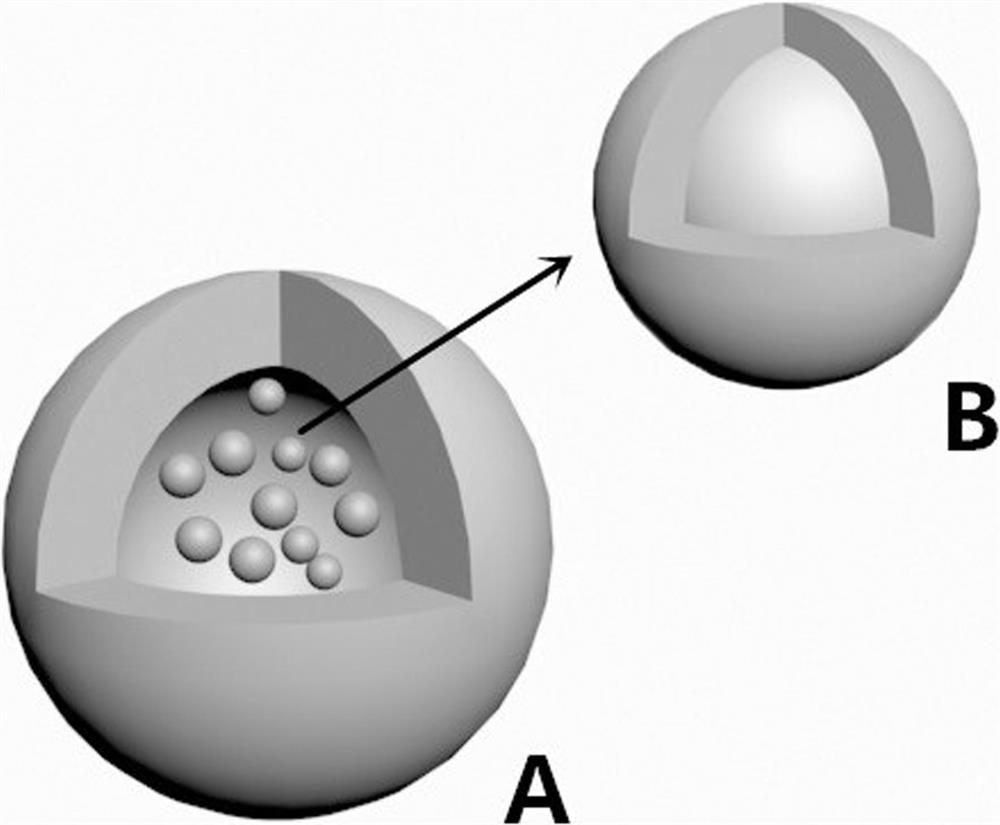

External repair and internal solid self-repairing microcapsules with cellular structure and preparation method thereof

A self-healing microcapsule and cell-like structure technology, applied in the field of organic composite materials, can solve problems such as easy deactivation, inability to effectively fill cracks, and easy rupture, so as to reduce the probability of rupture, improve self-healing efficiency, and improve mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

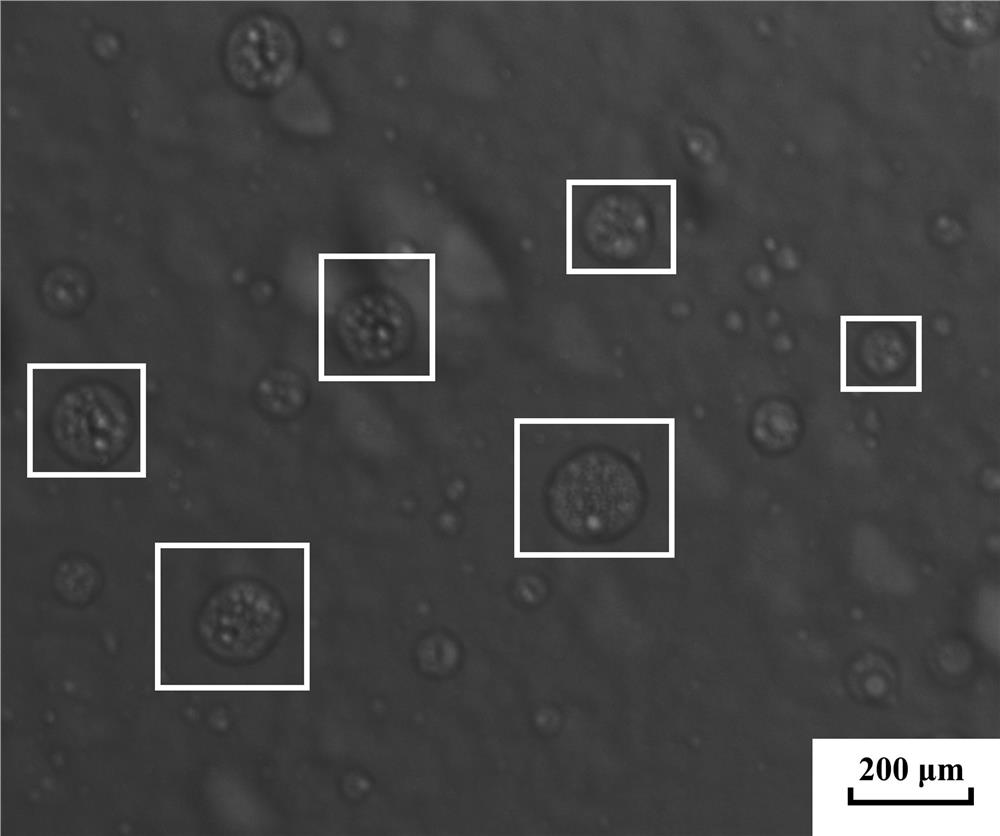

Image

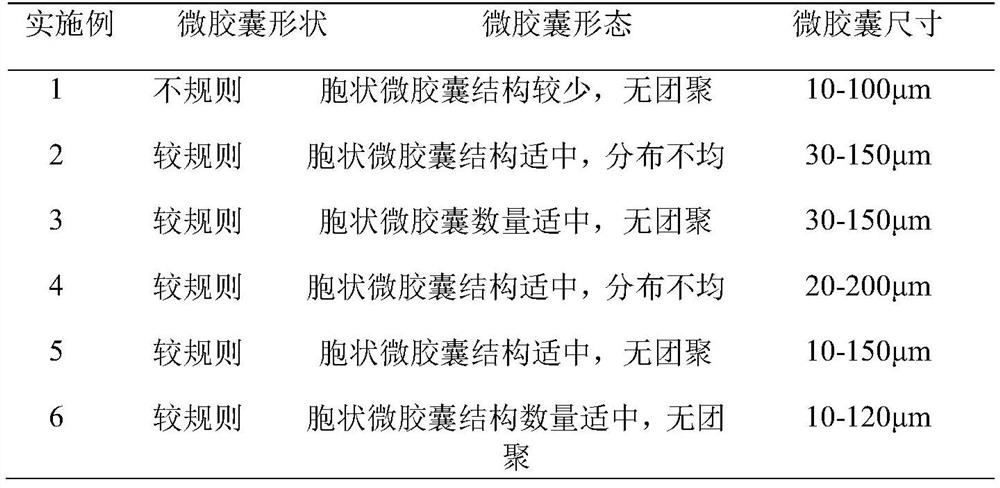

Examples

Embodiment 1

[0037] The preparation method of the self-healing microcapsule with external repair and internal solidification with cellular structure comprises the following steps:

[0038] (1) Preparation of oil-in-water silane emulsion 1:

[0039] (1a) Weigh an appropriate amount of silane, emulsifier and dispersant, the weight ratio of silane, emulsifier and dispersant is 80:1:1, stir at room temperature at a speed of 2000rpm for 30min to obtain a uniformly dispersed oil phase; the silane It is vinyltriethoxysilane, the emulsifier is Op-10, and the dispersant is polyethylene glycol.

[0040] (1b) Weigh an appropriate amount of emulsifier Op-10 and water, the weight ratio of emulsifier and water is 1:110, and stir at 1400rpm at room temperature for 26min to obtain a composite water phase;

[0041] (1c) Gradually drop the oil phase into the water phase, the weight ratio of the oil phase to the water phase is 1:1.2, and stir at 7000rpm at 44°C for 4h to obtain a uniform and stable oil-in-w...

Embodiment 2

[0053] Different from Example 1, the preparation method of the externally repaired and internally solidified self-repairing microcapsules with a cellular structure comprises the following steps:

[0054] (1) Preparation of oil-in-water silane emulsion 1:

[0055] (1a) Weigh an appropriate amount of silane, emulsifier and dispersant, the weight ratio of silane, emulsifier and dispersant is 100:2:1, and stir at room temperature for 26min at a speed of 2400rpm to obtain a uniformly dispersed oil phase; the silane It is vinyltrimethoxysilane, the emulsifier is polyvinyl alcohol, and the dispersant is potassium citrate.

[0056] (1b) Weigh an appropriate amount of emulsifier polyvinyl alcohol and water, the weight ratio of emulsifier and water is 1:120, and stir at 1800rpm at room temperature for 22min to obtain a composite water phase;

[0057] (1c) Gradually drop the oil phase into the water phase, the weight ratio of the oil phase to the water phase is 1:1.4, and stir at 8000rp...

Embodiment 3

[0069] Different from Example 1, the preparation method of the externally repaired and internally solidified self-repairing microcapsules with a cellular structure comprises the following steps:

[0070] (1) Preparation of oil-in-water silane emulsion 1:

[0071] (1a) Weigh an appropriate amount of silane, emulsifier and dispersant, the weight ratio of silane, emulsifier and dispersant is 120:2.5:1, and stir at room temperature for 22min at a speed of 2800rpm to obtain a uniformly dispersed oil phase; the silane It is isobutyltriethoxysilane, the emulsifier is sodium dodecylbenzenesulfonate, and the dispersant is sodium linoleate.

[0072] (1b) Take an appropriate amount of emulsifier sodium dodecylbenzenesulfonate and water, the weight ratio of emulsifier and water is 1:105, and stir at 2200rpm at room temperature for 20min to obtain a composite water phase;

[0073] (1c) Gradually drop the oil phase into the water phase, the weight ratio of the oil phase to the water phase ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com