Safe iron device for clothing ironing

An iron and ironing technology, applied in the field of clothing manufacturing, can solve problems such as scalding, scalding clothing, fire, etc., and achieve the effects of smooth up and down sliding, reduced operation force, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

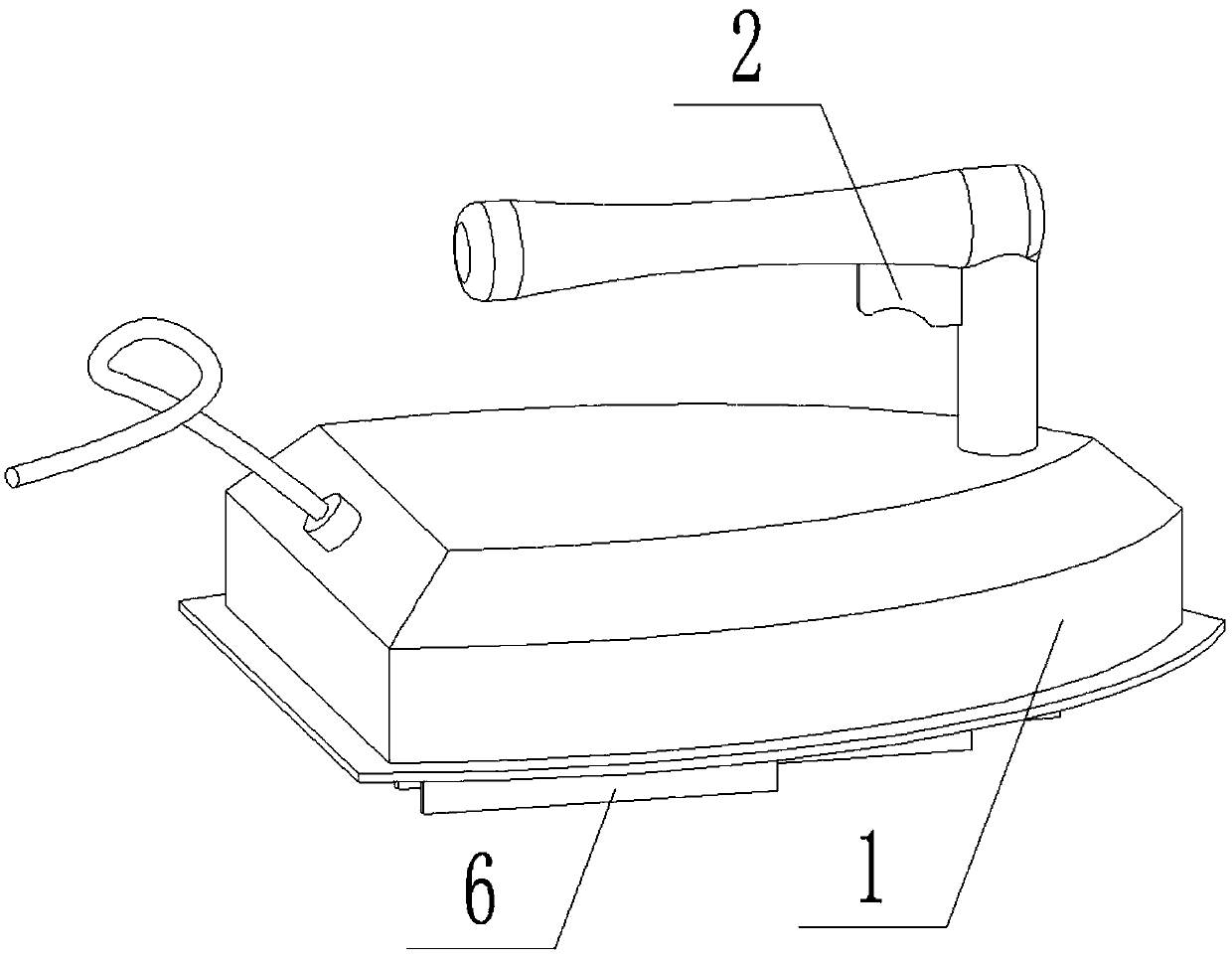

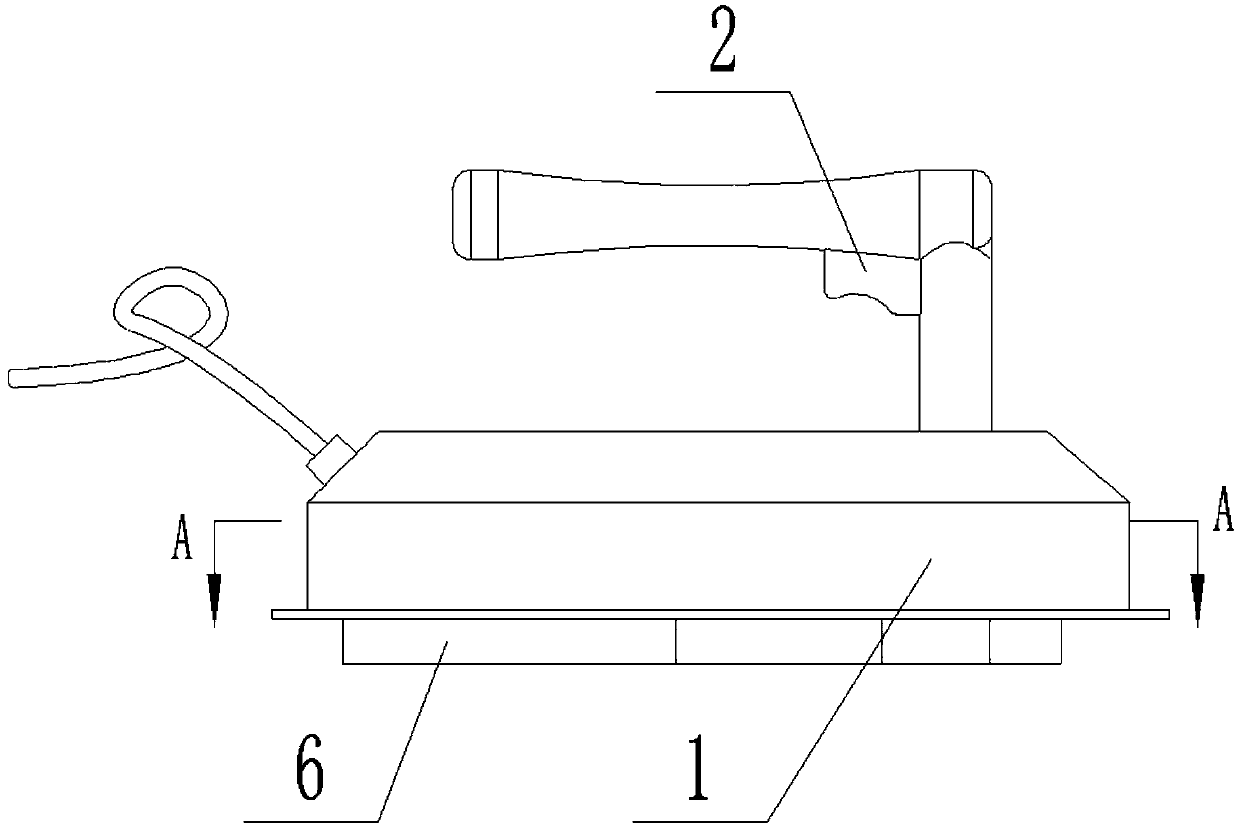

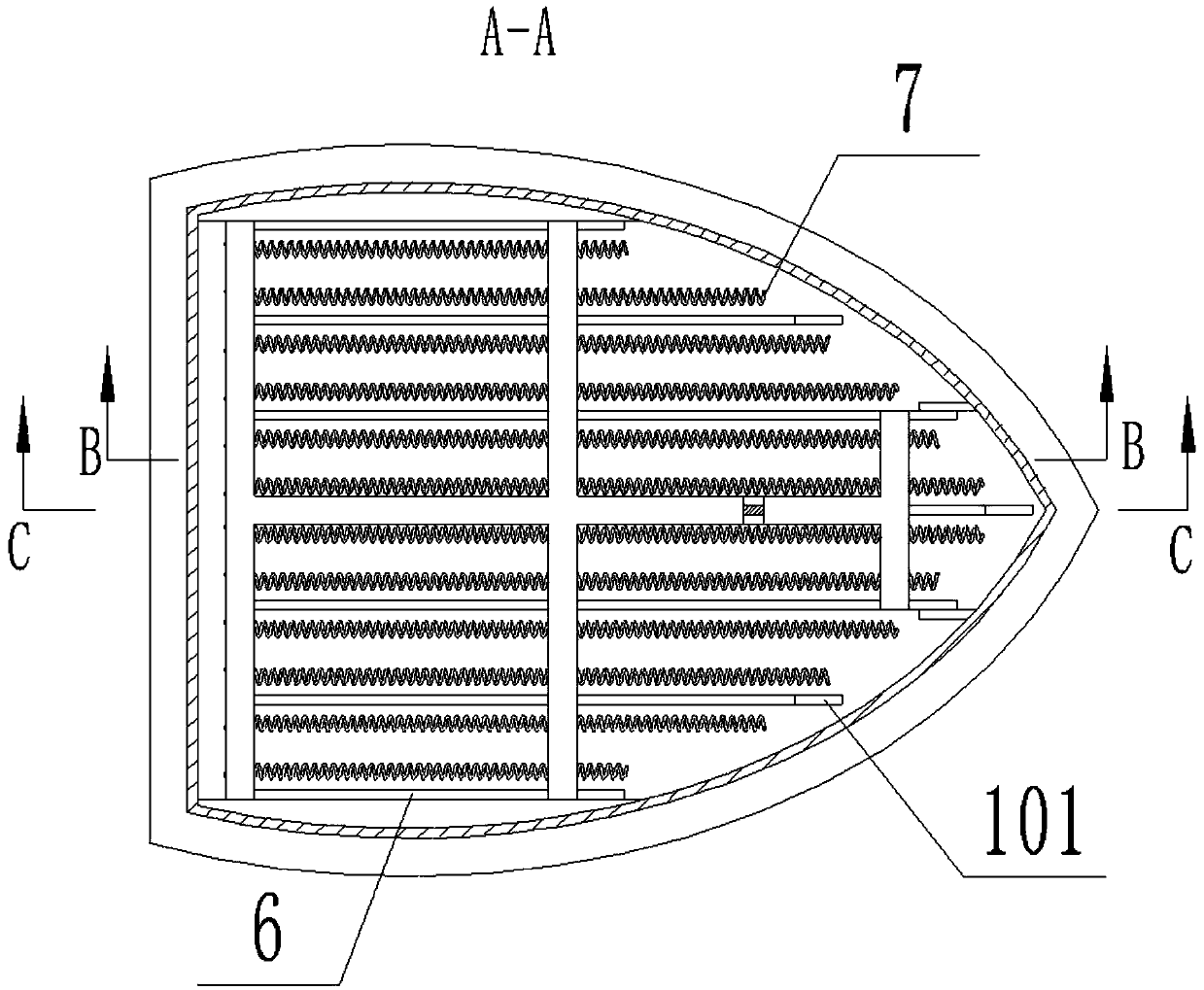

[0032] as attached figure 1 to attach Figure 8 Shown:

[0033] The present invention provides a safety ironing device for ironing clothes, including: an iron body 1, a support plate groove 101, a support plate chute 102, a button 2, a chute 201, a spring 3, a lifting crank 4, a lifting rocker 5, Support plate 6, pulley 601 and electric heating tube 7; a set of buttons 2 is slidably connected to the inside of the handle of the iron body 1; the top of the button 2 is elastically connected to the handle of the iron body 1 through three sets of springs 3; the bottom of the button 2 is hinged. There is a group of lifting cranks 4; the right end of the lifting cranks 4 is hingedly connected to the iron body 1; a group of support plates 6 is slidably connected to the bottom of the iron body 1; a group of lifting rockers 5 is hingedly connected to the top of the supporting plates 6; The iron main body 1 is hinged; the lifting rocker 5 is hinged to the lifting crank 4; the bottom su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com