A kind of preparation method of stalactite-like macroporous activated carbon

A technology of activated carbon and stalactite, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of long activation time, high energy and protective gas consumption, high activation temperature, etc., to achieve fast reaction speed and shorten The effect of activation time and low ambient temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method for stalactite-like macroporous activated carbon, comprising the following steps:

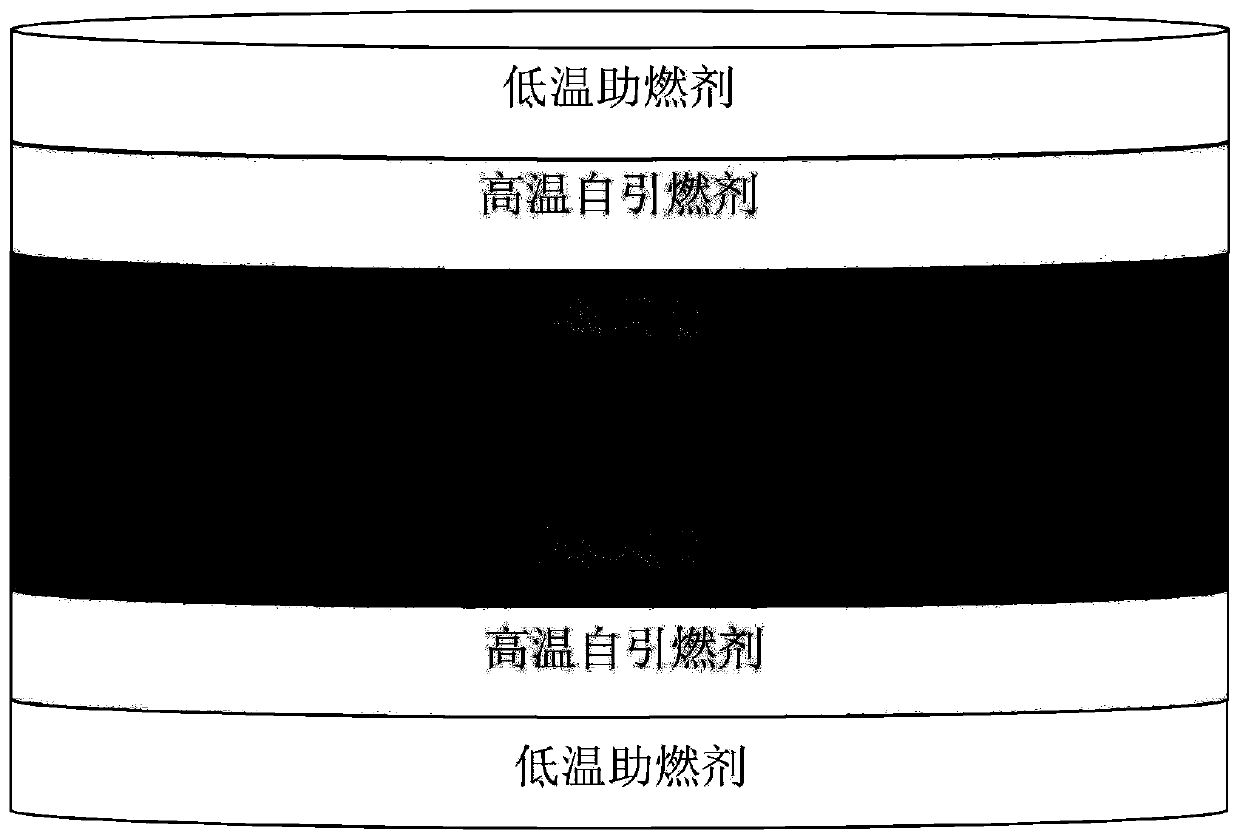

[0038] (1) According to the mass ratio of 1:5, take activated carbon and potassium hydroxide with a total mass of 180g as the activated activated carbon precursor, and place it in a ball mill tank with a rotating speed of 200r / min to 1200r / min for 15min to 2h to mix evenly. Divide into 10 parts on average, each part is 18g, and then press the activated activated carbon precursor after ball milling into a sheet, and set a heat-conducting substrate on both sides so that it is between two heat-conducting substrates;

[0039] (2) Take iron powder and potassium perchlorate as high-temperature self-ignition agent according to the mass ratio of 83:17, after being pressed into a sheet, place the outer surface of the above-mentioned heat-conducting substrate without activated activated carbon precursor; described potassium perchlorate as oxidant;

[0040] (3) Weigh zirconium...

Embodiment 2

[0044] A preparation method for stalactite-like macroporous activated carbon, comprising the following steps:

[0045] (1) According to the mass ratio of 1:5, take 180g of activated carbon and potassium hydroxide as the precursor of activated activated carbon, and place them in a ball mill tank with a rotation speed of 200r / min to 1200r / min for 15min to 2h to mix evenly. Divide into 10 parts, each part 18g, and then press the activated activated carbon precursor after ball milling into a sheet, and set a heat-conducting substrate on both sides so that it is between two heat-conducting substrates;

[0046] (2) Take iron powder and potassium perchlorate as high-temperature self-ignition agent according to the mass ratio of 83:17, after being pressed into a sheet, place the outer surface of the above-mentioned heat-conducting substrate without activated activated carbon precursor; described potassium perchlorate as oxidant;

[0047] (3) Weigh zirconium and barium chromate as a l...

Embodiment 3

[0051] A preparation method for stalactite-like macroporous activated carbon, comprising the following steps:

[0052] (1) According to the mass ratio of 1:4, take 180g of activated carbon and potassium hydroxide as the precursor of activated activated carbon, and place them in a ball mill tank with a rotation speed of 200r / min to 1200r / min for 15min to 2h to mix evenly. Divide into 10 parts, each part 18g, and then press the activated activated carbon precursor after ball milling into a sheet, and set a heat-conducting substrate on both sides so that it is between two heat-conducting substrates;

[0053] (2) take iron powder and sodium perchlorate as high-temperature self-ignition agent according to the mass ratio of 83:17, after being pressed into a sheet, place the outer surface of the non-activated activated carbon precursor of the above-mentioned heat-conducting substrate; Sodium chlorate as an oxidizing agent;

[0054] (3) Weigh zirconium and barium chromate as a low-te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com