A new pipeline defect repair method and repair equipment

A technology for repairing defects and pipelines, which is applied in the direction of mechanical equipment, pipe components, pipes/pipe joints/fittings, etc., can solve the problems of high technical level, poor construction flexibility, and high repair costs, and achieve flexible repair operations, high repair costs, Outstanding effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0047] Material: The repair material is the same as the steel grade of the pipe body or higher. Colloid: The colloid is a high-strength glue with strong bonding force and short gelation time;

[0048] Repair method: Use a 200mm wide thin steel plate of the same steel grade as the conveying pipe body or a higher steel grade and high-strength sealant to tightly wind the surface-treated pipe body in the same direction, and carry out simultaneous Glue brushing and winding in the same direction; the beginning of winding is 100mm beyond the defect to be repaired, and the end is wrapped 3-5 times at the same end, and then the oblique winding is started, with a diagonal distance of 5-8mm. The terminal is 100mm beyond the defect to be repaired. -5 laps.

example 2

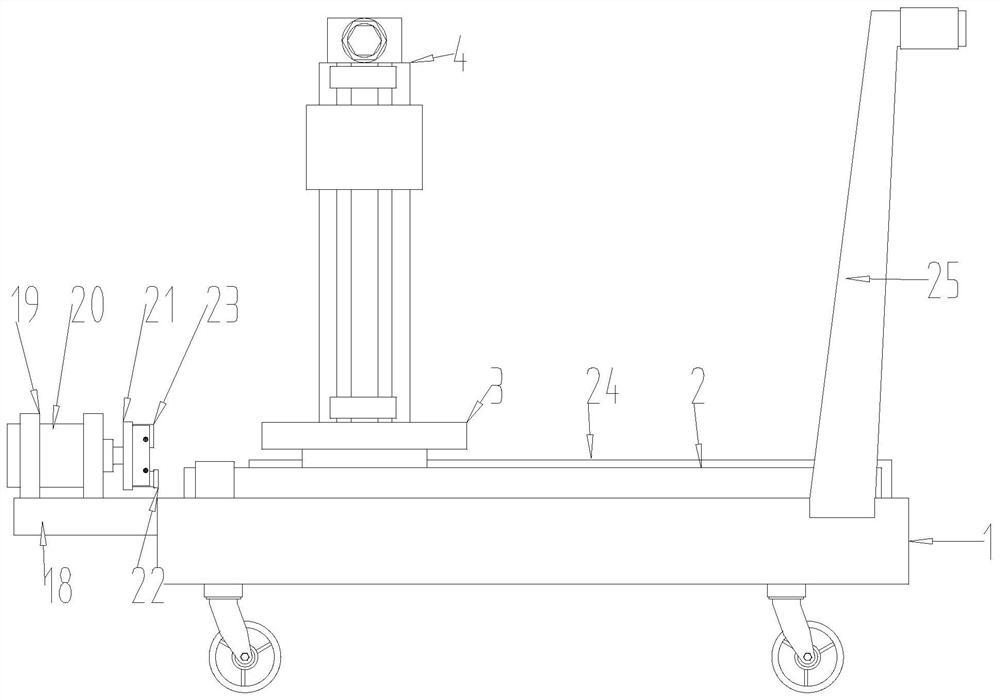

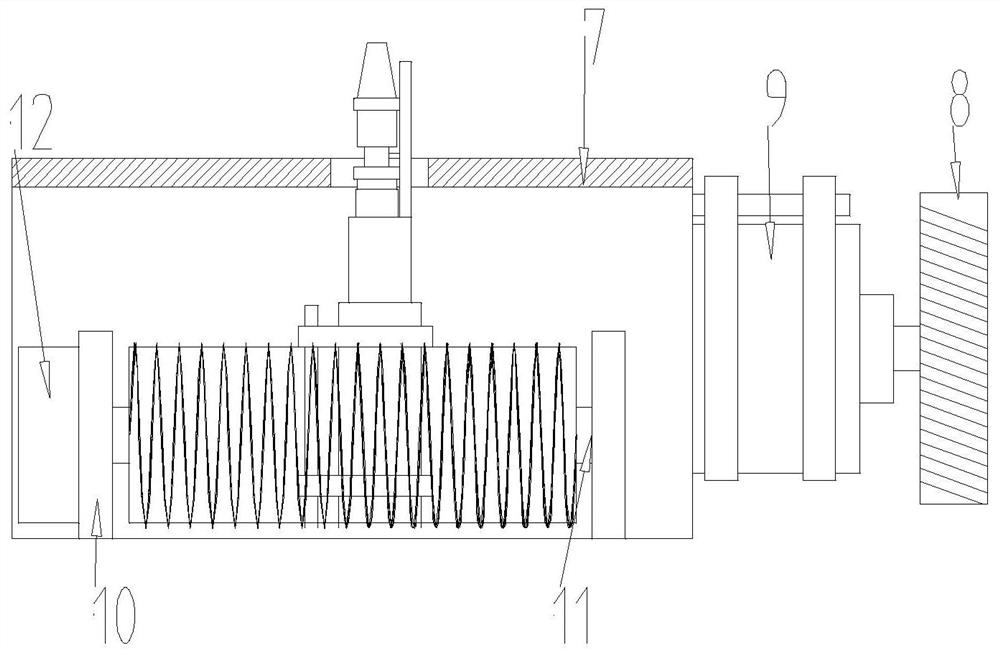

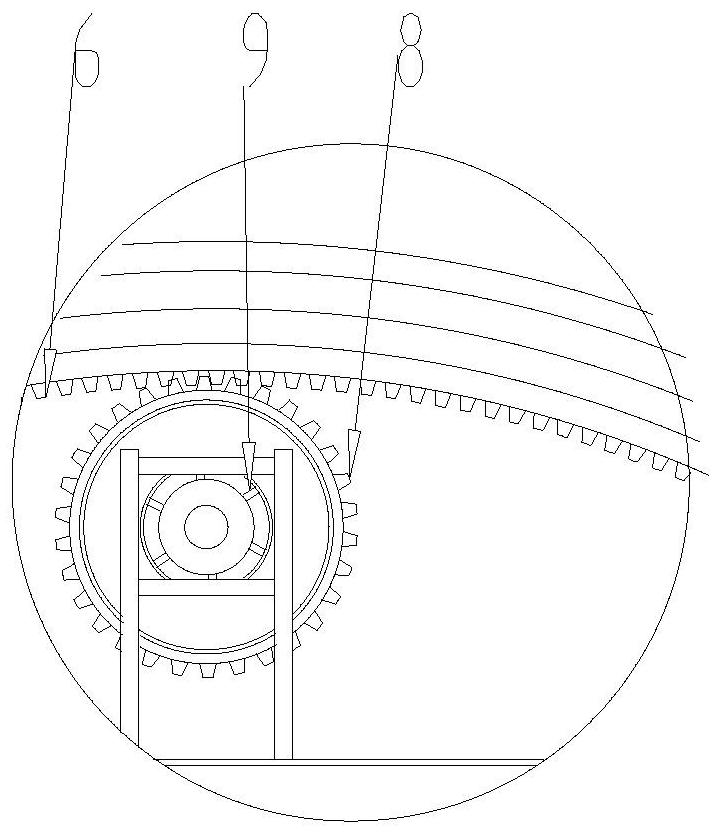

[0050] First, the detachable annular support frame 4, the circular slide rail 5 and the internal gear 6 are all set on the pipeline, and installed and fixed, and then powered by the battery 22, and the work sequence is controlled by the controller 23. First, the telescopic motor 16 Push the installation frame 14 down, the electric push rod 15 pushes the push end on the glue gun 17, the glue is extruded and painted on the pipe, and then the winding motor 12 is controlled to work, and the shaft body 11 is driven to make the glue on the material sleeve 13 The repair material is moved out of the installation box 7, and one end of the repair material is manually fixed on the surface of the pipeline, and the inner gear 6 is driven by the feed motor 9 to mesh with the outer gear 8. Since the installation box 7 is fitted on the circular slide rail 5, the installation The box 7 rotates to realize the winding of the repair material. After winding 3-5 times, the linear module translation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com