Polymer matrix composite bottle cap and preparation method thereof

A composite material and polymer technology, applied in the field of bottle caps, can solve problems such as poor anti-counterfeiting performance, achieve the effect of improving anti-counterfeiting ability, protecting interests, and preventing wear and scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

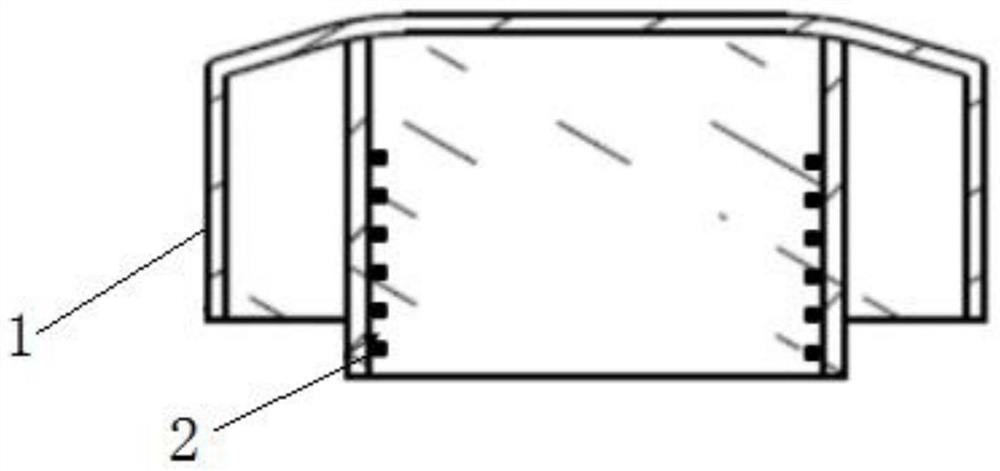

[0028] Embodiment 1: as figure 1 As shown, a polymer-based composite material bottle cap includes a cap body 1 and a bottle cap thread 2 arranged inside the cap body 1, the described cap body 1 is a polymer-based composite material cap body, and the described polymer The base composite material cover is composed of a base material and a reinforcing material. The base material includes epoxy resin, vinyl resin, unsaturated polyester resin, phenolic resin, cyanate resin, bismaleamide resin, polysulfone resin, polyether Sulfone resin, polyphenylene sulfide resin, polyetherimide resin, polyether ether ketone resin or polycarbonate; reinforcement materials include carbon fiber, glass fiber, aramid fiber, ceramic fiber or high molecular weight polyethylene fiber.

[0029] The cover body 1 in this example is a carbon fiber cover body. Positioning chips such as GPS and Beidou, or product labels, anti-counterfeiting marks, radio frequency chips, etc. are arranged inside or outside the...

Embodiment 2

[0030] Embodiment 2: The difference between this embodiment and Embodiment 1 is that an outer coating is provided on the surface of the cover body 1, and the outer coating plays the role of isolation protection, which can prevent the polymer-based composite material cover body 1 from The resin is oxidized and discolored by direct exposure to the air, while improving the appearance finish of the entire bottle cap, improving the touch and the overall aesthetics and high-end sense of the product. The outer coating can be PU, or PA, or anti-velvet, or pearlescent, or glossy, or silicone, or film, or flame retardant, or Teflon coating. The thickness of the entire outer coating 3 is controlled between 50-200 μm. The thickness of the entire outer coating 3 is controlled between 50-200 μm. Patterns, LOGOs or QR codes can be sprayed on the surface of the outer coating, or between the outer coating and the cover body 1, and are suitable for all colors.

[0031] The preparation method ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com