Dewatering enclosure structure of steel pipe larssen sheet piles

An enclosure structure, Larsen steel sheet pile technology, applied in the direction of sheet pile walls, foundation structure engineering, excavation, etc., can solve the problems of foundation pit enclosure safety hazards, delays in construction period, and difficulties in earthwork excavation, so as to improve the integrity of the structure And closed, easy to operate, the effect of simple construction principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

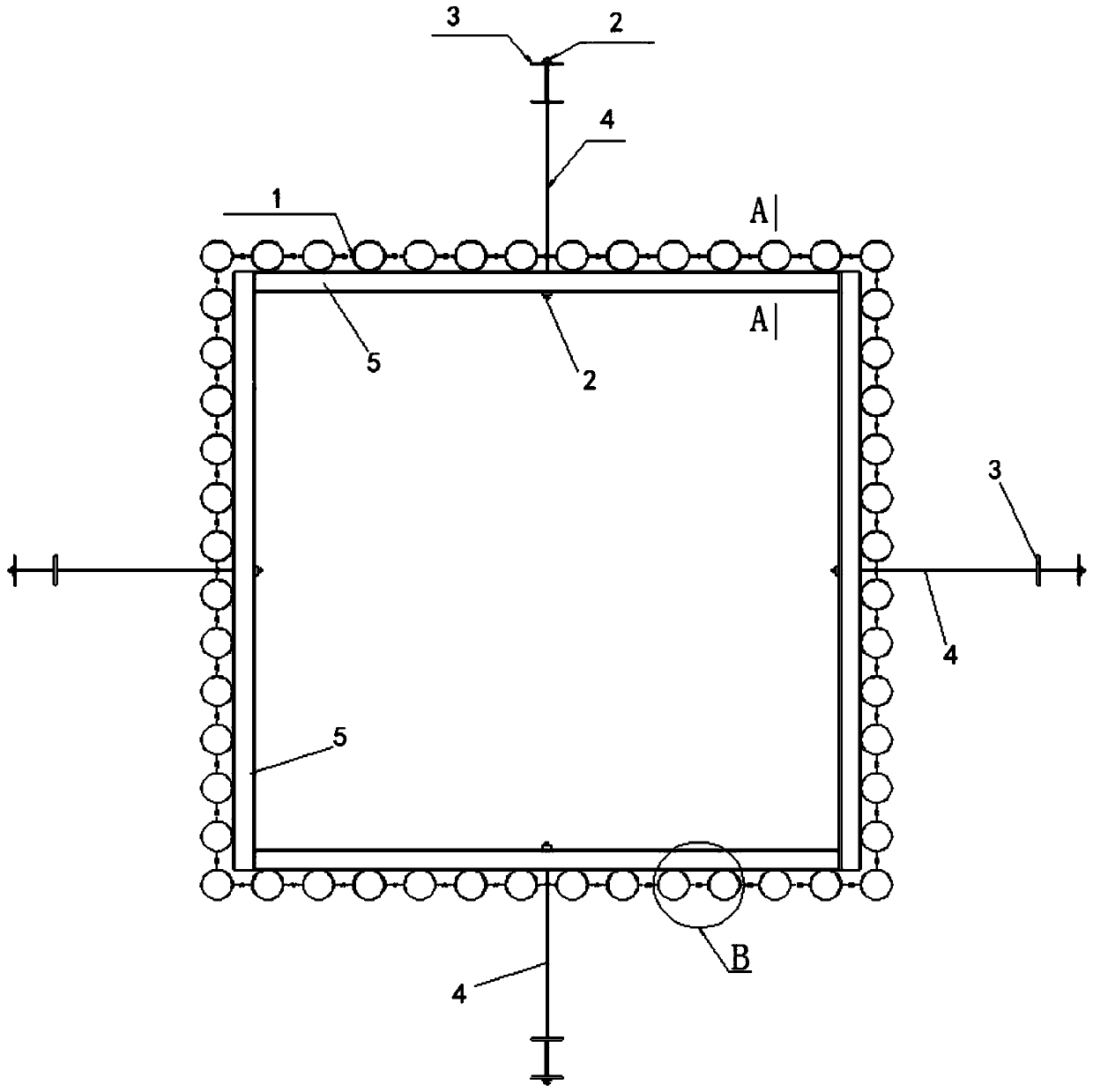

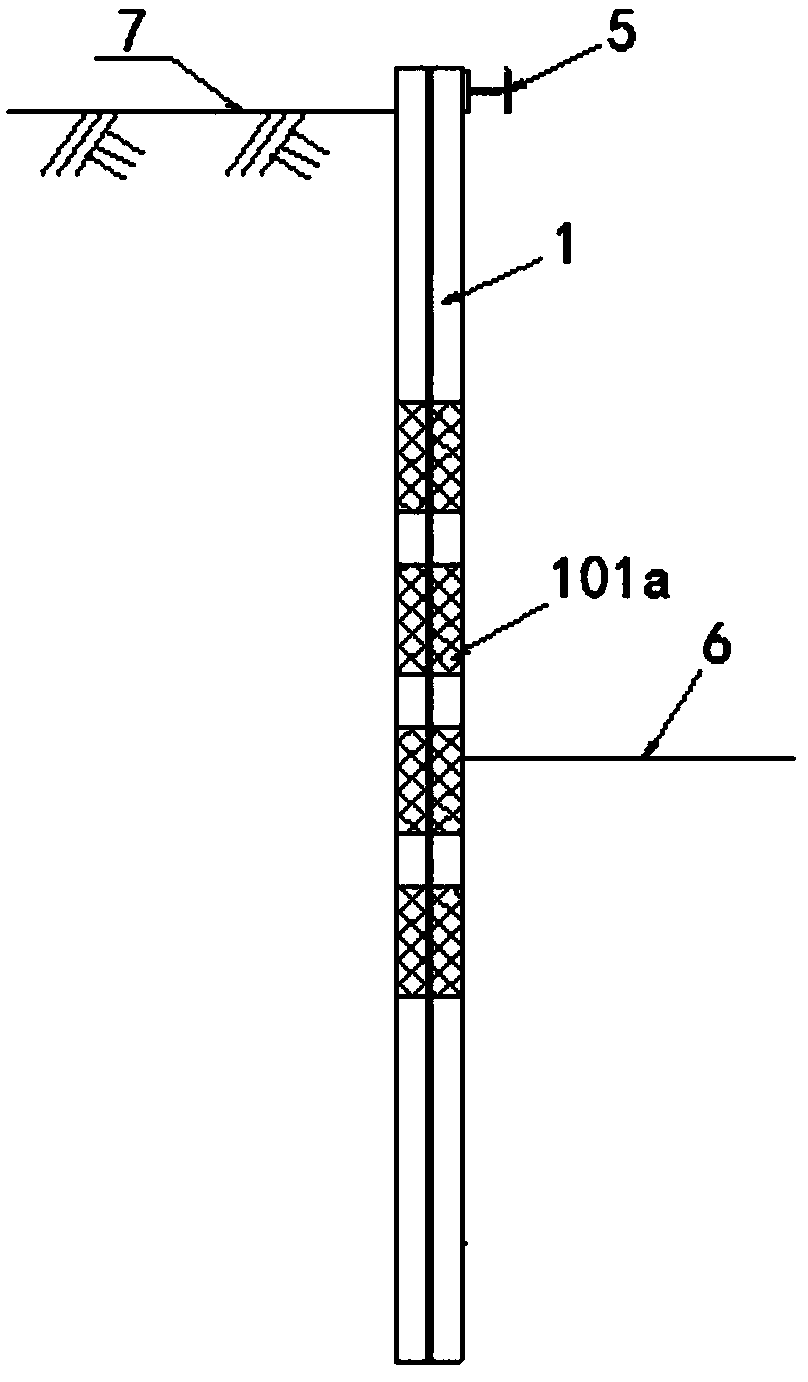

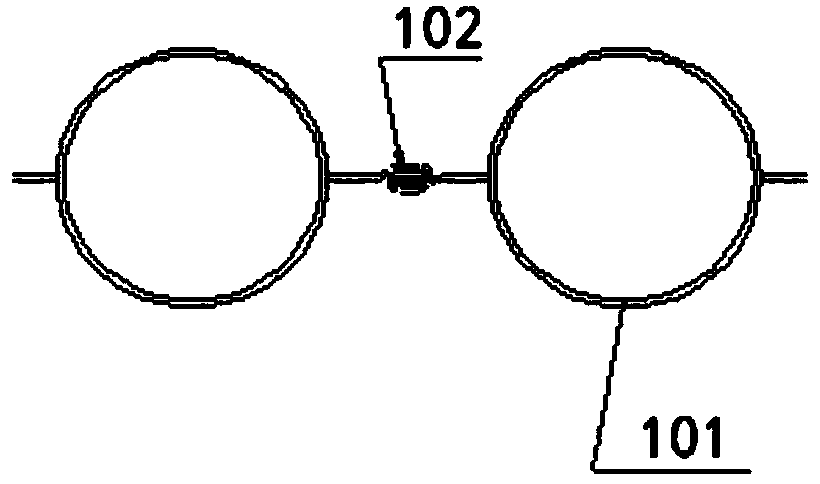

[0022] Figure 1 to Figure 3 A preferred embodiment of the steel pipe Larsen sheet pile precipitation containment structure of the present application is shown, which includes a plurality of steel pipe Larsen plates arranged around the side walls around the foundation pit to form a closed enclosure Pile 1. Each steel pipe Larsen sheet pile 1 is composed of a steel pipe 101 and a Larsen steel sheet pile 102 welded on both radial sides of the steel pipe. The Larsen steel sheet piles 102 on two adjacent steel pipe Larsen sheet piles 1 are mutually Snap connection. The outer side of the aforementioned enclosure is provided with anchoring steel 3 driven into the ground, and the inner side of the closed enclosure is provided with a steel purlin 5 that is arranged adjacent to the steel pipe Larsen sheet pile 1, and the steel purlin 5 passes through the anchoring steel 3 Anchor cable 4 is fastened and connected.

[0023] The so-called "one breaking and two welding" refers to breaki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com