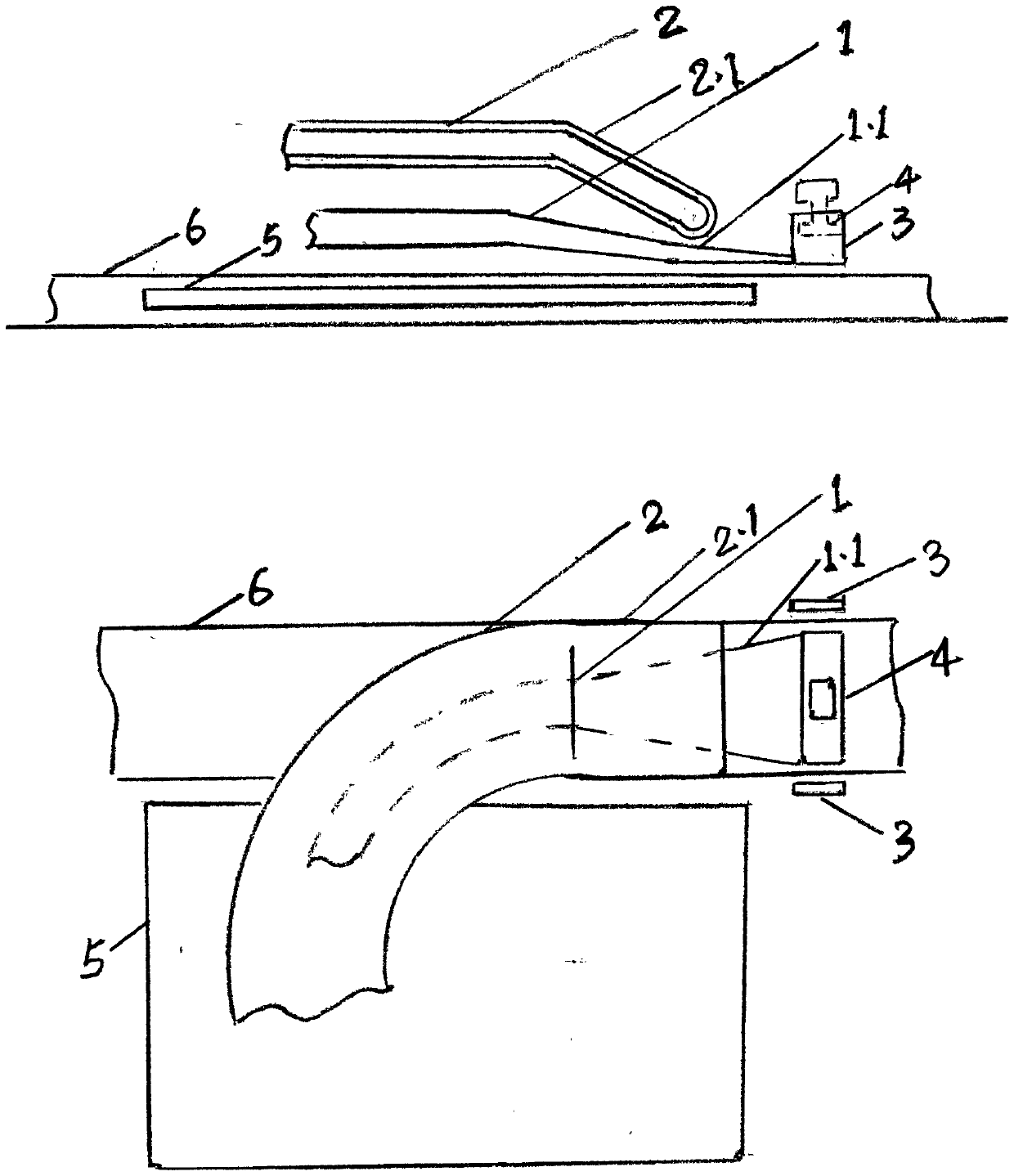

Automatic wall building and pavement bricklaying machine

A brick-laying machine and wall-laying technology, which is applied in the direction of roads, roads, road repairs, etc., can solve the problems of poor road surface firmness, limited use, and limited work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

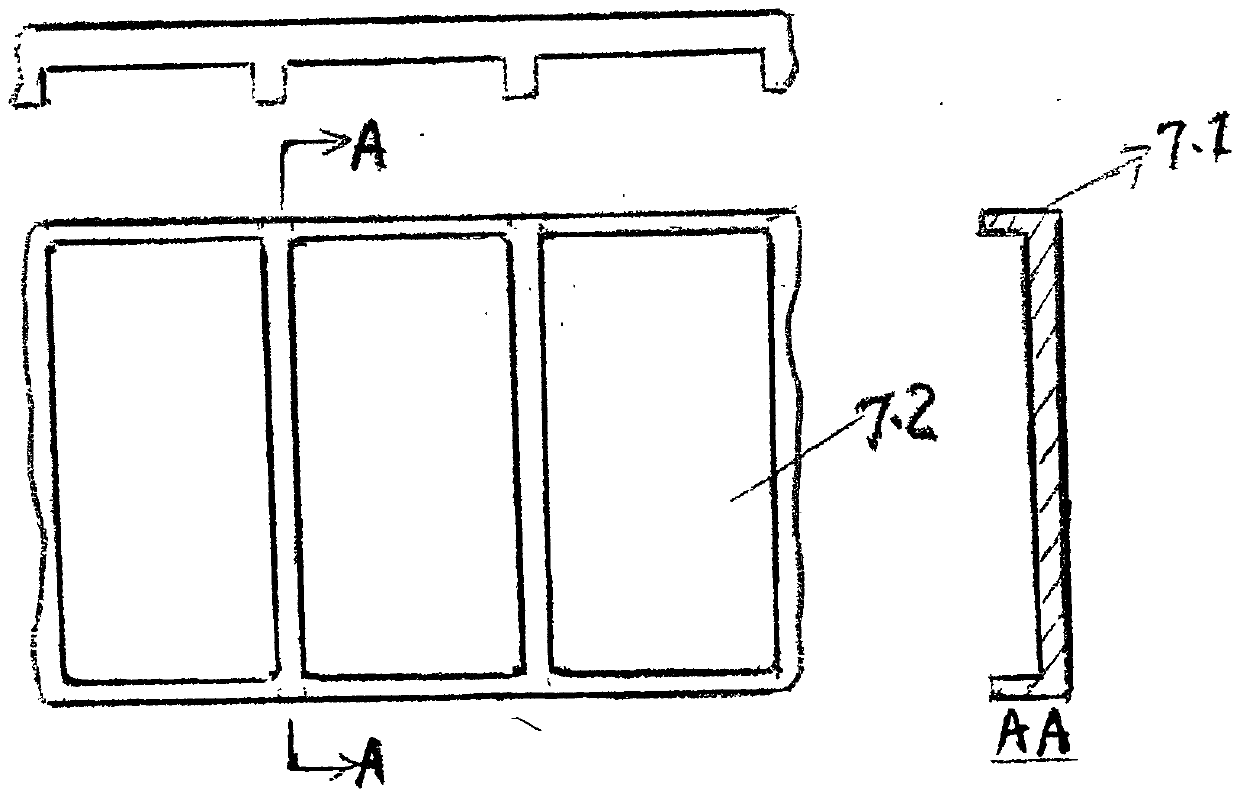

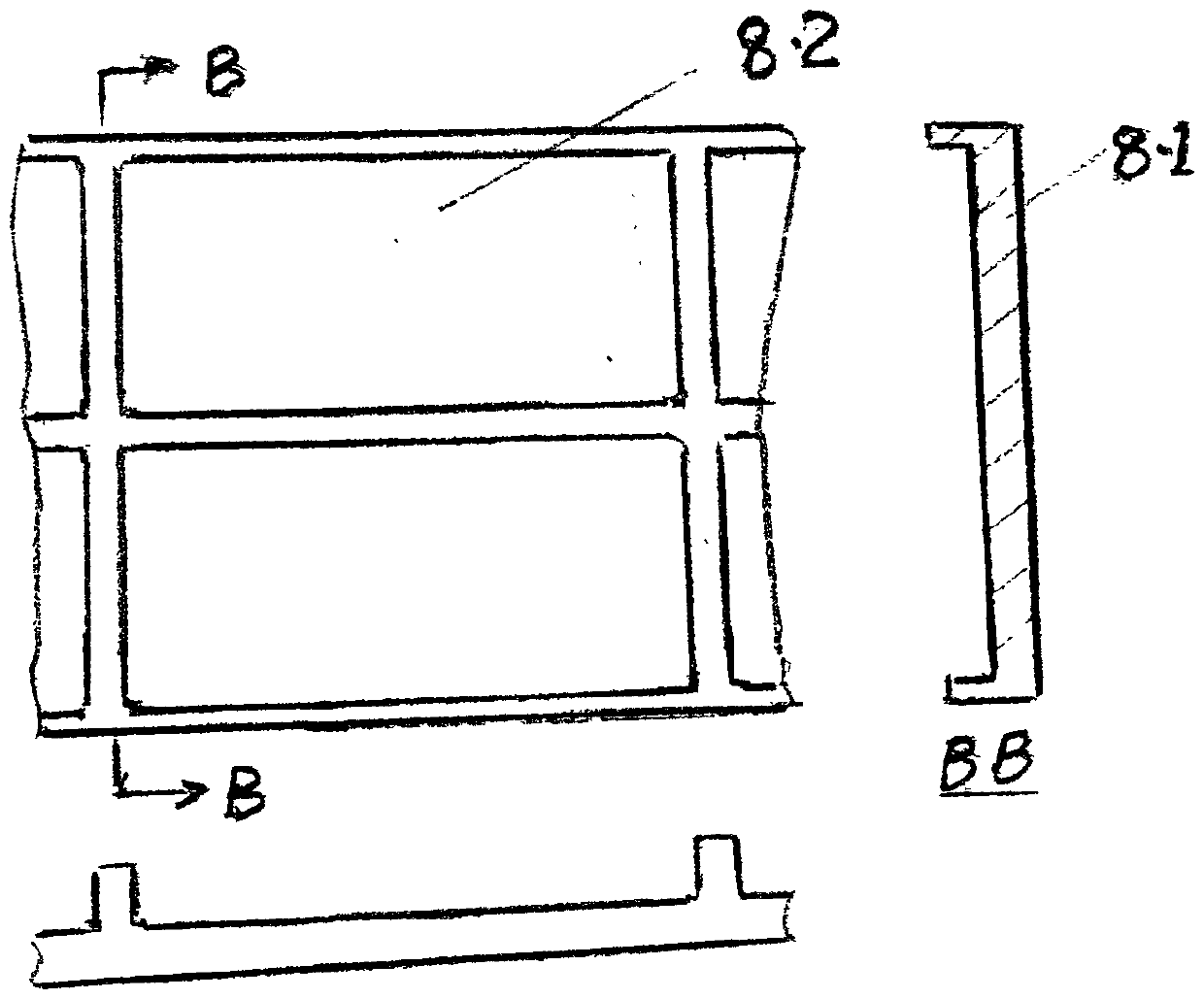

[0013] Single-frame single-grid frame strips and single-frame double-grid or multi-grid frame strips are all special-purpose frame strips. The number, shape and size of the single frame of the frame strips are determined according to the wall surface to be built. This kind of frame belt turns many scattered bricks to be laid into a neat brick belt, so that high-quality and rapid wall building can be realized. Framework (7.1) or (8.1) and adorn brick space (7.2) or (8.2) are arranged on frame belt. The frame belt can be made of plastic materials. In order to ensure smooth turning of the conveying, the two sides should have certain elasticity. A kind of specific implementation is: first make some single frames of plastics, then use elastic material band to connect many single frames into a strip-shaped frame belt. The adorn brick space (7.2) or adorn brick space (8.2) on the frame band are used for adorn brick. This frame belt can be made into a frame belt for adorning various...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com