A kind of corrosion monitoring sensor and its preparation method

A corrosion monitoring and sensor technology, applied in weather resistance/light resistance/corrosion resistance, instruments, measuring devices, etc., can solve problems such as complex erection, corrosion of components, and large differences between the actual environment and the simulated environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

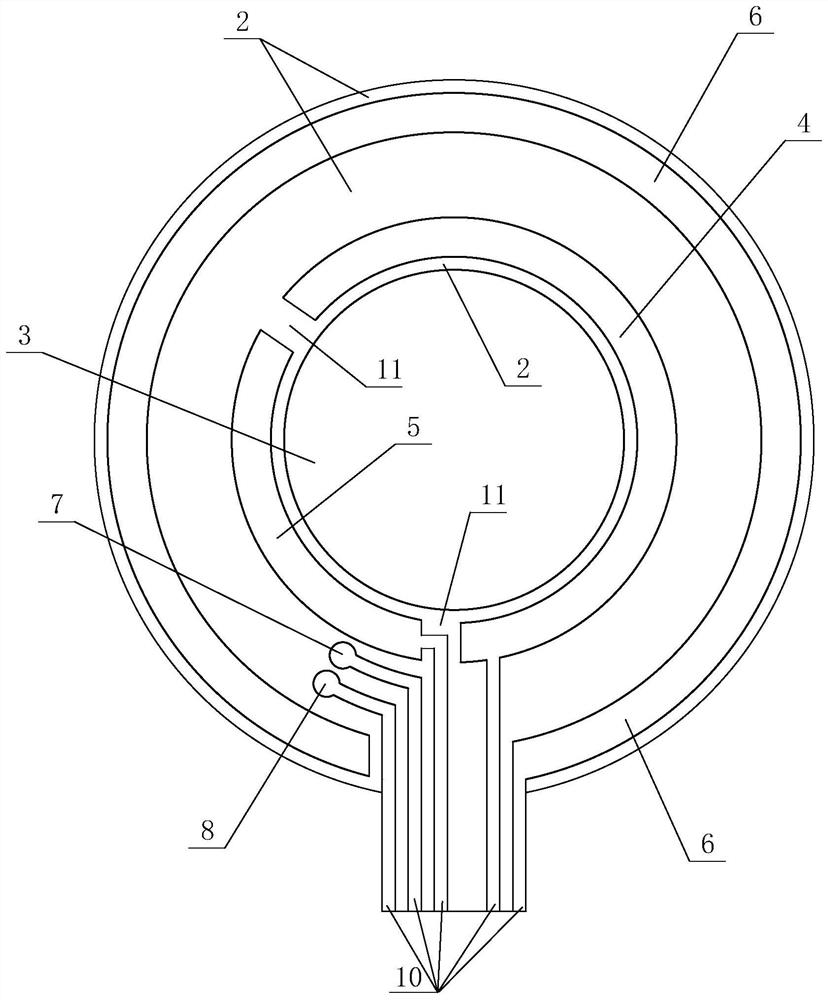

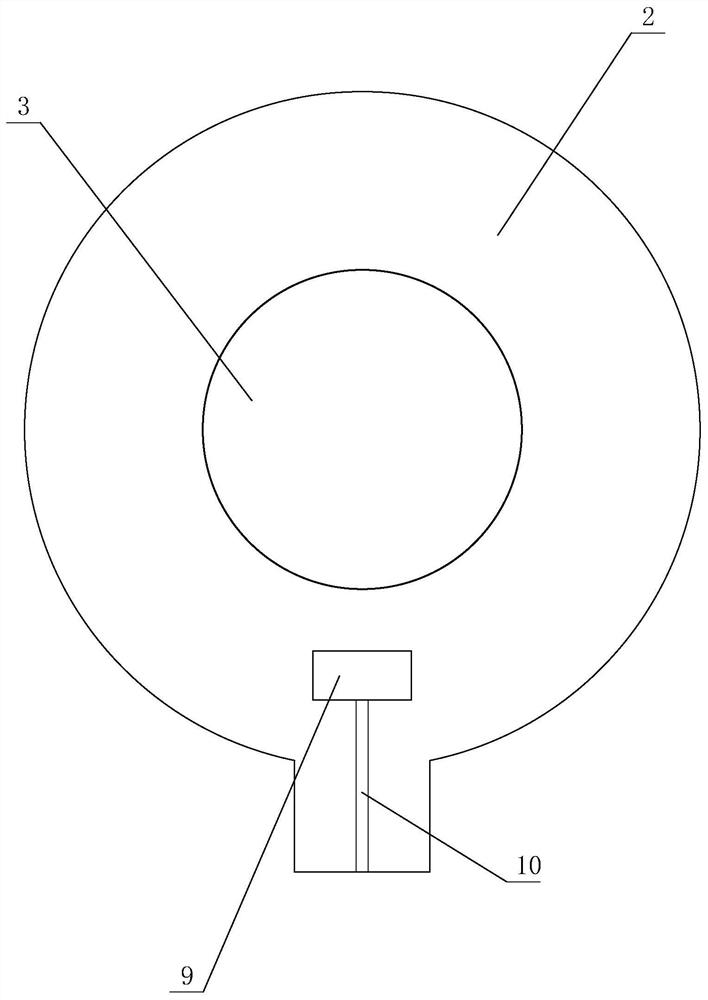

[0067]The corrosion monitoring sensor of the present invention comprises an insulating substrate 2, a current electrode 4, a voltage electrode 5, a shielding electrode one 6, a shielding electrode two 7, a shielding electrode three 8, and a metal connecting piece 9 to be measured;

[0068] The insulating substrate 2 is a polyimide film with a thickness of 0.01mm, and the shape is a rectangle of 30mm×50mm, and a through hole 3 of Φ12mm is opened in the center of the insulating substrate 2;

[0069] The voltage electrode 5 is made of copper;

[0070] The current electrode 4 is made of copper, the outer diameter of the arc is Φ14mm, the inner diameter of the arc is Φ12mm, and the width of the gap 11 is 1.5mm;

[0071] The material of the tested metal connecting piece 9 is copper, and the shape is a rectangle of 5mm×10mm;

[0072] The current electrode 4 , voltage electrode 5 , shielding electrode 1 6 , shielding electrode 2 7 , and shielding electrode 3 8 are located on the fron...

Embodiment 2

[0075] The corrosion monitoring sensor of the present invention comprises an insulating substrate 2, a current electrode 4, a voltage electrode 5, a shielding electrode one 6, a shielding electrode two 7, a shielding electrode three 8, and a metal connecting piece 9 to be measured;

[0076] The insulating substrate 2 is a polyimide film with a thickness of 0.5mm, and the shape is a rectangle of 30mm×50mm, and a through hole 3 of Φ3mm is opened in the center of the insulating substrate 2;

[0077] The voltage electrode 5 is made of copper;

[0078] The material of the current electrode 4 is copper, the outer diameter of the arc is Φ6mm, the inner diameter of the arc is Φ4mm, and the width of the gap 11 is 1.5mm;

[0079] The material of the tested metal connecting piece 9 is copper, and the shape is a rectangle of 5mm×10mm;

[0080] The current electrode 4 , voltage electrode 5 , shielding electrode 1 6 , shielding electrode 2 7 , and shielding electrode 3 8 are located on the...

Embodiment 3

[0083] The corrosion monitoring sensor of the present invention comprises an insulating substrate 2, a current electrode 4, a voltage electrode 5, a shielding electrode one 6, a shielding electrode two 7, a shielding electrode three 8, and a metal connecting piece 9 to be measured;

[0084] The insulating substrate 2 is a polyimide film with a thickness of 0.1mm, and the shape is a rectangle of 30mm×50mm, and a through hole 3 of Φ8mm is opened in the center of the insulating substrate 2;

[0085] The voltage electrode 5 is made of gold;

[0086] The material of the current electrode 4 is gold, the outer diameter of the arc is Φ10.5mm, the inner diameter of the arc is Φ8.5mm, and the width of the gap 11 is 1.5mm;

[0087] The material of the tested metal connecting piece 9 is gold, and the shape is a rectangle of 5mm×10mm;

[0088] The current electrode 4 , voltage electrode 5 , shielding electrode 1 6 , shielding electrode 2 7 , and shielding electrode 3 8 are located on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com