buffer rods 2, a fixed plate 3, two driving rods 4, two cylinders 5, two limit blocks 6, two normalization blocks 7, A normalizing transition plate 8, two compression springs 9, two extension springs 10, four standing columns 11, an adapter plate 12; the two normalizing blocks 7 and two limit blocks 6 and one The double-slider guide rail 1 is fixed to the normalizing transition plate 8 by screws and is symmetrical left and right, the fixed plate 3 and the normalizing transition plate 8 are fixed by screws, and one end of the two buffer rods 2 is threaded so as to be directly fixed on the On the fixed plate 3; the two clip springs 9 are set on the fixed plate 3 to prevent falling off, and the two spacer blocks 6 are connected with the fixed plate 3 by two extension springs 10. The two cylinders 5 are connected with the adapter plate 12 and the normalization transition plate 8 by screws, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com